Pioneering Smart Wire Rope Inspection

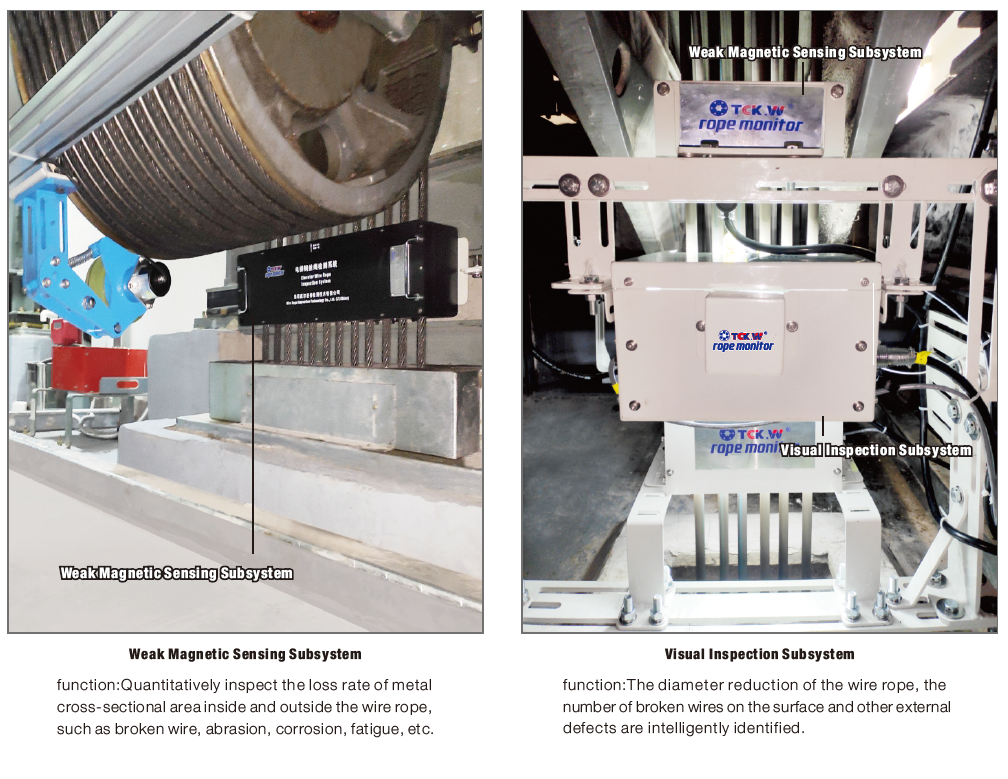

Luoyang Wire Rope Inspection Technology Co., Ltd. is the inventor of the world’s most advanced "magnetic memory wire rope AI weak magnetic detection technology" — known as TCK.W Technology. This breakthrough innovation enables accurate, non-invasive, and real-time detection of wire rope flaws including broken wires, abrasion, corrosion, and fatigue-induced strength loss.

Recognized globally, TCK.W technology was awarded the 2018 Offshore Technology Conference (OTC) Spotlight on New Technology Award in the USA — a testament to its engineering excellence and safety impact.