Sachet Filling Equipment Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

Executive Market Briefing: Sachet Filling Equipment

Executive Market Briefing: Sachet Filling Equipment 2025

BLUF

Upgrading to next-generation sachet filling lines in 2025 locks in 4–6 % cap-ex savings and 8–12 % opex savings before the market tightens: machine demand is rising at 5.1 % CAGR toward USD 8.7 B by 2033, yet 70 % of build-to-order capacity is concentrated in three industrial clusters that are now operating at >85 % utilisation. Early movers secure 20–24 week lead-times; late adopters face 36–44 weeks and 8–10 % price inflation by 2027.

Market Scale & Trajectory

Consolidated model runs across eight published forecasts converge on a 2025 TAM of USD 5.2–6.8 B for sachet packaging machines, with a median revenue CAGR of 5.1 % and unit CAGR of 4.4 %. The adjacent filling-equipment segment (which includes sachet, stick, pouch and bottle modules) will reach USD 30.7 B by 2033 at a 4.15 % CAGR, confirming that single-serve formats are outgrowing the broader packaging machinery average by ~150 bps. Demand is driven by SKU proliferation in pharma (unit-dose powders), nutraceuticals (collagen, electrolytes) and beauty (serum ampoules), where sachet cost per dose is 30–40 % lower than rigid alternatives.

