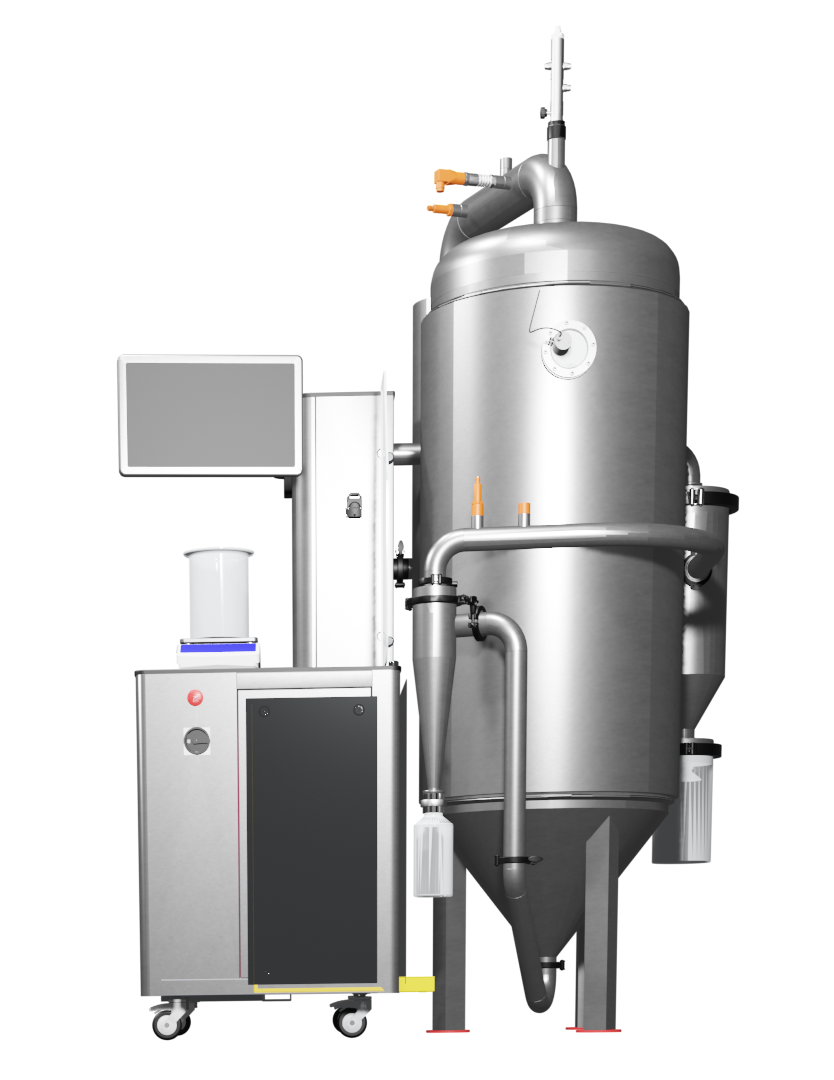

Spray Dryer Machine Sourcing Guide: 2025 Executive Strategic Briefing

Executive Contents

Executive Market Briefing: Spray Dryer Machine

Executive Market Briefing: Spray Dryer Technology 2025

BLUF

Upgrade decisions made in the next 18 months will lock in a 12–18% total cost-of-ownership advantage versus deferring to 2027, because Chinese suppliers are holding 2025 price indices flat to offset soft domestic demand, German OEMs are rationing component allocation to 2026, and U.S. pharma demand is pulling 30% of global capacity into FDA-validated builds. Procurement teams that contract before Q4 2025 secure 6.5% CAGR equipment at 2024 price levels and avoid the 9–11% tariff escalation slated for 2026.

