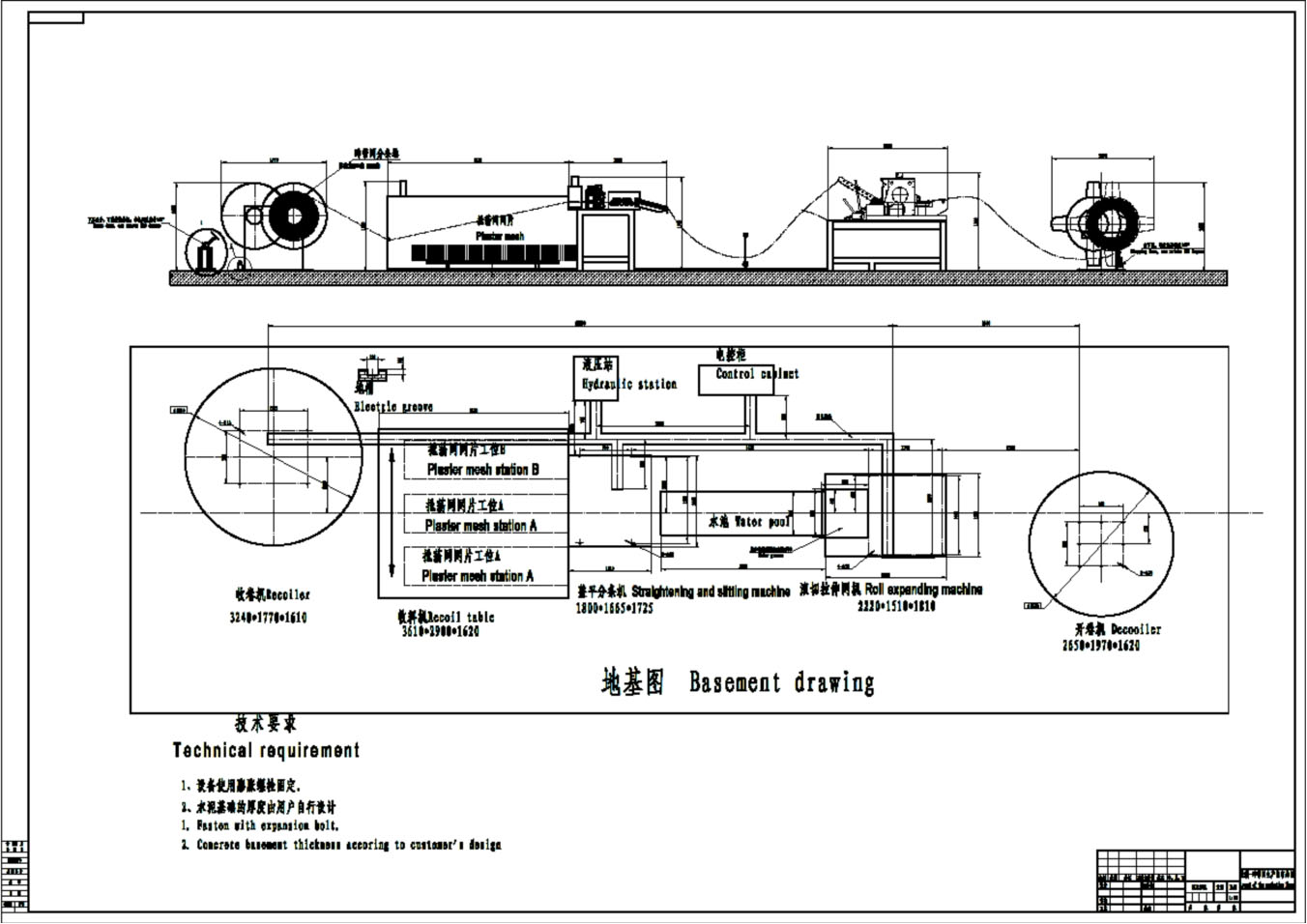

Engineered for Global Construction Standards

Wuxi Anber Machine Co., Ltd. (ABO Building Materials (Kunshan) Co., Ltd.) is a leading manufacturer of metal lath and plaster reinforcement machinery. With decades of engineering expertise, we deliver high-speed, automated production lines trusted by manufacturers across Asia, Europe, and North America.

Our machines are designed for precision, durability, and compliance with international standards. From rib lath and hi-rib systems to corner beads and plaster stops, every product is built to enhance structural integrity in modern construction.