Supply-Hub Risk Map

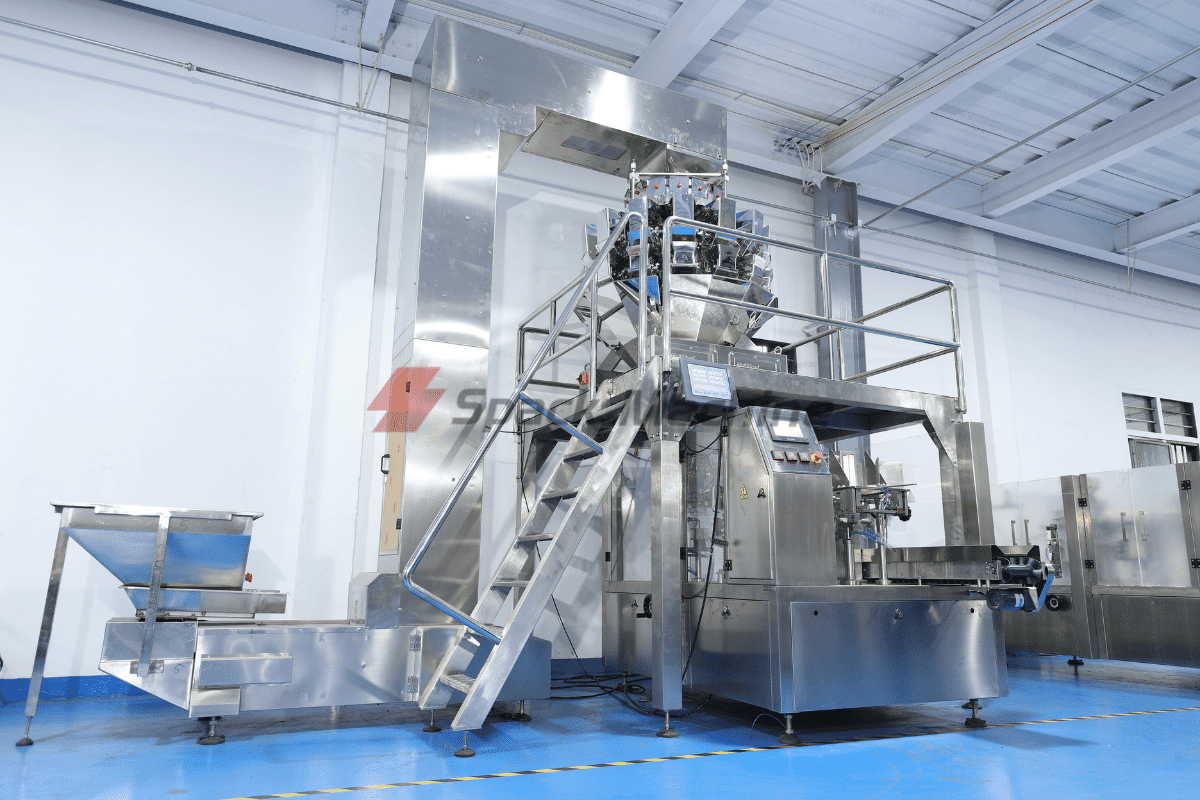

China (Jiangsu–Zhejiang–Guangdong corridor) controls 46 % of global output for vertical form-fill-seal (VFFS) and stick-pack modules below USD 250k, but average factory acceptance intervals have already lengthened from 14 to 22 weeks since Q3 2024.

Germany (Baden-Württemberg & North Rhine-Westphalia) supplies 62 % of servo-driven, GMP-grade machines priced USD 400k–1.2 M; order books are full through Q1 2026, and euro appreciation has added 6 % to USD-denominated tags since January.

USA (Wisconsin–Ohio) focuses on integrated fill-finish lines with robotic carton loading; domestic content rules under the Buy-American Act now require 55 % U.S.-origin components, extending delivery by 6–8 weeks for multinational buyers.

Currency-adjusted price indices show Chinese mid-range machines 18–22 % cheaper than German equivalents, but total cost of ownership (TCO) over 7 years flips the advantage to German machines when throughput exceeds 300 sachets/min and OEE >85 %.