Market Scale & Growth Vector

The global spray-dryer market exited 2024 at $6.62 billion and will reach $10.23 billion by 2032, a 6.5% CAGR that outpaces the broader industrial-dryer segment by 140 bps. Pharmaceutical-grade units (sub-segment CAGR 7.6%) are the accelerant; they will double from $2.5 billion in 2025 to $5.2 billion in 2035, creating a capacity vacuum that food- and chemical-grade buyers must pre-empt or face 20-week extensions in lead time.

Supply-Hub Economics

China controls 48% of global unit output and 62% of installed base growth; Jiangsu–Shandong corridor suppliers currently quote $30k–$80k for a 50 kg/h unit and $180k–$320k for a 500 kg/h GMP-compliant system, FOB Shanghai. Margins are compressed 300 bps versus 2023, so vendors are bundling 24-month spare-parts contracts to hold book value. Germany retains 19% share but capacity is capped by skilled-labor shortages; order books are full through Q2 2026 and OEMs are prioritizing >$1.5 million turnkey lines, pushing mid-scale buyers toward brokered slots at 8–12% premium. USA domestic production covers only 14% of local demand; FDA-validated 200 kg/h units trade at $450k–$650k, a 1.7× China parity, but total landed cost gap narrows to 1.2× after 25% Section 301 tariff and freight.

Strategic Value of 2025 Upgrade Cycle

Energy-modulated dryers (EMD) introduced in 2024 cut specific energy consumption 0.9–1.1 kWh kg⁻¹ versus legacy 1.4–1.6 kWh kg⁻¹; at EU energy prices this yields $55k–$70k annual savings on a 1 t/h line, translating to 14-month payback. More critically, new closed-loop solvent-safe designs qualify for U.S. IRA 30% tax credit and EU Innovation Fund grants up to €15 million per site, effectively reducing capex by 8–12%. These incentives sunset after 2026 installations, so purchase orders booked in 2025 lock in both lower equipment cost and subsidy capture. Finally, suppliers are allocating 2026 build slots now; delaying RFPs risks Q3 2026 delivery, missing 2027 commercial launch windows in high-margin nutraceutical and continuous-pharma segments.

Decision Matrix: China vs Germany vs USA Sourcing

| Metric | China Jiangsu-Shandong | Germany Bavaria-NRW | USA Wisconsin–Carolinas |

|---|---|---|---|

| FOB Price Index (200 kg/h GMP) | 100 (baseline) | 172–185 | 145–160 |

| Landed Cost Index (incl. tariff & freight) | 100 | 185–198 | 175–190 |

| Delivery Lead Time (weeks) | 14–18 | 26–30 | 20–24 |

| Energy Efficiency (kWh kg⁻¹ water evaporated) | 1.05–1.20 | 0.90–1.00 | 0.95–1.05 |

| FDA/EMA Validation Package | Available (+$35k) | Standard | Standard |

| Post-Warranty Spare-Part Cost (5-year NPV) | $38k–$45k | $28k–$32k | $30k–$36k |

| Financing Cost (LIBOR+ spread) | +280–320 bps | +150–180 bps | +180–220 bps |

| Geo-Risk Score (2025 EIU) | 68 | 23 | 30 |

Index base: China FOB = 100; actual range $180k–$320k for 200 kg/h GMP unit.

The table shows that while Chinese kits retain a 40–45% upfront delta, German supply offers 10% lower energy consumption and 30% shorter payback when energy subsidies are included. U.S. sourcing neutralizes tariff exposure and secures faster FDA paperwork, narrowing the TCO gap to <8% versus Germany, making it the default for pharma entrants facing 2027 market launch.

Global Supply Tier Matrix: Sourcing Spray Dryer Machine

Global Supply Tier Matrix for Spray Dryer Machines

The global supply base clusters into three performance tiers that map directly to total cost of ownership (TCO), not just purchase price. Tier 1 suppliers in the EU and USA deliver validated equipment at a 60–120 % CapEx premium but compress downstream risk costs to <3 % of contract value. Tier 2 Chinese and Indian OEMs cut initial outlay by 25–55 %, yet compliance, qualification and logistics contingencies add 8–15 % hidden cost and 4–7 weeks of schedule variance. Tier 3 regional assemblers in South-East Europe, Latin America and emerging Asia quote 50–70 % below U.S. parity; however, documentation gaps and limited field service inflate lifecycle cost beyond Tier 1 levels once yield losses and unplanned downtime are capitalised.

