About PINGLE Machinery

A trusted leader in grain processing equipment since 1991, delivering innovation, quality, and turn-key solutions globally.

Pingle Group: Engineering Excellence Since 1991

Pingle Group is a globally recognized supplier of grain machinery, integrating research & development, design, production, installation, and commissioning. We specialize in complete sets of grain processing equipment and deliver full turn-key projects including steel structure buildings and silos.

Our mission is to provide integrated solutions for fine grain processing, combining advanced technology with reliable performance. With decades of experience, we serve clients across Africa, Asia, South America, and Eastern Europe.

- Turn-key project execution

- R&D-driven innovation

- Global installation & support

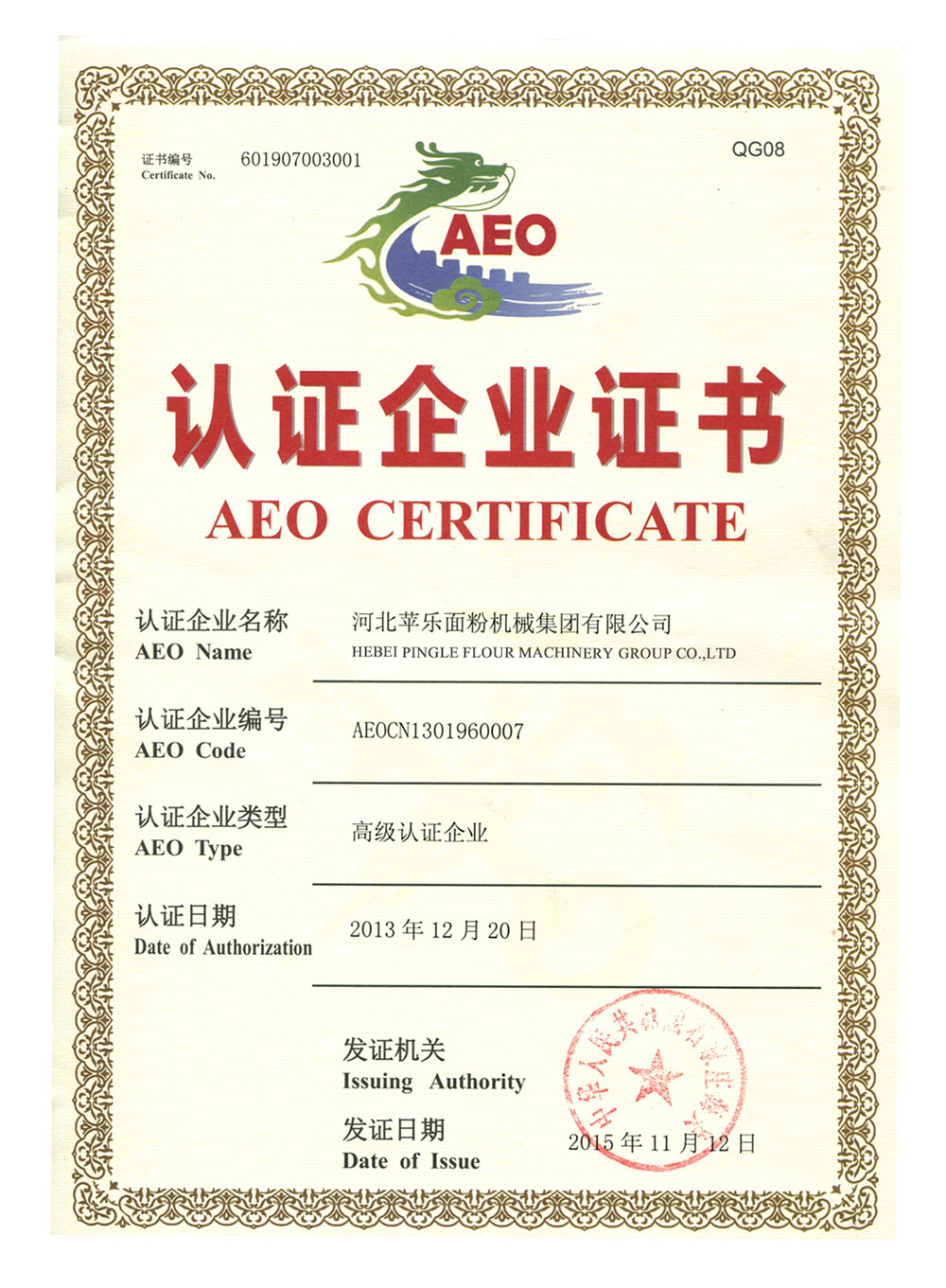

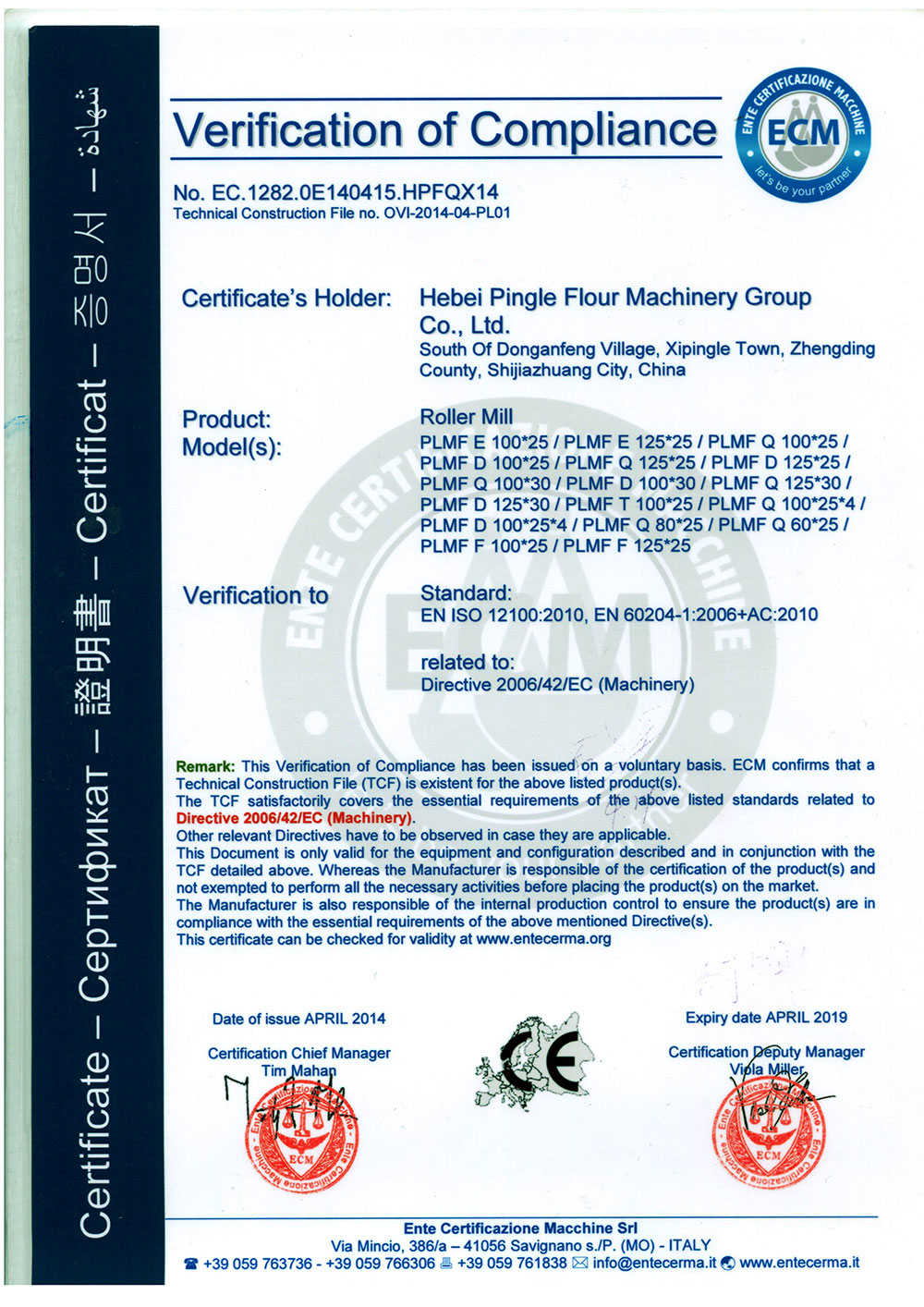

- ISO-certified manufacturing