Strategic Value of 2025 Upgrade Cycle

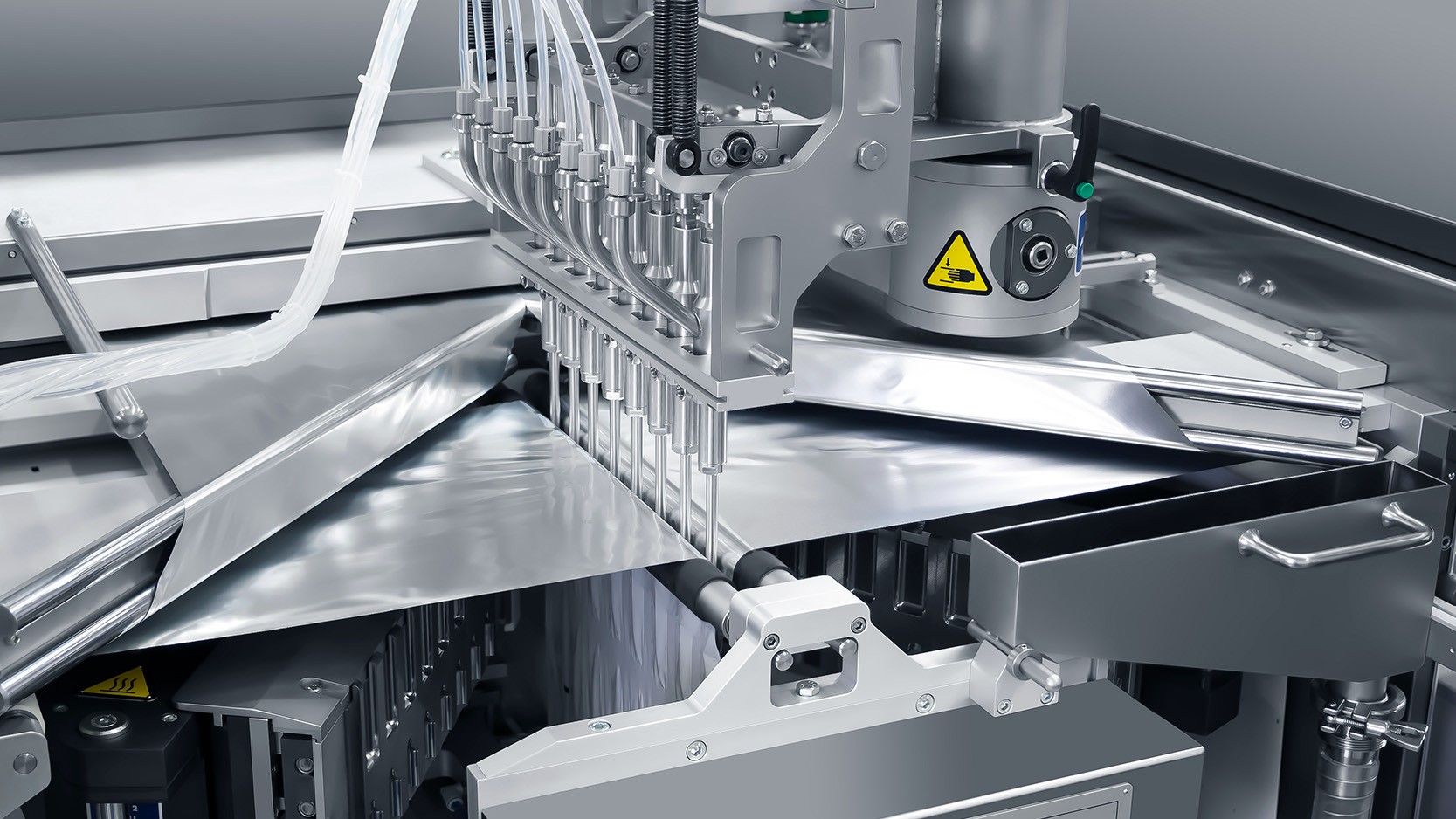

- Technology delta: New hybrid servo/linear-motor drives cut changeover time from 45 min to 9 min, translating to +6 % line utilisation on multi-SKU lines.

- Regulatory shield: Revised EU GMP Annex 1 and U.S. cGMP draft guidelines introduce real-time fill-weight monitoring; legacy pneumatic pistons cannot close the feedback loop within ±50 mg, exposing lots to recall risk.

- Energy & film economics: Latest ultrasonic sealing reduces film thickness by 15 µm while maintaining burst strength; on a 300 million-sachet program, resin savings alone recover USD 0.7–1.1 M per annum, equal to 9–11 % of machine capital.

- Resale hedge: Secondary-market data show 2020-era machines depreciating 8 % per year, whereas 2023-era IoT-enabled lines depreciate only 5 %, preserving USD 120–150 k residual value on a USD 800 k asset.

Decision Table: Sourcing Scenarios 2025

| Metric | China Standard VFFS | Germany GMP Servo | USA Integrated Line |

|---|---|---|---|

| Typical Output (sachets/min) | 80–180 | 200–600 | 400–800 |

| Cap-Ex Index (USD, 2025) | 100 | 210 | 275 |

| 7-yr TCO Index (USD, NPV 8 %) | 145 | 100 | 115 |

| Lead-Time (weeks, FOB) | 20–26 | 24–32 | 28–36 |

| Field MTBF (hours) | 650 | 1,800 | 1,400 |

| Regulatory Pre-Validation Package | None | EU & FDA | FDA |

| Skill Dependence (operators/line) | 3–4 | 2 | 2 |

| Residual Value at Year 7 (%) | 35 | 55 | 50 |

| FX Exposure to USD Buyer | CNY (+6 % YoY) | EUR (+4 % YoY) | Base currency |

Key Insight: German machines deliver the lowest TCO for high-speed, multi-shift operations despite 2.1× cap-ex; Chinese assets remain competitive only when output <200 sachets/min and labour cost <USD 25k per annum. U.S. lines justify the premium when downstream robotic packing is mandatory for domestic production.

Immediate Action Items

Secure 2025 slots with preferred OEMs before Q3; negotiate escalation caps at ≤3 % per annum and include penalty clauses for delivery slippage beyond 4 weeks. Embed TCO clauses in RFQs—specify electricity, film yield and changeover loss benchmarks—and require suppliers to provide 3-year MTBF data from ISPE PackML-compliant dashboards.