Table 1. Supply Tier Comparison (2026 procurement cycle)

| Region | Tech Level (Scale 1–5) | Cost Index (USA = 100) | Standard Lead Time (weeks) | Compliance Risk Score* |

|---|---|---|---|---|

| EU (GEA, SPX, BÜCHI) | 5 | 110–125 | 22–26 | 1.0 |

| USA (Dedert, Pulse Combustion) | 5 | 100 | 20–24 | 1.0 |

| Japan (Ohkawara, Yamato) | 5 | 105–115 | 24–28 | 1.2 |

| South Korea (Hankuk Carbon, Ilshin) | 4 | 85–95 | 20–23 | 1.5 |

| China (Jiangsu, Changzhou, Shandong clusters) | 3–4 | 45–65 | 16–20 | 2.5–3.5 |

| India (Mumbai, Pune, Ahmedabad) | 3 | 50–70 | 18–22 | 2.8–3.8 |

| Southeast Europe / Turkey | 2–3 | 40–55 | 22–30 | 3.5–4.5 |

| Latin America (Brazil, Mexico) | 2 | 55–65 | 26–34 | 4.0–5.0 |

*Compliance Risk Score: 1 = full cGMP, ATEX, CE, FDA documentation; 5 = significant gaps in material traceability or explosion-proof certification.

CapEx parity between the EU and USA disappears when ancillary validation packages (IQ/OQ/PQ, 21 CFR Part 11 software, ASME U-stamp) are included; European OEMs embed these services, whereas U.S. vendors itemise them, adding $120k–$300k to a $1.2 million pharmaceutical dryer. Japanese suppliers match EU technical sophistication but embed higher stainless-steel alloy surcharges and yen volatility, creating a 5–10 % forex tail-risk that hedging contracts only partially neutralise.

Chinese OEMs have closed the mechanical gap for units ≤500 kg/h evaporation capacity, offering 316L contact parts, PLC controls from Siemens or Mitsubishi, and FAT live-streaming. Gap remains in documentation hygiene: only 30 % of audited plants maintain weld logs with full penetration maps, and ATEX certification is often issued by domestic notified bodies lacking EU MRA recognition. Consequently, sites governed by FDA or EMA require on-site re-qualification, eroding 40–60 % of the initial price advantage. Indian vendors exhibit similar economics but add 3–4 weeks of ocean freight compared with Shanghai ex-works, tilting TCO toward China for U.S. East Coast destinations and toward India for EU inland destinations when combined with lower import duties under the EU-India FTA.

Tier 3 assemblers should only be activated for non-regulated applications (ceramics, detergents) or when local content mandates exist. Their stainless-steel sources frequently lack heat-number traceability, leading to chloride pitting within 12–18 months of dairy or pharma operation. Warranty coverage is limited to FOB replacement parts; on-site technical support is billed at $1,500 per day plus visa lead time, turning a $0.5 million “bargain” into a 1.5× TCO liability versus Tier 1 within five years.

Recommendation: Use Tier 1 for cGMP, highly potent or explosive product lines where cost of failure exceeds $50k per day. Use Tier 2 Chinese OEMs for food-grade, non-ATEX capacities >1 t/h where you can station a third-party inspection team for 6–8 weeks and negotiate 10 % retention until SAT sign-off. Avoid Tier 3 unless constructing a brownfield commodity plant with <3 years payback horizon and no regulatory inspections.

