About SEM China

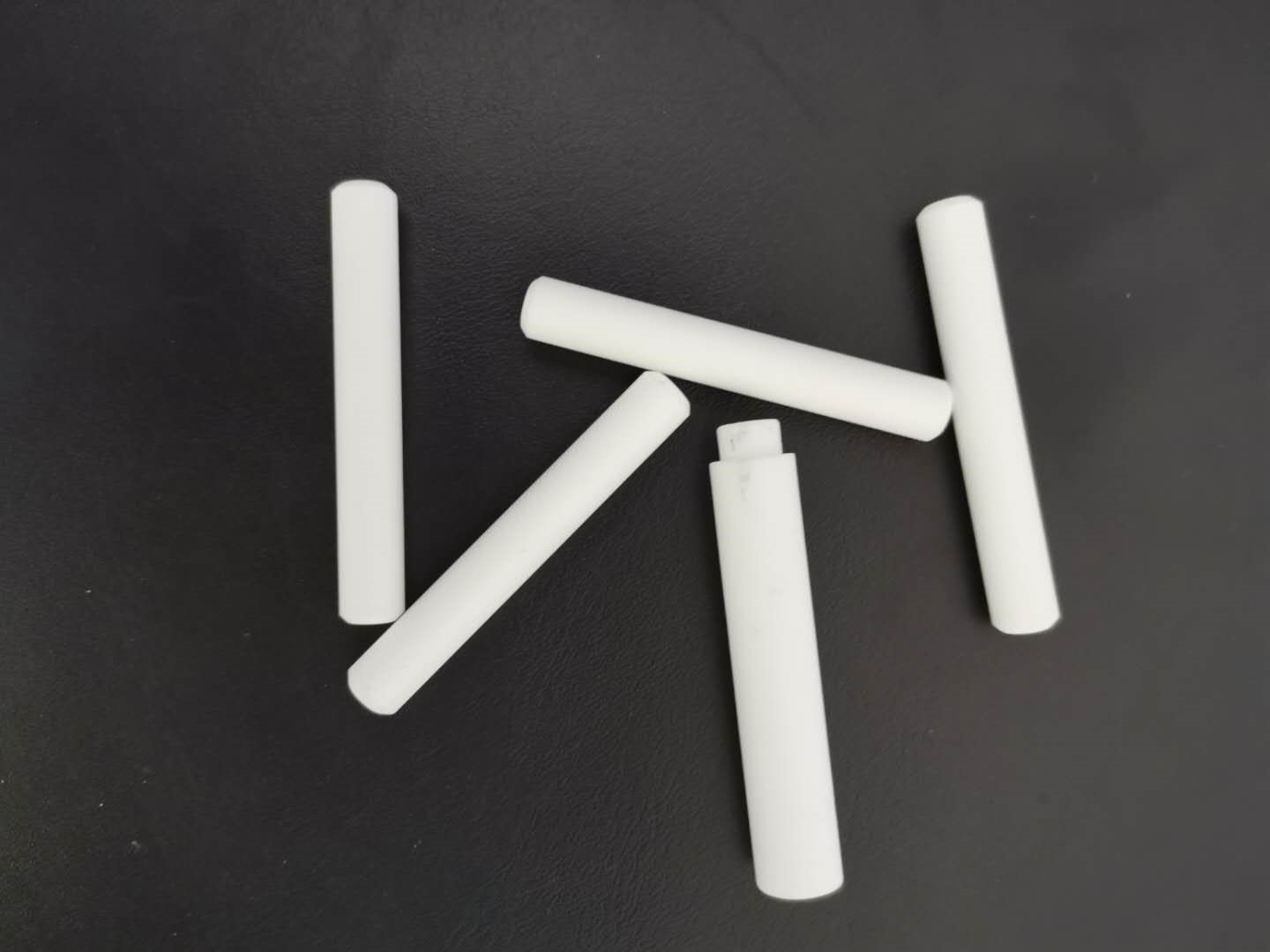

CHANGZHOU SEM MATIC CO., LTD (SEM China) specializes in the production of high-precision, high-performance ceramic structural parts and functional ceramic parts. With years of innovation and expertise, we deliver advanced ceramic solutions trusted across global industries.