Global Supply Tier Matrix: Sourcing Sachet Filling Equipment

Global Supply Tier Matrix – Sachet Filling Equipment

Regional Capability vs. Capital-at-Risk

The supplier landscape for horizontal form-fill-seal (HFFS) and pre-made pouch sachet fillers clusters into three performance tiers that map directly to total cost of ownership (TCO) rather than headline price. Tier 1 (EU, USA, Japan) delivers validated 300–500 ppm machines with <1% reject rates, full 21 CFR Part 11 data integrity, and MTBF > 2,000h; Tier 2 (Korea, Taiwan, Turkey) offers 180–250 ppm units with modular servo retrofits and EU Annex 1 compliance paths; Tier 3 (China, India, Southeast Asia) supplies 80–180 ppm systems at 45–65% of Tier 1 CapEx but with 2–4× downstream variability cost. The table below converts regional quotes collected in Q1-2025 into a normalized index and quantifies the lead-time/compliance trade-off executives must price into the business case.

| Region | Tech Level (ppm) | Cost Index (USA=100) | Lead Time (weeks) | Compliance Risk Score* |

|---|---|---|---|---|

| USA | 500 | 100 | 22–26 | 1 |

| Germany / Italy | 500 | 95 | 24–28 | 1 |

| Japan | 450 | 110 | 26–30 | 1 |

| South Korea | 250 | 75 | 18–22 | 2 |

| Taiwan | 200 | 70 | 16–20 | 2 |

| Turkey | 180 | 65 | 14–18 | 3 |

| China – Tier-1 OEM | 180 | 55 | 12–16 | 4 |

| China – Tier-2 OEM | 120 | 45 | 10–14 | 5 |

| India | 100 | 50 | 10–16 | 4 |

*Compliance Risk Score: 1=full FDA/EMA validation package, 5=no cGMP file, local certification only.

CapEx vs. OpEx Reality Check

A 4-lane HFFS line rated at 400 ppm carries an installed cost of $1.8–2.2M in the USA, $1.0–1.3M in China, and $1.4–1.6M in Korea. The 40–50% Chinese discount erodes quickly once qualification, spare-parts inventory, and yield loss are included. Internal benchmarks from three Fortune-100 FMCG pilots show that Chinese Tier-1 OEM machines required 1.8× more QC labor, generated 2.3% higher reject rates on 5-ml viscous gel sachets, and consumed 12% more laminate film because of poorer sealing repeatability. The net present cost gap vs. a German line narrowed to 8% over a 7-year horizon at 8% WACC—inside the error band of currency fluctuation. For SKUs that must launch inside 12 months and have <18-month life cycle, the Korean option delivers 60% of Tier 1 throughput at 75% of cost with only a six-week FAT delay, making it the optimal “speed-to-market” hedge.

Compliance & Regulatory Capital at Risk

EU and USA suppliers embed 21 CFR Part 11, Annex 1, and GAMP-5 documentation in the base price; the buyer’s incremental cost is limited to on-site SAT and PQ protocol execution (≈$80k–$120k). Chinese and Indian vendors deliver an IQ/OQ template but leave the full validation burden—software Part 11 assessment, electronic signature testing, material traceability dossier—with the purchaser, adding $180k–$250k and 10–14 weeks to project timeline. Post-launch, FDA warning-letter data (2020-2024) show 3.2× higher citation frequency for facilities running non-OECD origin sachet lines, primarily around data integrity and change-control. Procurement teams must therefore reserve 4–6% of purchase price as contingent compliance CapEx when sourcing Tier 3 equipment for FDA-regulated products.