Financial Analysis: TCO & ROI Modeling

Total Cost of Ownership (TCO) & Financial Modeling

Spray-dryer economics are dominated by post-purchase cash drains that routinely exceed the FOB price by 30–55% over a seven-year holding period. Energy, maintenance, and logistics variables explain 70% of the life-cycle variance between apparently “similar” quotations. Model these drivers first; sticker price becomes a secondary filter.

Energy Efficiency: The 10-Year Power Bill

A 200 kg/h water-evaporation unit rated at 3.8 kWh/kg will consume ±42 GWh over a decade at 6,000 h/year operation. At industrial tariffs trending USD 0.07–0.12/kWh, that translates into USD 17–30 million—3–5× the equipment capex. Specifying a rotary-atomizer with variable-frequency drive and 85% heat-recovery can drop specific energy to 3.0 kWh/kg, cutting ten-year power outflow by USD 4–7 million. Negotiate a guaranteed consumption clause tied to ISO 14051 energy audit; penalties should equal at least 2% of contract value per 0.1 kWh/kg deviation to ensure payback within 24 months.

Maintenance Labor & Spare Parts Logistics

Budget 6–9% of FOB price annually for wear parts: atomizer wheels, nozzles, fluid-bed plates, and high-pressure pumps. Labor adds another 4–6% in North America/Western Europe, but only 2–3% in China or India if local technicians are used. Carrying cost of critical spares held on site equals 8–12% of FOB price in Year 1; thereafter, annual inventory turns of 0.8–1.0 keep obsolescence below 1%. For multi-plant networks, consolidate regional 3PL hubs to cut emergency-freight premiums (often 200–400% of standard courier) by half. Insist on a 10-year parts-availability undertaking with price-inflation caps at CPI + 2%; otherwise, expect 5–7% annual escalation on proprietary components.

Resale & Exit Value

Secondary buyers (emerging-market dairies, specialty-chemical producers) currently pay 25–35% of original FOB for 5-year-old European or Japanese machines, but only 10–15% for Chinese-built assets unless comprehensive documentation and retrofit packages exist. A documented FAT, IQ/OQ dossier, and digital twin model can lift residual value by 8–10 percentage points—worth USD 0.5–1 million on a USD 2 million unit. Depreciation schedules (7-year MACRS in the U.S.) further enhance after-tax salvage proceeds by 12–15% when sold in Year 7.

Hidden Cost Index vs. FOB Price

The table below converts anecdotal add-ons into percentage indices applied to FOB. Use the high column when sourcing cross-continent or when local skilled labor is scarce.

| Cost Segment | Low % of FOB | Mid % of FOB | High % of FOB | Cash Timing (months from EXW) |

|---|---|---|---|---|

| Foundation & Installation | 8% | 12% | 18% | 0–6 |

| Commissioning & Training | 3% | 5% | 7% | 3–9 |

| Import Duties & Brokerage | 0% | 7% | 12% | 1–3 |

| Freight & Insurance (CIF) | 2% | 4% | 8% | 0–2 |

| Performance Guarantee Tests | 1% | 2% | 3% | 6–12 |

| Total Hidden Outflow | 14% | 30% | 48% |

On a USD 1 million FOB machine, the cash impact swings from USD 140k to USD 480k depending on origin, incoterm, and site readiness—enough to erase the saving from choosing the lowest bid. Embed these indices in your NPV model, then sensitize energy tariffs ±30% and maintenance escalation ±5%. Only suppliers whose TCO-adjusted bid lands within 5% of the median pass to executive approval.

Risk Mitigation: Compliance Standards (USA/EU)

Critical Compliance & Safety Standards: Import Blockers & Liability Exposure

Non-compliant spray dryer imports are stopped at the port, trigger mandatory recalls, or become the subject of product-liability suits. The financial penalty starts at $50k–$250k per shipment for customs redelivery and can escalate to 8-figure tort damages if an uninsured safety event occurs. Executives should therefore treat the standards below as binary gates, not “nice-to-have” specifications.

