About SG Mould Base

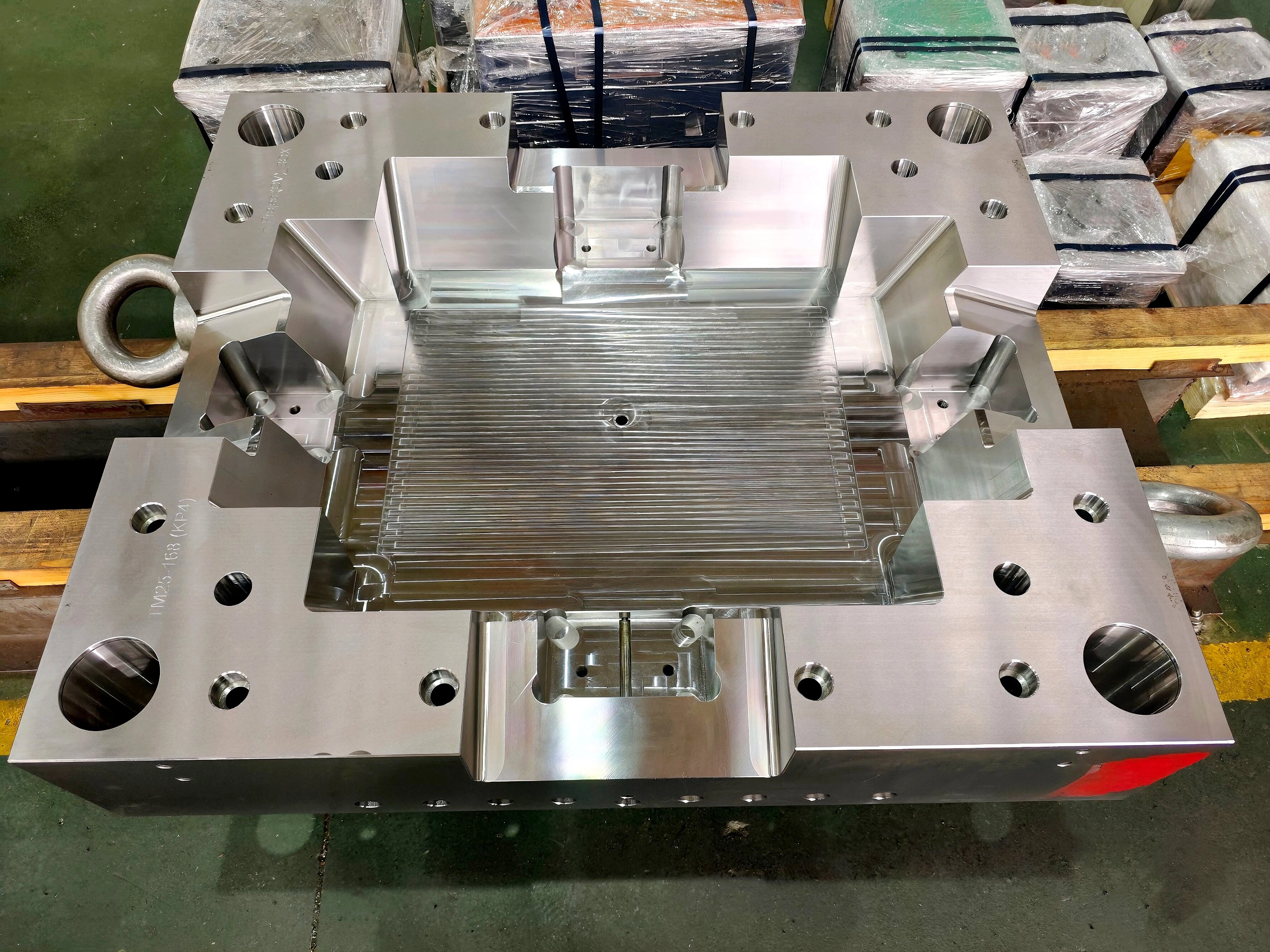

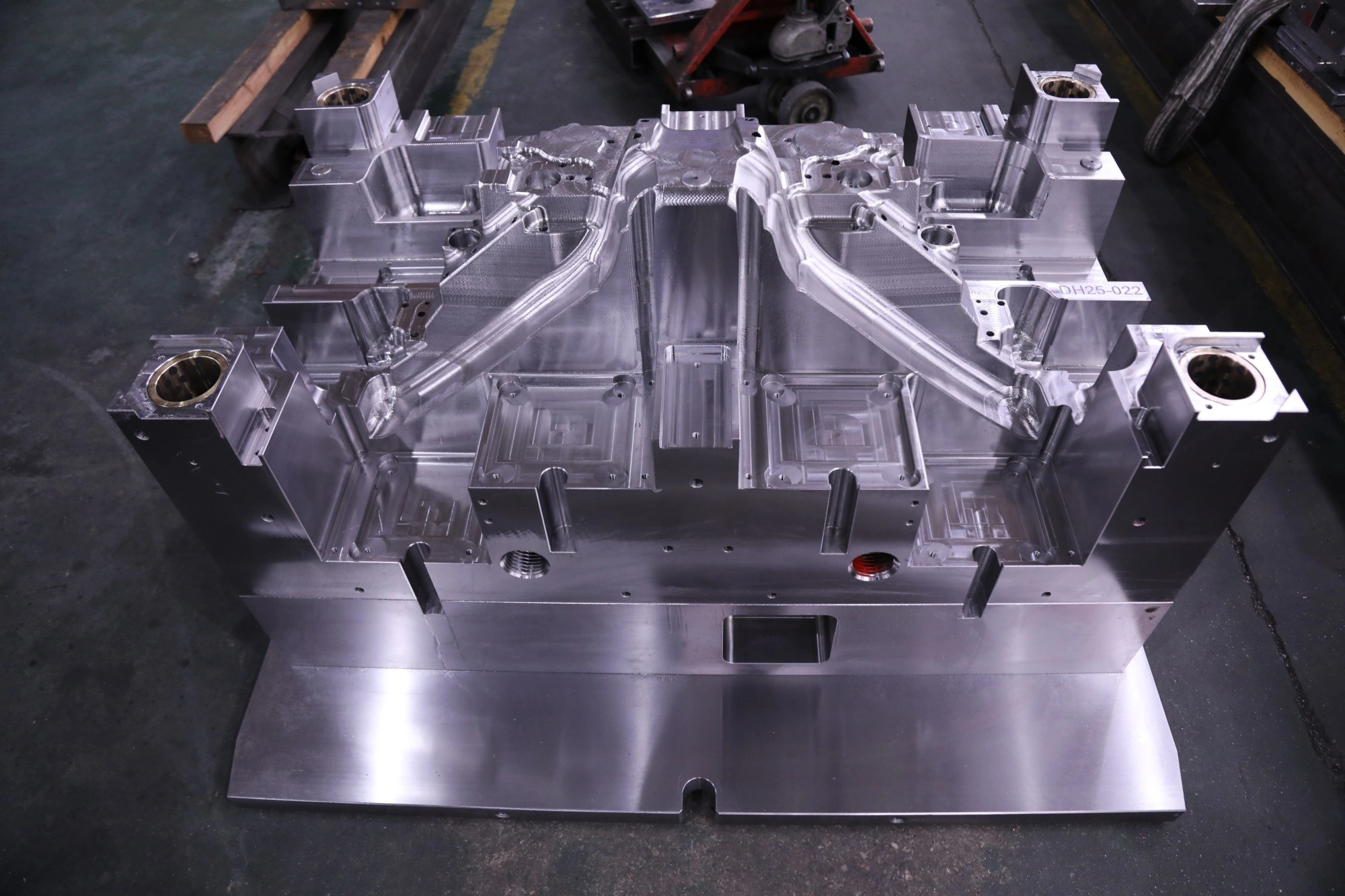

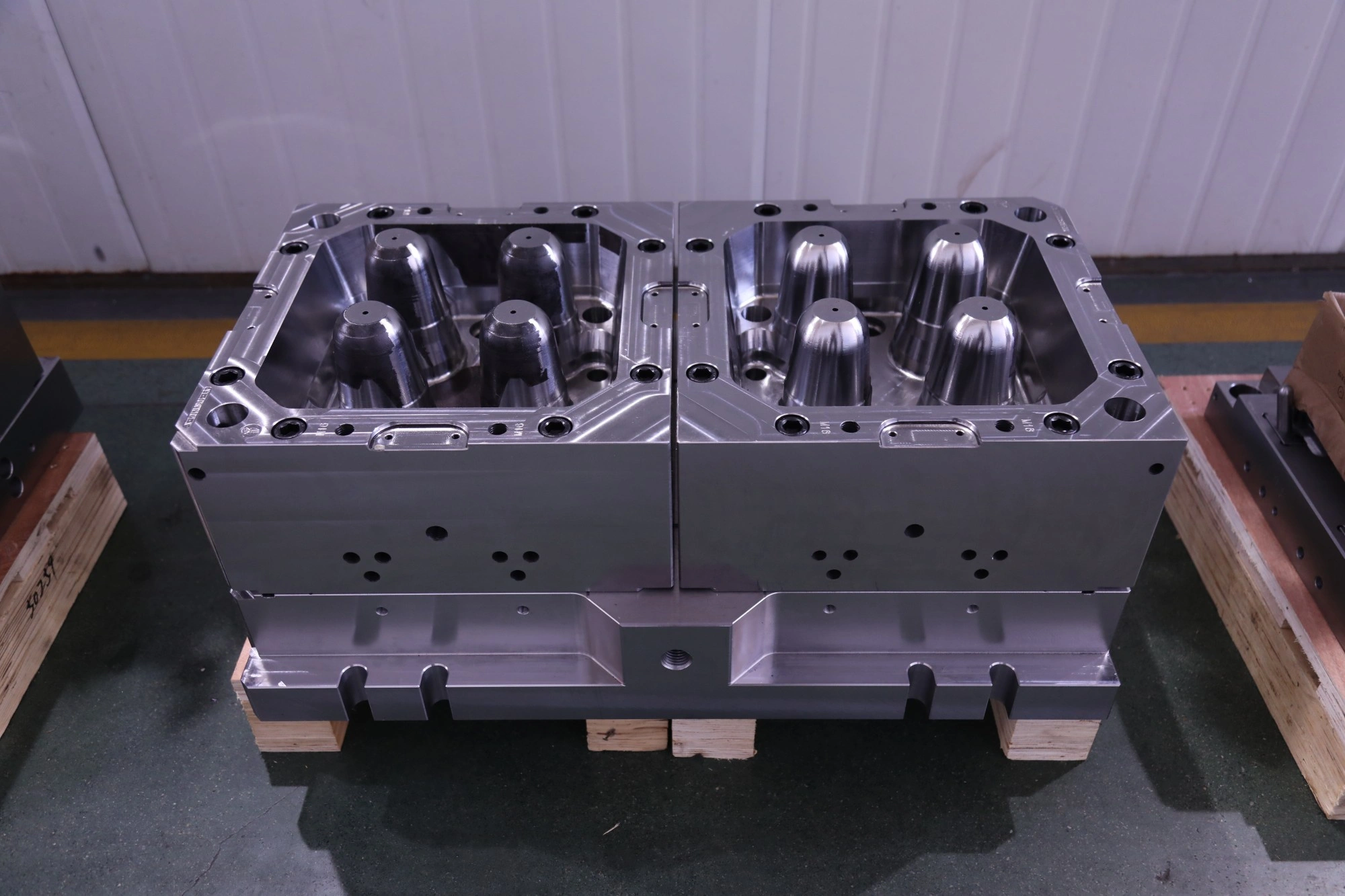

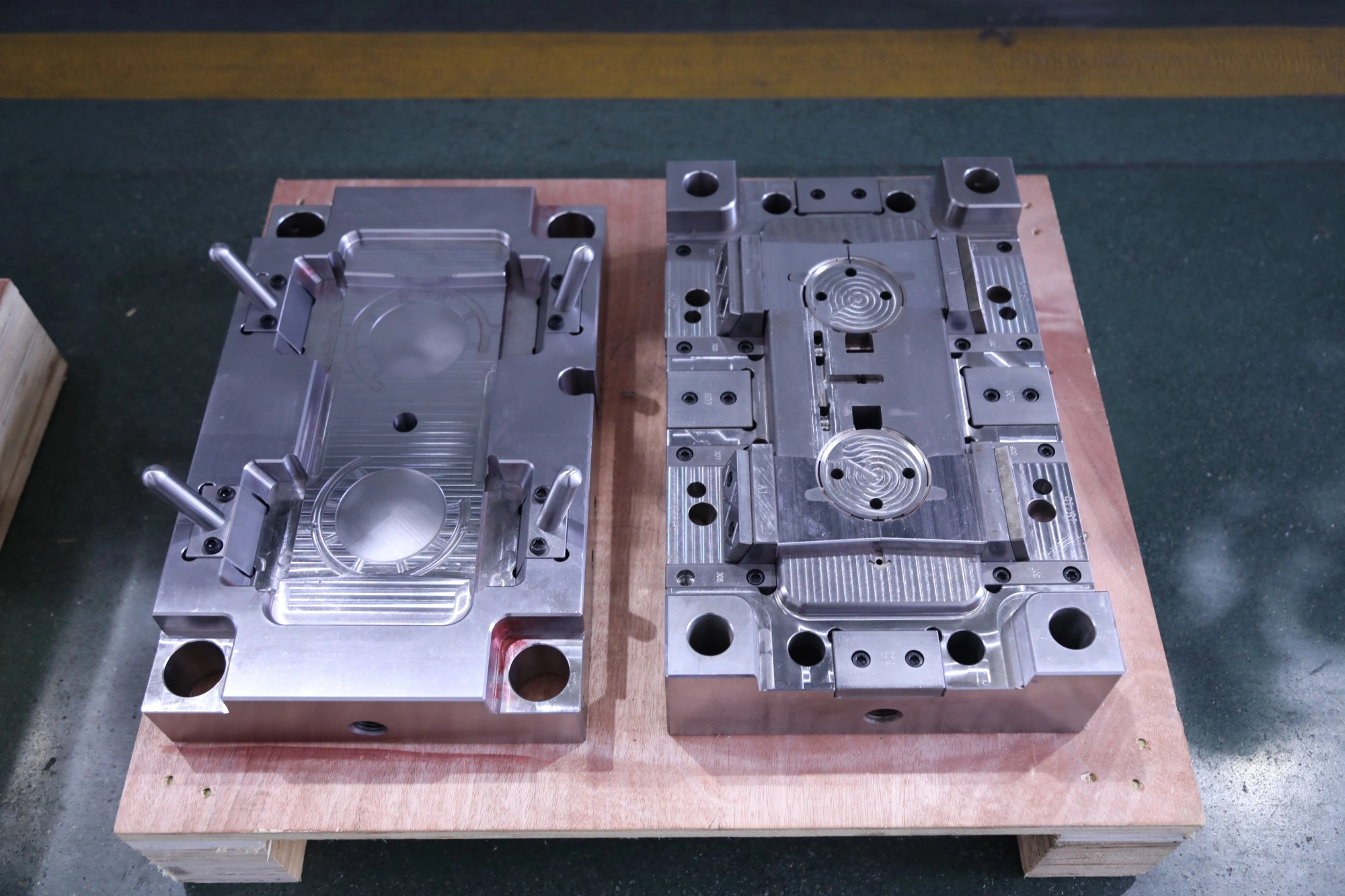

With over 18 years of experience in mold base manufacturing management, SG Mould Base leads the industry in innovation and semi-automated production. We empower enterprises with high-capacity, precision-engineered solutions that meet global standards.

Equipped with over 100 sets of high-precision CNC machinery and supporting equipment, we deliver more than 3,000 small and medium mold bases monthly. Our commitment to quality and efficiency ensures reliable performance across medical, automotive, and home appliance industries.

- 18+ Years of Industry Expertise

- 3000+ Monthly Mold Base Output

- 100+ High-Precision CNC Machines

- Global Export to 30+ Countries