About SW Machining

Welcome to Dongguan Shangwei Hardware Products Co., Ltd — a trusted provider of precision CNC machining services based in China. With years of experience and a commitment to excellence, we specialize in CNC turning, CNC milling, turning-milling compound machining, and limited production runs.

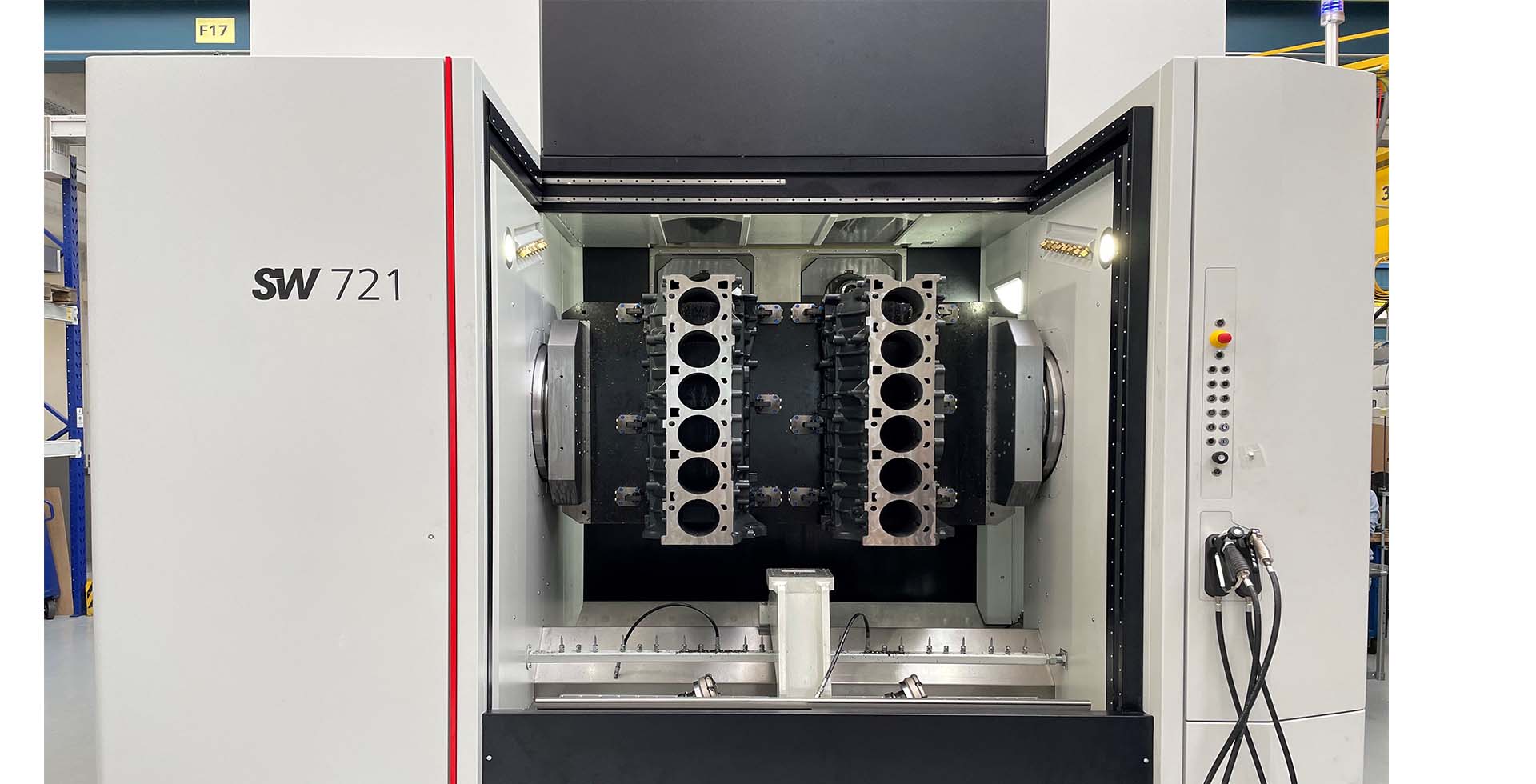

Our state-of-the-art facility is equipped with advanced 3, 4, and 5-axis machining centers, NC lathes, and comprehensive measuring instruments to ensure every component meets the highest standards of accuracy and quality.

We serve global industries including Aerospace, Medical Devices, Telecommunications, and Mechanical Engineering, delivering reliable, repeatable, and high-performance machined parts.