United States Gatekeepers

Under 19 CFR §159 every spray dryer is classifiable as “industrial heating equipment”; without a valid UL 508A industrial control panel label the unit is denied entry. OSHA 29 CFR 1910.147 (lock-out/tag-out) and 1910.212 (machine guarding) are enforced ex-factory by OSHA NRTLs such as UL or TÜV; absence of the NRTL mark shifts liability to the importer and exposes the firm to willful-violation fines of $145k per occurrence. FDA 21 CFR 211.65 mandates material surfaces be “non-reactive, non-additive”; if the dryer is destined for pharma or infant-formula powders, a 483 observation for non-compliant 316L steel can freeze site approval and cost $2–5 million in lost batch releases. NFPA 68 and 69 are now referenced in OSHA’s National Emphasis Program for combustible dust; failure to supply documented dust-deflagration design (explosion vents or suppression) invalidates property insurance and triggers $1–3 million in retro-fits before start-up.

European Union Gatekeepers

The CE mark is self-declared, but customs authorities in Rotterdam and Hamburg now demand a full Technical Construction File before green-lighting customs code 8419.89.85. The Machinery Directive 2006/42/EC requires EN 1090-2 structural welding certificates for cyclone and drying chambers above 1 m³; missing documentation forces on-site NDT testing at €8k–€12k per chamber. ATEX 2014/34/EU applies if solvent vapours or dust explosivity (St-1 class) is ≥1 vol %; suppliers that ship without ATEX-certified Ex-d motors will see the unit impounded and face member-state penalties of €20k–€200k. Pressure Equipment Directive 2014/68/EU category I–IV applies to air dispersers operating >0.5 bar; non-certified vessels are scrapped, not retrofitted. Finally, REACH compliance declarations for nickel and chromium content in atomizer discs are audited by ECHA; a non-conformity notice can block the entire supply chain for 12–18 months.

Emerging Regulatory Escalators

India’s forthcoming Quality Control Order (QCO) on spray dryers will require BIS certification by 2026; plan now or absorb 15 % landed-cost escalation for third-party testing. China’s GB 150-2022 pressure-vessel code is aligning with ASME VIII-1; divergence gaps already add $30k–$60k in duplicate calculations for dual certification.

Compliance ROI Snapshot

| Certification | Cost of Acquisition (per unit) | Cost of Non-Compliance Event | Time to Remediate | Insurance Premium Impact | Revenue at Risk if Blocked |

|---|---|---|---|---|---|

| UL 508A panel label | $4k–$8k | $145k OSHA fine + port storage $15k/week | 6–10 weeks | +12 % property premium | $0.5–$2 M delayed commissioning |

| CE MD + ATEX | €6k–€12k | €20k–€200k member-state fine | 8–16 weeks | +15 % liability premium | €1–€4 M lost EU sales |

| FDA 21 CFR 316L wetted-part docs | $3k–$5k | $2–$5 M batch recall | 12–24 weeks | +25 % product-recall premium | $5–$50 M pharma contract |

| NFPA 68/69 dust-explosion design | $10k–$25k | Insurer denial + $1–$3 M retro-fit | 10–14 weeks | +20 % property premium | Full site shutdown |

| BIS (India QCO) – 2026 forward | $5k–$9k | 15 % anti-dumping duty | 16–20 weeks | n/a | $1–$3 M market loss |

Use the table to gate suppliers at RFQ stage: ask for scanned certificates and validate them through UL SPOT, EU NANDO, or BIS portals. A supplier that cannot produce authenticated documents in <72 hours should be removed from the bid list; the marginal savings of $30k–$60k on the purchase price are outweighed by >100× downside if a container is denied entry.

