Premium Tool & Mold Steel Solutions

RansenSteel delivers high-performance Hot Work, Cold Work, Plastic Mold, and High Speed Tool Steels with precision engineering and global reliability.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

RansenSteel delivers high-performance Hot Work, Cold Work, Plastic Mold, and High Speed Tool Steels with precision engineering and global reliability.

Ransen Metal Materials & Shenzhen Ransen Special Steel Co., Ltd is a leading special steel enterprise specializing in the production, sales, and R&D of high-quality mold steel. With our manufacturing base in Huangshi City, Hubei Province, and international trading operations in Shenzhen, Guangdong Province, we deliver precision-engineered steel solutions to global markets.

Our facility features energy-saving, high-precision mold module and forging production lines, supported by dedicated raw material, mold, and processing workshops, along with a state-of-the-art technical center ensuring consistent product excellence.

Years of Industry Experience

Global Clients Served

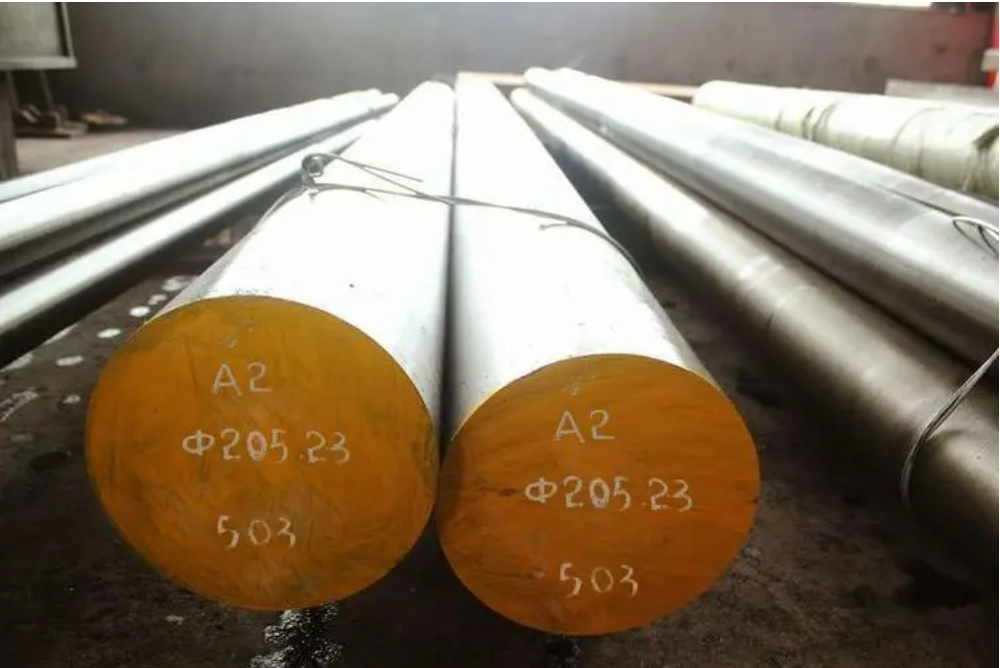

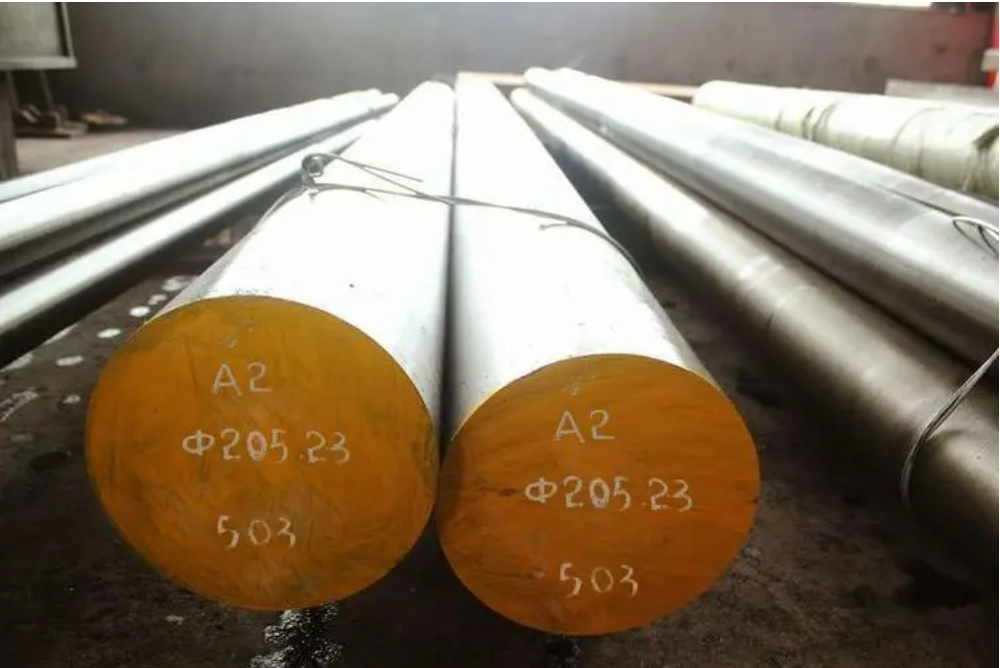

Discover our comprehensive range of high-performance tool and mold steels, engineered for durability, precision, and thermal stability across industrial applications.

Excellent thermal fatigue resistance and toughness for die casting and forging applications.

Hot Work Steel

High vanadium content for superior wear resistance and thermal stability in high-stress environments.

Hot Work Steel

High carbon-chromium alloy with excellent wear resistance and dimensional stability.

Cold Work Steel

High-carbon, high-chromium steel ideal for cutting, blanking, and forming tools.

Cold Work Steel

Tungsten-molybdenum high-speed steel with excellent red hardness and wear resistance.

High Speed Steel

Pre-hardened steel with excellent polishability and corrosion resistance for plastic molds.

Plastic Mold Steel

High toughness and thermal shock resistance for forging and extrusion dies.

Hot Work Steel

