Premium Snack & Food

Processing Equipment

Trusted by manufacturers in over 80 countries. We deliver fully automated, cost-effective, and quality-stable production lines for snacks, pet food, noodles, and more.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

Trusted by manufacturers in over 80 countries. We deliver fully automated, cost-effective, and quality-stable production lines for snacks, pet food, noodles, and more.

Jinan Mingde Machinery Co., Ltd – A leading Chinese manufacturer of food extrusion and processing equipment since 1990.

With over 30 years of expertise, we are one of China’s most experienced manufacturers of puffed extruders and food machinery.

Our products are exported to more than 80 countries including the USA, Canada, Brazil, Poland, and Mexico.

We maintain a strong technical guarantee system through global partnerships and continuous innovation in extrusion technology.

A comprehensive selection of food processing lines and machinery for diverse applications.

Fully automated system for producing puffed snacks with high efficiency and consistent quality.

Complete 150kg/h fully automated popcorn production line with integrated drying and seasoning.

Produce fortified rice from corn, wheat, or legumes with precise nutrient control.

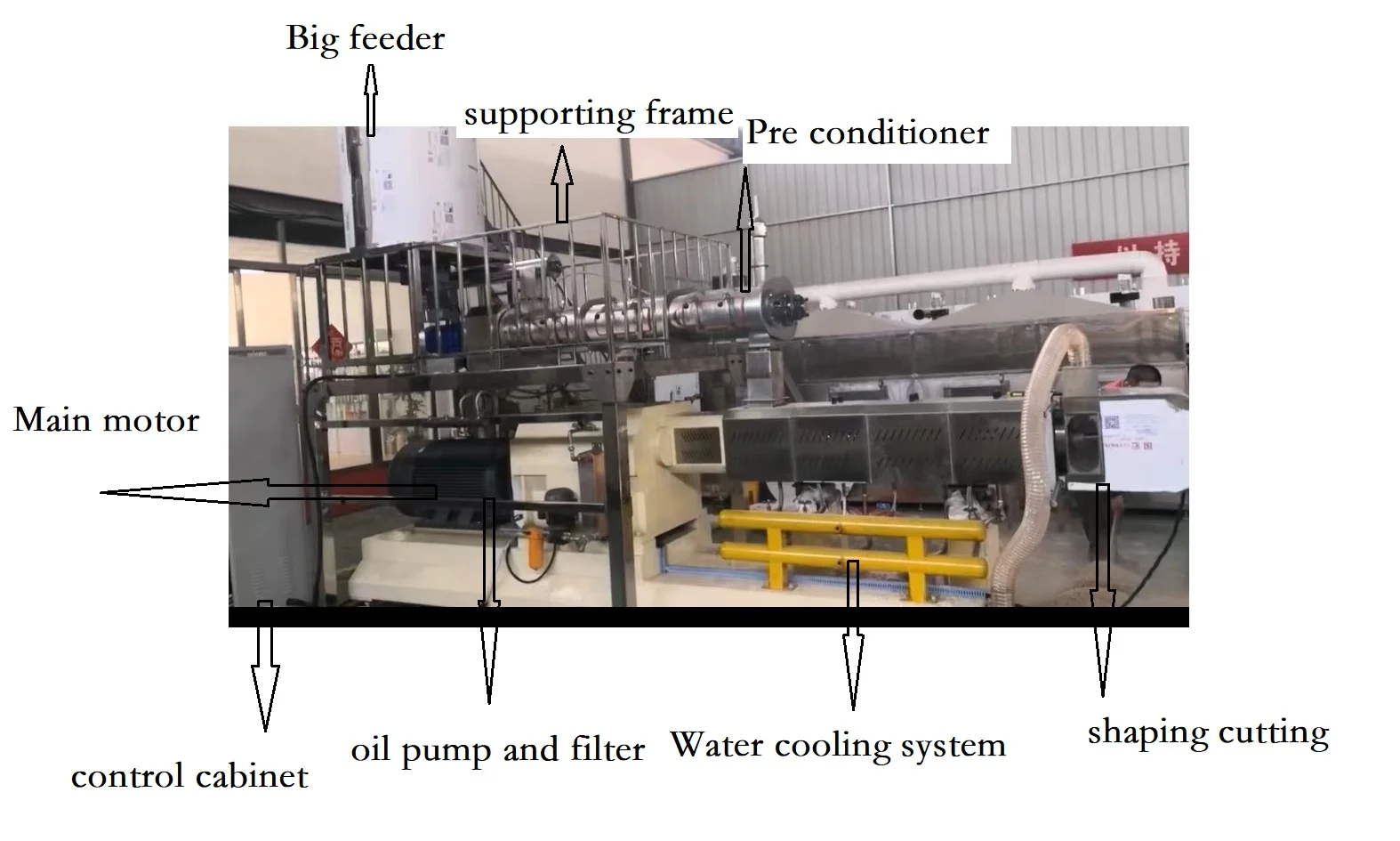

Advanced extrusion system for producing high-quality dry pet food and treats.

End-to-end solution for producing high-quality instant noodles with steaming, frying, and packaging.

Specialized system for producing nutritionally balanced food for herbivorous pets.

High-capacity system for producing popular corn-based snack shapes with consistent frying.

Upgraded multifunctional dryer for snacks, vegetables, and pet food with precise temperature control.

We deliver more than machinery — we deliver partnership, reliability, and innovation.

Our machines are built for durability and consistent performance, ensuring your production runs smoothly.

Optimized designs reduce energy and maintenance costs, delivering long-term value for your investment.

We guarantee to reply to your inquiry within 24 hours and provide ongoing technical support.

We partner with reliable logistics providers to ensure safe and timely delivery worldwide.

Get answers to common questions about our machinery and services.

Our twin-screw extruders can produce a wide variety of snacks including puffed corn, cheese curls, bugles, cereal snacks, and fortified rice alternatives.

Yes, we specialize in customized extrusion solutions tailored to your specific raw materials, capacity needs, and product specifications.

We offer comprehensive technical support, installation guidance, operator training, and ongoing maintenance assistance.

Production time is typically 30–45 days, followed by shipping. We coordinate logistics to ensure timely delivery based on your location.

Have questions about our machinery or need a quote? Contact us today.

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info