This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Full-service, world-class, global business partner with seamless capabilities in Plastic Injection Molding and Blow/Fill/Seal (B/F/S) aseptic filling for the Healthcare Industry.

We possess a range of manufacturing capacities for the healthcare industry, including advanced plastic injection molding, aseptic filling, and full program management.

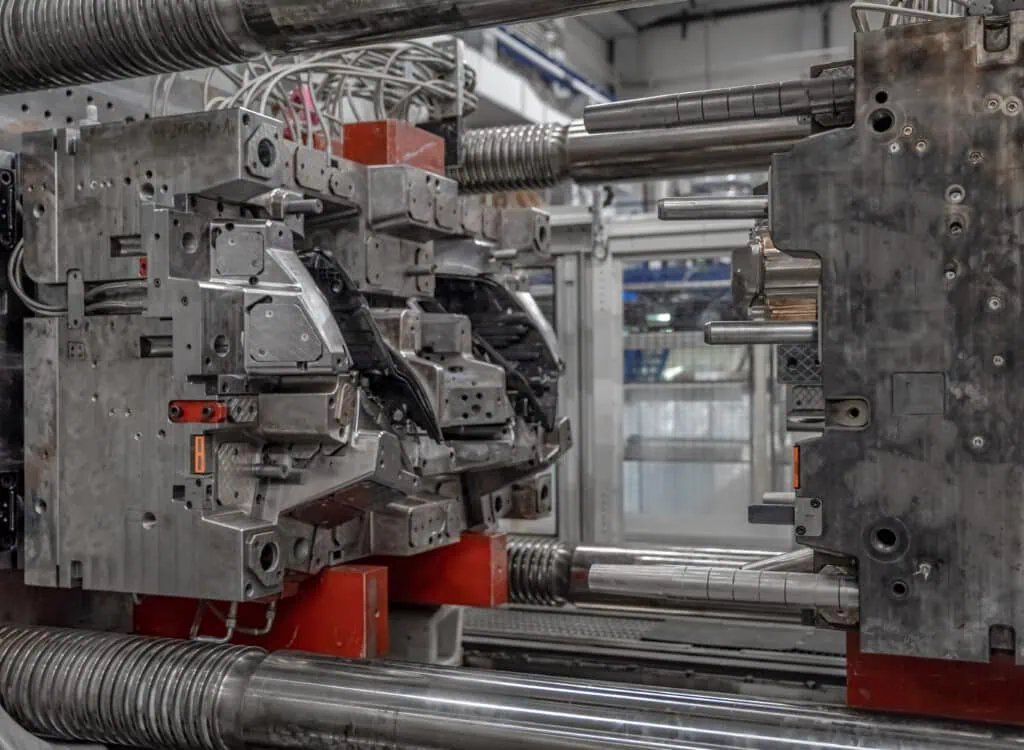

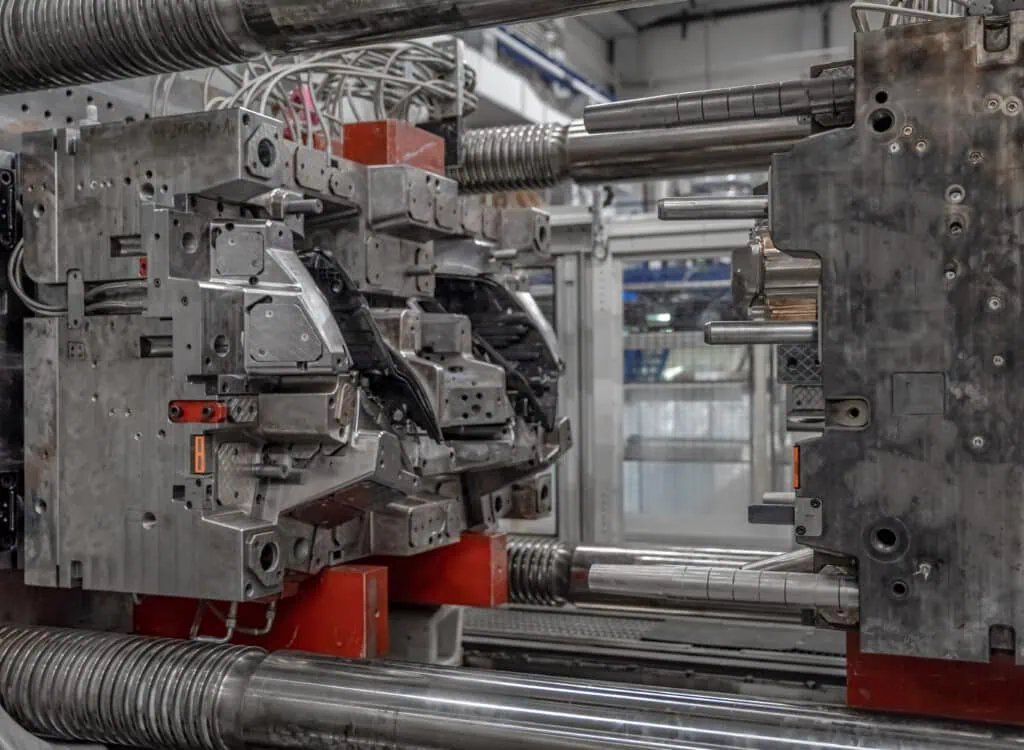

High-precision plastic injection molding for medical devices and pharmaceutical packaging. We support multi-cavity molds, overmolding, and insert molding with tight tolerances.

Learn MoreRapid prototyping using 3D printing, CNC machining, and soft tooling to accelerate time-to-market. We support design validation and regulatory testing.

Learn MoreIn-house mold design and fabrication using advanced CAD/CAM systems. We build high-quality, long-life steel and aluminum molds with quick turnaround.

Learn MoreFull-service engineering support including DFM, FEA, tolerance analysis, and material selection. Our team ensures optimal manufacturability and performance.

Learn MoreBlow/Fill/Seal (B/F/S) technology for sterile liquid packaging in ophthalmic, nasal, and injectable drug delivery. FDA-registered cleanroom environment.