High-carbon, high-chromium steel with superior wear resistance and edge retention.

Cold Work Steel

Low-alloy cold work steel with good machinability and moderate wear resistance.

Cold Work Steel

Shock-resisting steel with high impact toughness and moderate wear resistance.

Cold Work Steel

High thermal conductivity and fatigue resistance for aluminum and zinc die casting.

Hot Work Steel

Corrosion-resistant steel with excellent polishability for PVC and acidic environments.

Plastic Mold SteelWe combine advanced manufacturing, rigorous quality control, and customer-focused service to deliver unmatched steel solutions.

ISO-certified production with strict quality control at every stage.

Efficient logistics network ensures timely global delivery.

Dedicated team available to assist with technical and commercial needs.

In-house R&D and technical center for continuous innovation.

Hot work tool steel is designed to withstand high temperatures and thermal cycling, making it ideal for die casting, forging, and extrusion applications where tools are exposed to repeated heating and cooling.

Cold work tool steel is used for cutting, stamping, and forming operations at low temperatures. It offers high hardness, wear resistance, and dimensional stability under mechanical stress.

Plastic mold steel is engineered for injection molding applications, offering excellent polishability, corrosion resistance, and thermal conductivity to ensure high-quality plastic part production.

Yes, RansenSteel provides customized steel grades and processing services based on specific customer requirements and application needs.

Standard delivery times range from 7 to 15 days depending on destination and order size. We offer expedited shipping options upon request.

For inquiries, pricing, or technical support, reach out to our team. We respond within 12 hours.

Office: Room 306, Guangshen Building, 3rd Floor, No. 2023, Shennan East Road, Nanhu Street, Luohu District, Shenzhen

Email: david@ransensteel.com

Phone: +86-769-21665876

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info