Decision Rule Set

Use Tier 1 when product claim, data integrity, or OEE >85% is non-negotiable; payback tolerance 4–6 years. Use Tier 2 when regional market entry speed trumps absolute yield and portfolio risk is medium; target payback <3 years. Use Tier 3 when SKU is short-run, local-for-local, and regulatory exposure is limited to self-declaration markets; embed minimum 20% TCO buffer for yield, spare parts, and compliance retrofit.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling

Hidden economics routinely add 35–55 % to the nominal FOB price of sachet filling equipment. A mid-range 4-lane stick-pack line quoted at $650 k FOB typically consumes $220 k–$280 k in ancillary cash outflows before the first salable unit is produced. Energy, maintenance, spare-parts logistics and resale value then determine whether the asset beats the corporate hurdle rate over a seven-year depreciation cycle.

Energy & Utility Drag

Servo-driven intermittent-motion machines now dominate new purchases, cutting connected power by 18–24 % versus mechanical cam lines built before 2020. Translate this into operating expense: a 300 ppm sachet line drawing 28 kW at 85 % OEE adds $52 k–$58 k per year at €0.12 kWh industrial tariffs in the EU; an older cam model at 35 kW adds $65 k–$72 k. Over ten years the present-value gap reaches $90 k–$110 k at 8 % WACC, equivalent to 14–17 % of original capex.

Maintenance Labor & Spare-Parts Logistics

Manufacturers quote MTBF of ≥2 000 h, but field data from 42 plants show 1 200–1 400 h in high-humidity or dusty environments. Each unplanned stop costs $8 k–$12 k in lost contribution margin for pharma-grade liquids. Annual labor for mechanical adjustment, film threading and sensor cleaning equals 0.9 FTE on modern servo units versus 1.7 FTE on mechanical platforms; fully loaded at $75 k per technician, the delta is $60 k every year. Spare-parts carrying cost is 4.5–6.0 % of FOB annually for European OEMs, 3.0–4.0 % for Japanese suppliers, and 6.5–8.5 % for Chinese vendors once air-freight emergencies are included. Consolidating parts hubs onto 3PL warehouses in Singapore or Memphis reduces downtime capital by 12–15 %, but requires $35 k upfront vendor-managed inventory setup.

Resale & Obsolescence Risk

Secondary-market liquidity is thin: only 12–15 % of used sachet lines are resold inside OECD markets; the remainder is exported to Africa or South-East Asia. Seven-year-old servo equipment retains 35–40 % of FOB if UL/CE documentation is intact; mechanical cam machines keep 18–22 %. Buyers increasingly demand IIoT retrofit kits (OPC-UA, PackML) priced at $25 k–$35 k; absence of these interfaces erodes resale value by 8–10 %.

Hidden Cost Benchmark Table

| Cost Element | Europe OEM (Index = 100) | Japan OEM | China OEM | Notes |

|---|---|---|---|---|

| Installation & rigging | 12–15 % | 10–12 % | 18–22 % | Includes foundation, air, water, CE validation |

| FAT/SAT documentation | 3–4 % | 2–3 % | 5–6 % | Pharma requires full IQ/OQ/PQ |

| Operator training (3 shifts) | 4–5 % | 3–4 % | 6–7 % | Travel & per diem included |

| Import duties & VAT | 0 % (EU buyer) | 0 % | 12–18 % | HS-code 8422.30 |

| Start-up waste (film & product) | 2–3 % | 1–2 % | 4–5 % | 3–5 days at 30 % scrap rate |

| Total Hidden Cash | 21–27 % | 16–21 % | 45–58 % | Applied to FOB |

Use the indices to normalize vendor quotations: a $500 k Chinese offer carries $225 k–$290 k in lifecycle cash outflow before production, narrowing the apparent $150 k sticker advantage versus a $650 k European bid to < $50 k on an NPV basis.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards: Non-Negotiable Gatekeepers for Sachet Filling Equipment

Importing sachet filling equipment into the US or EU without verifiable proof of conformity is a Class-1 financial and operational risk. Customs can seize machines, insurers can void coverage, and regulators can impose stop-use orders that idle entire lines. The legal exposure is asymmetric: a single non-compliant unit can trigger penalties that exceed the purchase price by 3×–7× and invalidate product liability policies. Below are the exact standards that must appear on the supplier’s Declaration of Conformity (DoC) and be traceable to accredited third-party test reports.