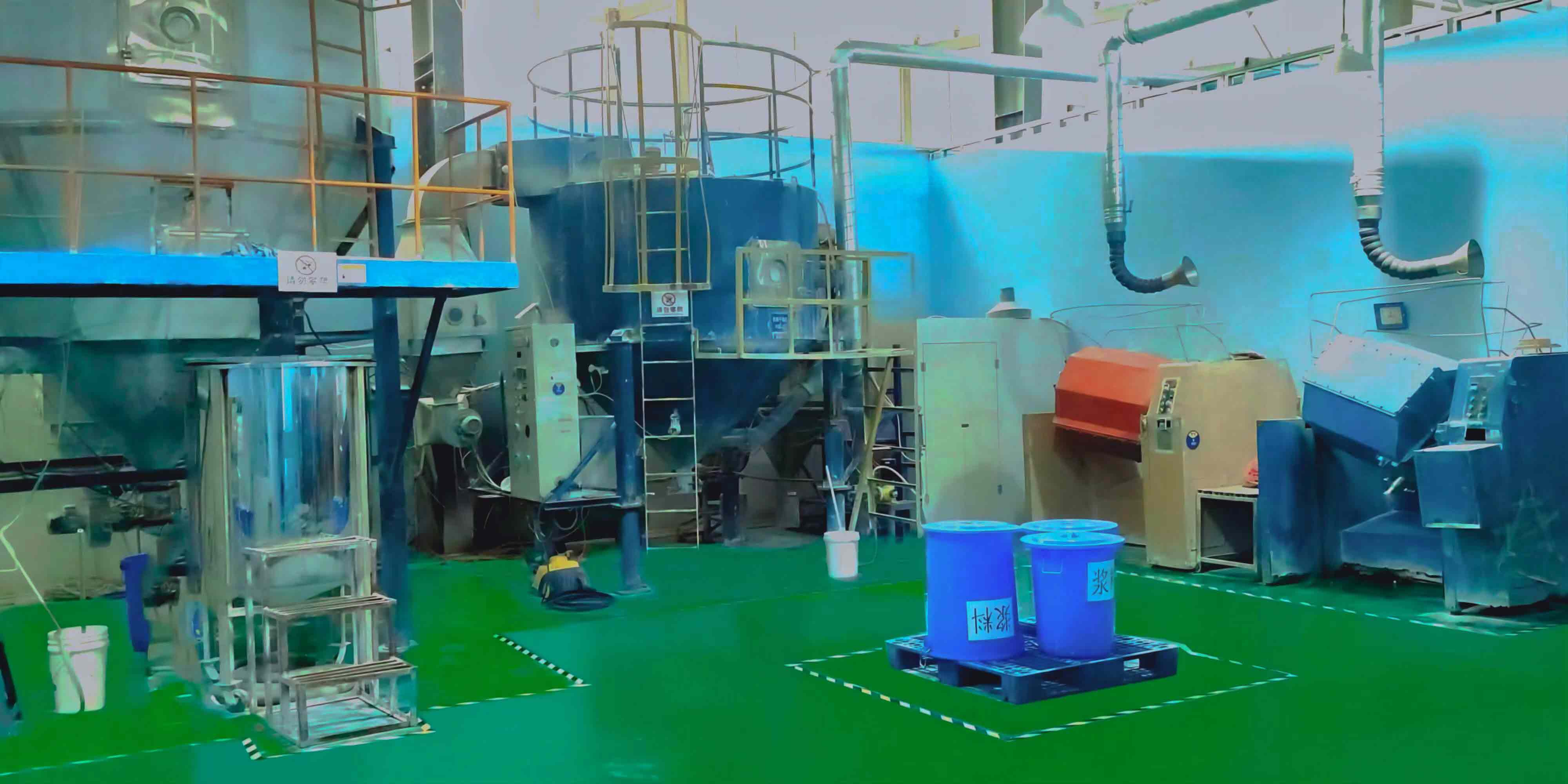

High-Quality Manufacturing

Advanced equipment and first-class management ensure consistent product quality and reliability.

Professional Technology

Dedicated technical team with independent R&D capabilities for custom ceramic solutions.

Customer-Centric Service

We support customers from R&D to mass production, continuously improving processes together.