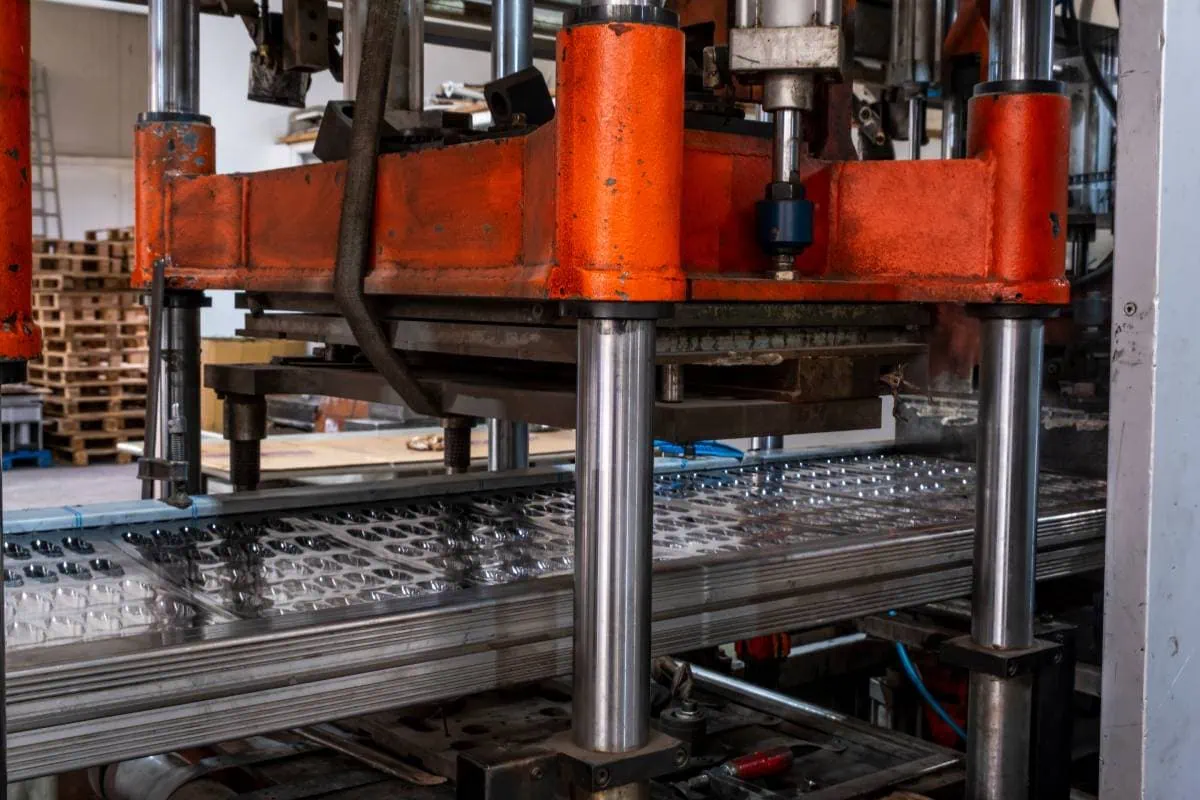

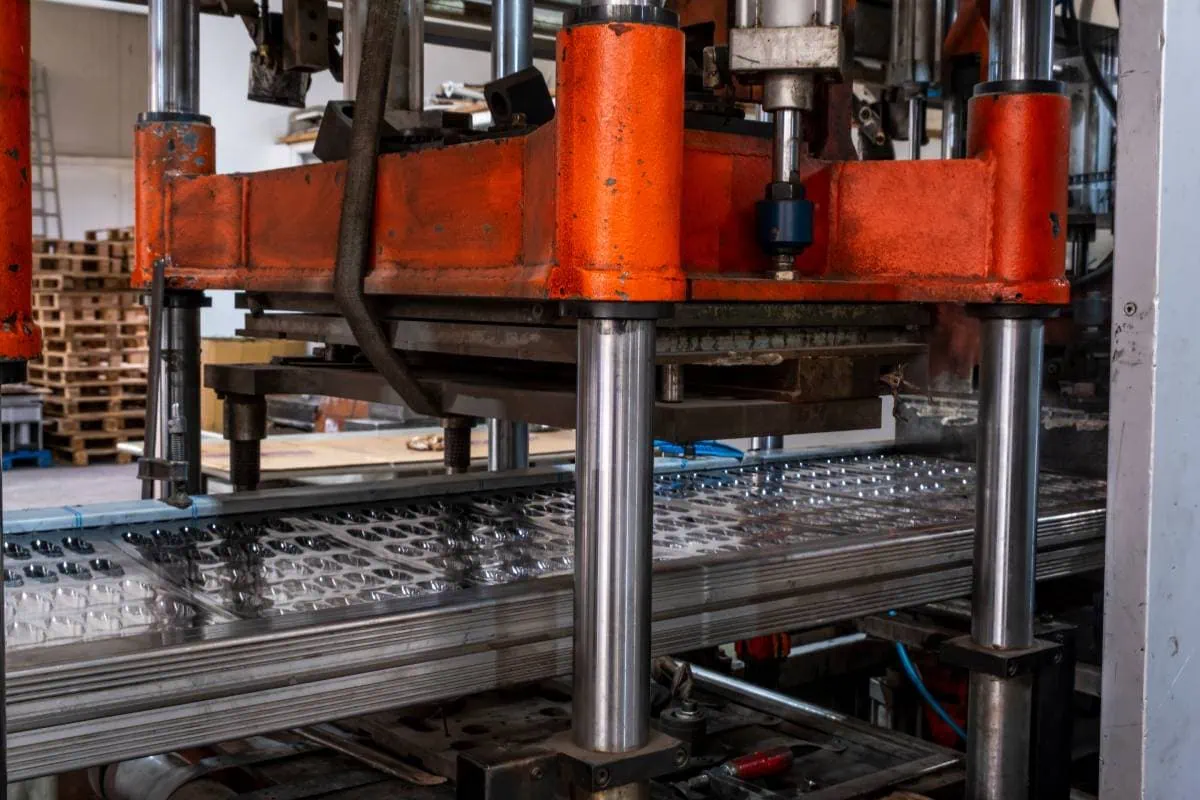

Learn MoreCustom thermoformed packaging and trays for medical devices, diagnostic kits, and surgical instruments. Vacuum and pressure forming available.

Learn MoreValue-added services that enhance product quality, functionality, and delivery efficiency.