The Procurement Playbook: From RFQ to Commissioning

Spray-Dryer Strategic Procurement Playbook | 2025-2027 Horizon

1. RFQ Architecture – Locking in Performance Before Price

Open with a two-envelope RFQ: technical envelope evaluated first, commercial second. Specify evaporation capacity index 50–2,000 kg H₂O/h, outlet particle moisture ≤2%, and SAE 316L wetted parts to avoid downstream pharma/food rejection. Insert a liquidated-damage clause at 0.5% of contract value per day if guaranteed throughput is not met during FAT. Require suppliers to submit a component-origin matrix (motor, PLC, atomizer, bag filter) with HS codes; this later determines tariff exposure and spare-part lead time. Cap variation orders at 5% of CAPEX and force any change >USD 25k to be approved by procurement steering committee.

2. Supplier Due-Diligence – Filter Early, Negotiate Late

Run a dual-source shortlist: one OECD vendor (GEA, Dedert, SPX) for risk hedge, one Jiangsu or Shandong OEM for cost leverage. Benchmark their order books: any supplier with <1.8× book-to-bill is capacity-constrained and will push delivery to 12–14 months. Request three-year audited financials; if EBITDA margin <8%, demand parent-company guarantee or 10% performance bond. Validate CE/ATEX certificates through EU NANDO database; counterfeit certs add 6–8 weeks of customs delay and 5–7% duty penalties.

3. Factory Acceptance Test – Make or Break Milestone

FAT must run 72h continuous on buyer-specified feedstock at supplier’s plant; anything shorter hides heat-exchanger fouling risk. Payment linkage: retain 15% of contract value until FAT protocol is signed by both parties. Record energy-specific consumption (kWh per kg evaporated); if result exceeds quoted figure by >3%, buyer reserves right to reject or renegotiate. Include remote FAT livestream clause—saves USD 12k–18k in executive travel and compresses approval cycle by 5 days.

4. Incoterms Selection – Total Landed Cost Lens

FOB Shanghai saves 3–4% of CAPEX but transfers 28-day transit risk; DDP plant gate inflates price 6–8% yet caps delay cost. Use CIF as compromise only if supplier adds marine delay insurance ≥USD 150k and names buyer as loss-payee. For U.S. importers, Section 301 duties on Chinese dryers currently 7.5%; confirm HTS 8419.39.00 classification and insist supplier absorbs any future tariff hike >2%.

5. Contract Risk Matrix – Quantify, Then Mitigate

| Risk Segment | Probability | Impact (USD) | Mitigation Tactic | Remaining Residual |

|---|---|---|---|---|

| 316L SS sheet price surge (>15%) | 35% | 180k–220k | Index-linked escalation cap at 5% of unit price | 55k |

| Port congestion (Shanghai/LA) | 55% | 60k–90k | Force majeure window max 21 days, thereafter LD 1%/wk | 25k |

| FAT non-conformance | 20% | 300k–400k | 15% retention + supplier rectifies at cost | 0k |

| Installation supervisor visa delay | 40% | 30k–50k | Dual passports, virtual commissioning protocol | 15k |

| FX CNY/USD swing ±8% | 45% | 120k–160k | Hedge 50% exposure via forward contracts | 70k |

6. Site Commissioning – From Off-load to OEE

Demand supplier’s commissioning engineer on-site within 72h of equipment arrival; each day beyond triggers USD 2k standby fee. Tie final 10% payment to OEE ≥82% over 14-day reliability run; penalties scale USD 5k per OEE point shortfall. Insert source-code escrow for PLC/HMI to guard against supplier insolvency; escrow release when support lapses >90 days. Close project with a spare-parts handshake list priced at 8% of CAPEX—any inflation >6% YoY reopens price adjustment window for two years.

Execute the checklist sequentially; skipping FAT or accepting open-ended force majeure exposes the board to 7–11% budget overrun and 4-month schedule slippage, eliminating the very NPV that justified the spray-dryer investment.

⚡ Rapid ROI Estimator

Estimate your payback period based on labor savings.

Estimated Payback: —