About SINOBENDER

SINOBENDER INDUSTRIAL CO., LTD is a leading manufacturer of metal processing machinery with four specialized subsidiaries located in Nantong, Jiangsu Province, China. Since 1998, we have been delivering reliable, high-performance equipment to industries worldwide.

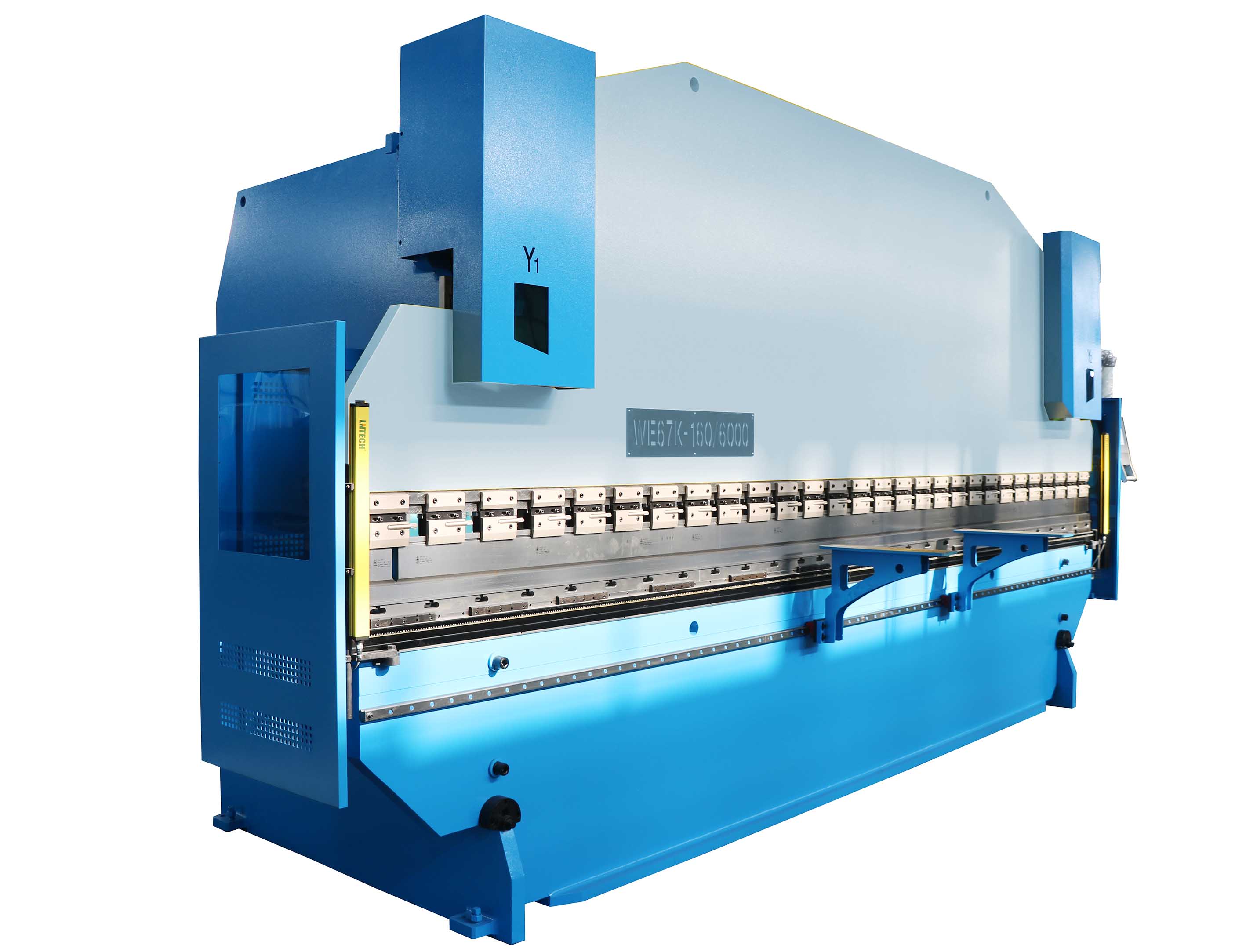

Our group includes Nantong Donghai Machine Tool Co., Ltd (press brakes and shearing machines), Nantong Huade Metal Forming Machine Co., Ltd (hydraulic presses), Nantong Zhongde Metal Forming Machine Co., Ltd (compact press brakes and ironworkers), and Nantong Union Machine Co., Ltd (plate bending machines).

With over 2000 machines produced annually, our equipment serves critical sectors including shipbuilding, petrochemicals, pressure vessels, bridge construction, wind energy, and automotive manufacturing.