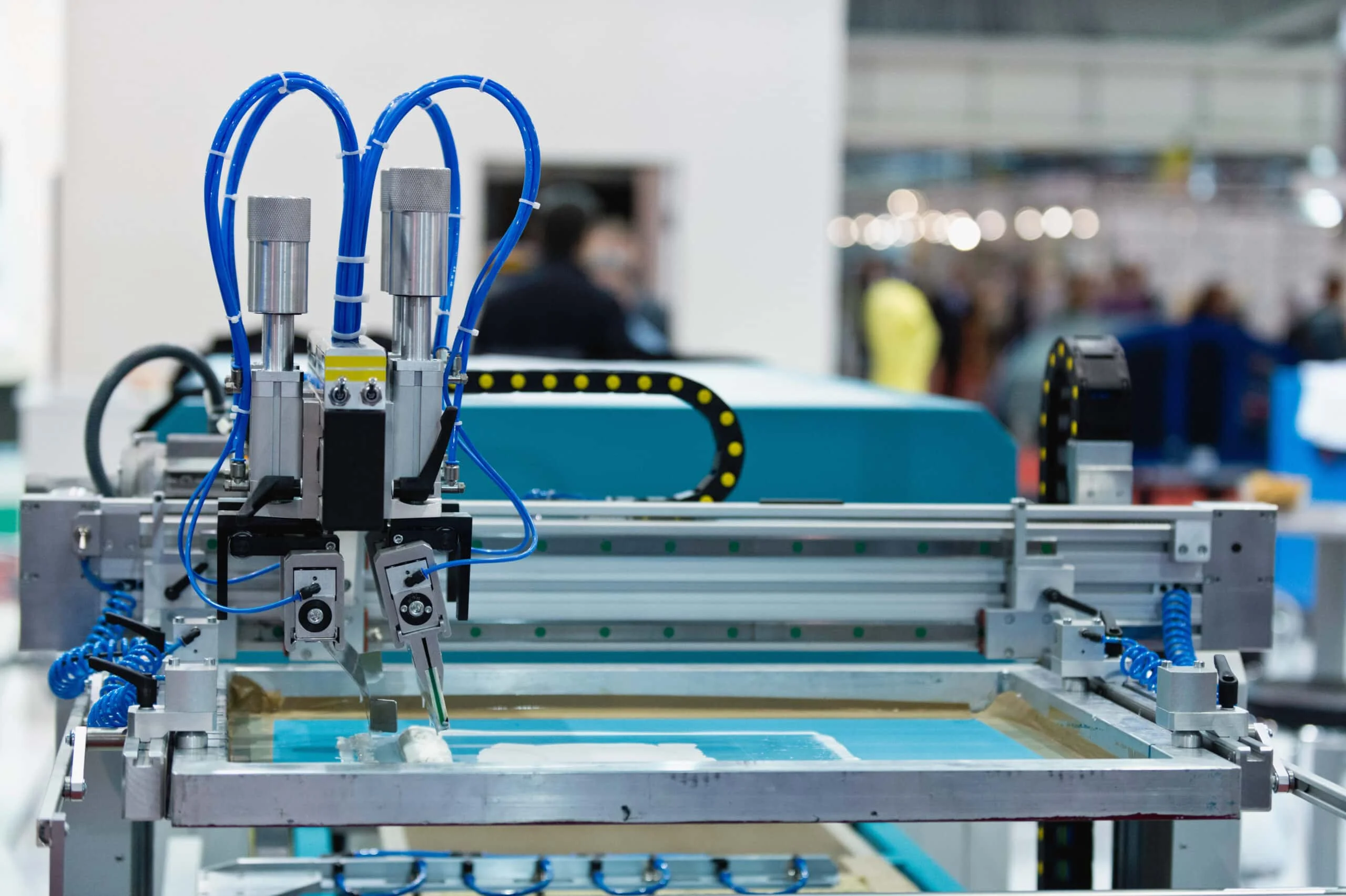

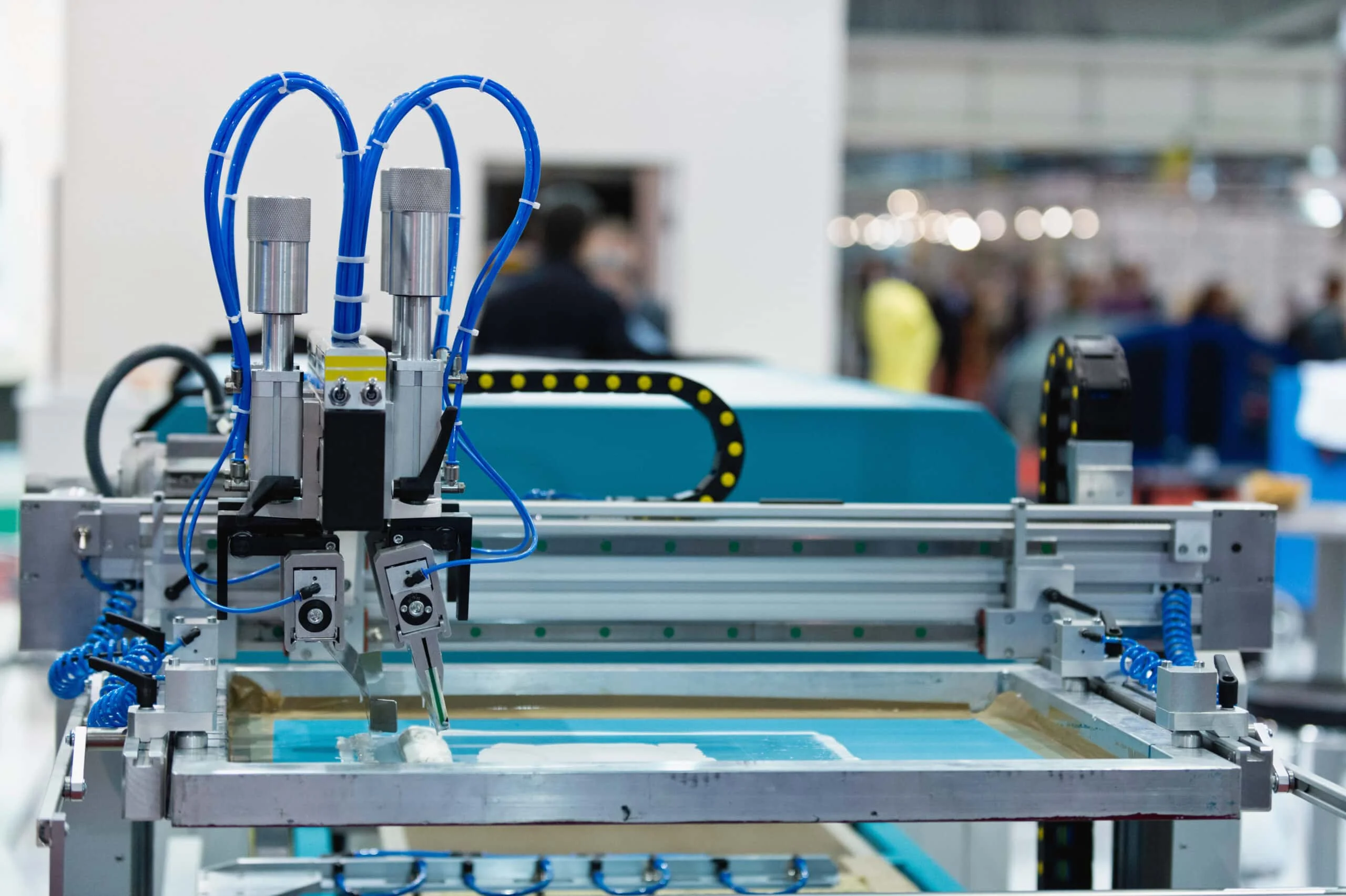

Automated pad printing, labeling, ultrasonic welding, and final assembly integrated into production cells.

End-to-end oversight from concept to commercialization with dedicated project engineers.

ISO Class 7 and 8 cleanrooms for medical device and pharmaceutical manufacturing.

Continuous improvement through automation, lean manufacturing, and employee engagement.

Specialized facilities and engineering teams dedicated to healthcare and pharmaceutical manufacturing.

ISO-certified and FDA-registered facilities with rigorous quality control systems ensuring compliance and exceeding customer expectations.

One-stop manufacturing partner with integrated services from design to delivery, reducing supply chain complexity.

Established in 1980, Plastikon brings decades of expertise in plastic manufacturing for regulated industries.

High-performance plastic components and systems for critical applications.

Precision-molded enclosures for diagnostic and monitoring devices with EMI shielding options.

Components for auto-injectors, inhalers, and wearable drug delivery systems.

Custom thermoformed trays for sterile instrument packaging and organization.

Blister packs, vials, and B/F/S containers for sterile liquid medications.

Integrated plastic components for rapid testing and point-of-care diagnostics.

High-precision steel and aluminum molds with quick turnaround and lifetime support.

Multi-material parts with soft-touch grips, seals, and integrated gaskets.

Final assembly and packaging in ISO-certified cleanroom environments.

For quotes, technical inquiries, or partnership opportunities, visit our official website to get in touch with our team.

Visit Official WebsitePhone: 888-538-9374

Location: Lawrence, Kansas, USA

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info