ZHU ZHOU SHUANGLING TECHNOLOGY CO., LTD.

SLTZZ is a leading manufacturer of advanced industrial equipment specializing in metal powder production, vacuum processing systems, and precision manufacturing machinery. As a nationally recognized high-tech enterprise, we serve critical industries including aerospace, nuclear energy, and additive manufacturing.

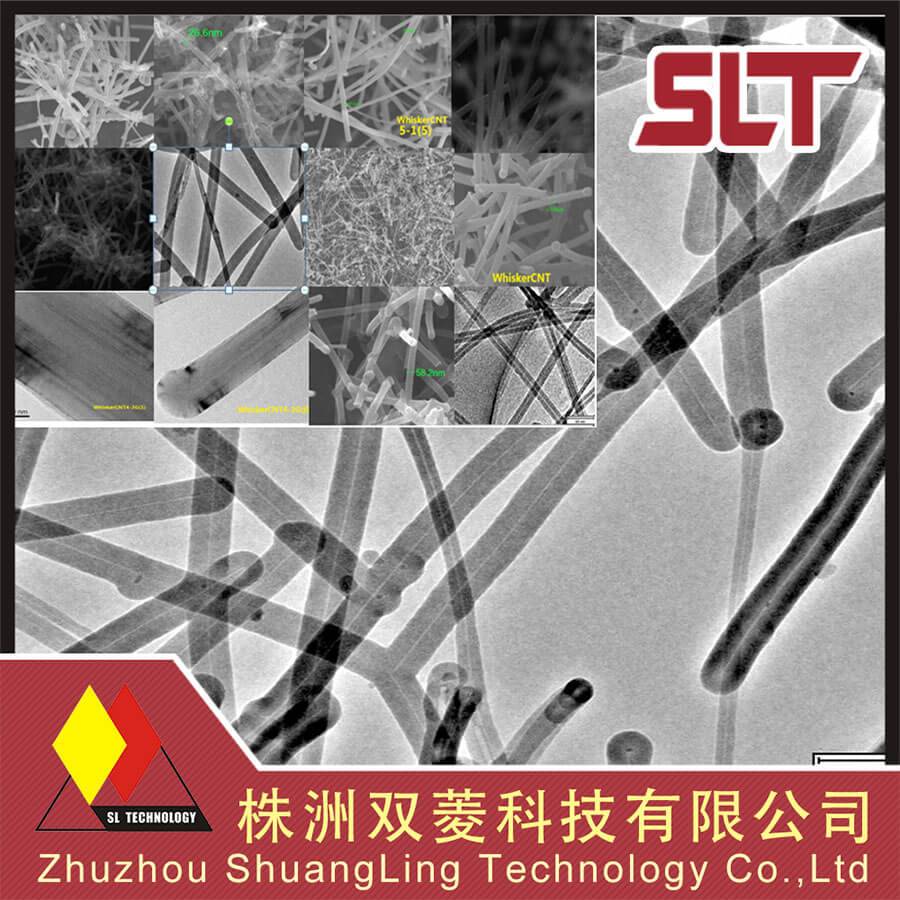

Our comprehensive product line includes gas and water atomization equipment, vacuum melting and sintering furnaces, carbon nanotube production lines, and specialized pipe processing machinery. We provide complete turnkey solutions for metal powder production facilities and advanced material processing plants.