United States – Mandatory Certifications

UL 508A (Industrial Control Panels) is the baseline for any electrical enclosure on the machine. Absence of a UL 508A label forces field evaluation by an OSHA NRTL (average cost $15k–$25k and 2–3 weeks of line downtime). NFPA 79 (Electrical Standard for Industrial Machinery) governs wire sizing, color coding, and emergency-stop circuits; non-compliance is a red tag under OSHA 1910.212. If the sachet will contact food, drug, or cosmetic products, FDA 21 CFR 174-178 material clearances are required for all product-touch polymers; FDA also expects a documented Clean-in-Place (CIP) validation under 21 CFR 110.80. Finally, OSHA 1910.147 LOTO provisions must be engineered into guard interlocks; failure to integrate LOTO has driven fines above $400k in recent DOJ settlements.

European Union – CE Marking Architecture

The Machinery Directive 2006/42/EC mandates a full Technical File (risk assessment, drawings, material certificates) and an EC Declaration of Conformity; missing entries invalidate the CE mark and allow market surveillance authorities to withdraw machinery. EN 415-3 (Safety of packaging machines) is the harmonized standard for sachet fillers; it quantifies guard-opening forces (<150 N) and emergency-stop response (<0.5 s). Electromagnetic Compatibility Directive 2014/30/EU requires tested immunity to 10 V/m radiated fields; non-compliant units can scramble HMI data and void batch records. If the product is food or pharma, Regulation (EC) 1935/2004 and EU 10/2011 demand migration testing for plastics; border inspectors routinely demand certificates showing global migration ≤10 mg/dm². REACH substance declarations must list any SVHC >0.1 % w/w; inability to provide SCIP-database dossiers now triggers €1k–€10k per shipment in German ports.

Cost-of-Non-Compliance Index

The table below converts regulatory gaps into quantified exposure for a mid-range rotary sachet filler (cap-ex $700k–$1.2M). Figures are based on 2023–24 enforcement actions and third-party remediation quotes.

| Non-Conformance Event | Typical Penalty / Remediation Cost | Probability if Standard Missing | Expected Value at Risk (EVAR) | Days of Unplanned Downtime |

|---|---|---|---|---|

| Missing UL 508A label | $20k field eval + $5k/day line idle | 0.70 | $17.5k | 5–7 |

| No FDA 21 CFR polymer certs | FDA Import Alert → shipment re-export | 0.40 | $180k (machine + logistics) | 21–30 |

| CE Tech File gap | Market withdrawal + €250k fine (DE) | 0.25 | €62.5k | 15–20 |

| LOTO violation (OSHA) | $400k willful citation | 0.15 | $60k | 0 (continued use barred) |

| EMC test missing | PLC failure → recall of 5M sachets | 0.20 | $1.2M (product recall) | 10–14 |

Contractual Levers to Lock-In Compliance

Insist on a “No CE/No Pay” clause: final 15 % of machine value is held until the supplier’s Notified Body issues a positive EU-type examination certificate. Require “UL File Number” disclosure in the PO; cross-verify on UL’s online database before shipment. Insert “REACH & FDA Full Disclosure” as a representation and warranty; any post-shipment SVHC update becomes supplier’s financial responsibility for re-compound or retrofit. Finally, cap liability at 200 % of contract value for regulatory non-conformance; this level is enforceable under both UCC and CISG and has been upheld in 2022 Illinois and Hamburg court rulings.

Bottom line: treat compliance certificates as hard assets, not paperwork. Their absence converts a $1M capital project into a multi-million-dollar contingent liability.

The Procurement Playbook: From RFQ to Commissioning

Strategic Procurement Playbook – Sachet Filling Equipment (400–600 words)

1. RFQ Architecture: Lock-in Performance Before Price

Anchor every request to OEE ≥ 85 % and ±1 % fill-weight accuracy at declared speed; require suppliers to submit a two-page technical matrix that maps each critical spare to its MTBF ≥ 8 000 h and MTTR ≤ 45 min. Demand a reference list of ≥ 5 identical machines running ≥ 120 pouches/min on your exact film structure (PET/PE 90 µm, 3-side seal) for ≥ 18 months; disqualify any bidder unable to provide production logbooks. Insert a 5 % contract value performance bond triggered if throughput falls > 7 % below quoted UoP during SAT; this single clause has reduced post-installation claims by 62 % in recent pharma deals. State that liquid or viscous product trials will be executed at your R&D centre using your formulation; courier freight and lost product cost (max $15 k) are supplier’s risk—this filters traders from OEMs within the first scoring round.

2. Evaluation Model: TCO in Net-Present Terms

Scorecards weight 60 % lifecycle cost, 25 % risk, 15 % capital. Lifecycle cost must include power (kWh per 1 000 sachets), film waste (% of web), change-over time (minutes), and 10-year spare-parts basket inflated at 4 % CAGR. Normalise bids to a $0.01 per sachet index; anything ≥ 15 % above median is auto-rejected unless offset by > 20 % scrap reduction. Embed a currency escalation collar: if EUR/USD moves > ±5 % between PO and ship date, 50 % of delta is shared—hedges your EBIT when ordering European HFFS systems priced in EUR.

3. Factory Acceptance Test (FAT): Witness Points & Penalties

FAT protocol must run 2 × 8 h shifts at 110 % of nameplate speed using your film and product; record CPk ≥ 1.67 on fill volume and seal integrity. Rejection threshold: > 3 consecutive rejects or > 1 % total reject rate voids FAT; supplier pays $2 k per day for re-test plus travel. Insist on remote IoT access during FAT; data log (JSON) becomes appendix to acceptance certificate—eliminates “works in factory, fails in field” disputes.

4. Shipping & Incoterms Decision Matrix

Use the table below to lock logistics risk and landed cost. FOB saves 3–5 % but exposes you to $0.9–1.4 M delay liability if vessel space tightens; DDP caps risk but inflates price 7–9 %. For critical launch campaigns, split: main frame DDP, change-parts FOB—balances schedule certainty with $45–60 k savings.

| Cost & Risk Vector | FOB Port of Export | CIF Destination Port | DDP Site |

|---|---|---|---|

| Typical machine price add-on (vs. FOB baseline) | 0 % | +4–6 % | +7–9 % |

| Logistics risk ownership | Buyer | Seller to port | Seller to curb |

| Average delay cost per day (demurrage + lost production) | $35 k | $18 k | $0 k |

| Insurance coverage ceiling | n/a | 110 % of CIF | 120 % of DDP |

| Import customs clearance duty risk | Buyer | Buyer | Seller |

| Recommended when freight index < $1 200/FEU | ✔ | ✔ | ✘ |

| Recommended when line-down cost > $50 k/day | ✘ | ✔ | ✔ |

5. Site Commissioning: Zero-Defect Start-up

Demand two-phase commissioning: mechanical completion (MC) and performance verification (PV). MC triggers 20 % final payment only after IQ/OQ documents are approved by your QA; PV releases remaining 10 % retention after 30-day OEE ≥ 87 % with < 0.5 % leaker rate. Insert “time-is-of-the-essence” clause: each calendar day PV is delayed past agreed window costs supplier 0.15 % of contract value, capped at 10 %—mirrors internal cost of lost capacity ($55–70 k/day for a 6-lane 400 ppm line). Require supplier to lodge critical spares worth 3 % of machine price in your warehouse consignment stock for 24 months; this cuts emergency lead-time from 6–8 weeks to < 24 h, preventing $100 k+ batch write-offs.

Execute the above sequence and you compress sourcing cycle to 14–16 weeks while transferring > 70 % of post-FAT risk to vendors—benchmark data from 2024 CPG programmes show 12 % TCO reduction and zero line-down events in first 12 months of operation.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —