Viscosity Filling Machine: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for Viscosity Filling Machines

High-viscosity and particulate-laden products (pastes, creams, lotions, gels, chunky formulations) stress standard fillers. Accurate dosing, consistent nozzle performance, cleanability, and minimal product waste are the real bottlenecks.

This guide helps operations, engineering, and packaging leads in the USA and Europe choose, validate, and integrate viscosity fillers that scale from bench to line.

What you’ll learn:

– Machine categories and where piston fillers excel

– Critical specs: materials (e.g., 316 SS contact parts), seal compatibility, nozzle design, controls, and changeover

– Compliance and sanitation: food-grade contact, sanitize-in-place protocols, Prop 65 considerations (US)

– Line integration: container handling, automation layers, and safety

– Total cost of ownership (TCO): throughput vs. downtime, spare parts, maintenance, validation

– Supplier due diligence: documentation, certifications, service, and delivery

How to use this guide:

– Start with decision criteria table

– Evaluate models using the spec checklist

– Define your application profile and risk profile

– Build a pilot plan and define acceptance criteria

– Finalize supplier shortlist and implement

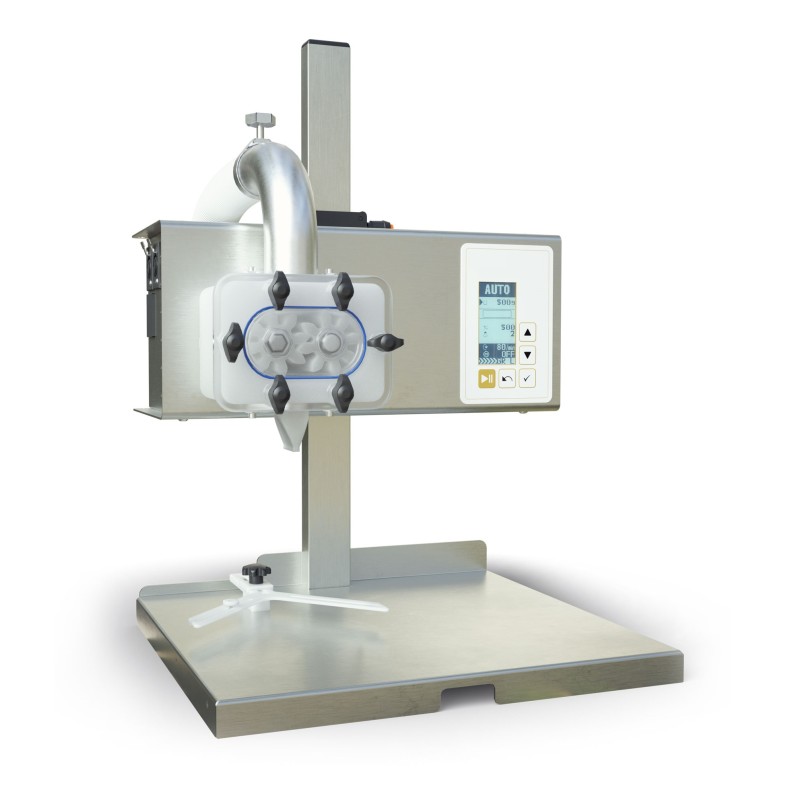

A practical anchor point is a tabletop high-viscosity piston filler with 316 SS contact parts, foot actuation, adjustable dosing, and an anti-leak nozzle—ideal for pastes, creams, gels, and products with large particulates. Use the tables and checklists to adapt this baseline to your volume, container format, and compliance requirements.

Illustrative Image (Source: Google Search)

Top 10 Viscosity Filling Machine Manufacturers & Suppliers List

1. Top 10 Liquid Filling Machine Manufacturers – HonorPack

Domain: honorpack.com

Registered: 2009 (16 years)

Introduction: Accutek Packaging Equipment has become a top liquid filling company. This is a USA-based manufacturer that was established in 1989. They create machines for ……

2. Product Viscosity and Filling Machines – Liquid Packaging Solutions

Domain: liquidpackagingsolution.com

Registered: 2006 (19 years)

Introduction: LPS manufactures a range of filling machines to handle different product viscosities with different filling principles.Missing: top suppliers…

3. Viscous Liquid Filling Machine – Levapack

Domain: levapack.com

Registered: 2018 (7 years)

Introduction: Levapack is a leading custom viscous liquid filling machine manufacturer. This Chinese company is located in the Guangdong Province and maintains a 2000 sq ……

Understanding viscosity filling machine Types and Variations

Understanding Viscosity Filling Machine Types and Variations

Choosing the right viscosity filling machine requires aligning product rheology (viscosity, shear sensitivity, particulate size) with volumetric control method, materials of construction, and sanitation requirements. While many fill principles exist, five types dominate viscous and semi‑viscous applications across the USA and Europe: Piston, Peristaltic, Gear Pump, Time‑Pressure (for low‑viscosity viscous streams), and Diaphragm. Each balances accuracy, shear, cleanability, and cost differently.

Quick‑Reference Comparison

| Type | Features | Applications | Pros/Cons |

|---|---|---|---|

| Piston (Volumetric) | Fixed‑displacement cylinder; 316/304 SS contact; foot/auto actuation; anti‑drip nozzle | Pastes, creams, lotions, gels, chunky particulates | + High volumetric accuracy and repeatability; suitable for large particulates; food‑grade SS. − Shear/gentle blend sensitivity; volume change requires manual adjustment/change parts. |

| Peristaltic Pump | Pumped tube; wetted path = tube; easy sanitize; closed‑loop flow | Low to high viscosity; shear‑sensitive, sterile, abrasive slurries | + Gentle on product; fast changeover; no valves to clog. − Tube life cost; lower accuracy vs. piston at high viscosity. |

| Gear Pump | Positive displacement gears; 316 SS wetted parts; mechanical seals options | Sauces, peanut butter, syrups, adhesives | + Strong suction; handles higher viscosity than many pumps. − Higher shear; particulate limits; wear on abrasives; dead‑leg management. |

| Time‑Pressure (for viscous streams) | Timed pressure pushes product through nozzle into open container; simple | Low‑to‑mid viscosity liquids with good flow; no particulates | + Low cost; fast; simple. − Accuracy sensitive to temp/viscosity; not suited to chunks. |

| Diaphragm Valve | Sandwich valve design; hygienic; sanitizable; clean‑in‑place capable | Viscous liquids, sterile or hygienic processing | + Hygienic design; good cleanability; reduced product loss. − Larger footprint vs. peristaltic; setup can be more involved. |

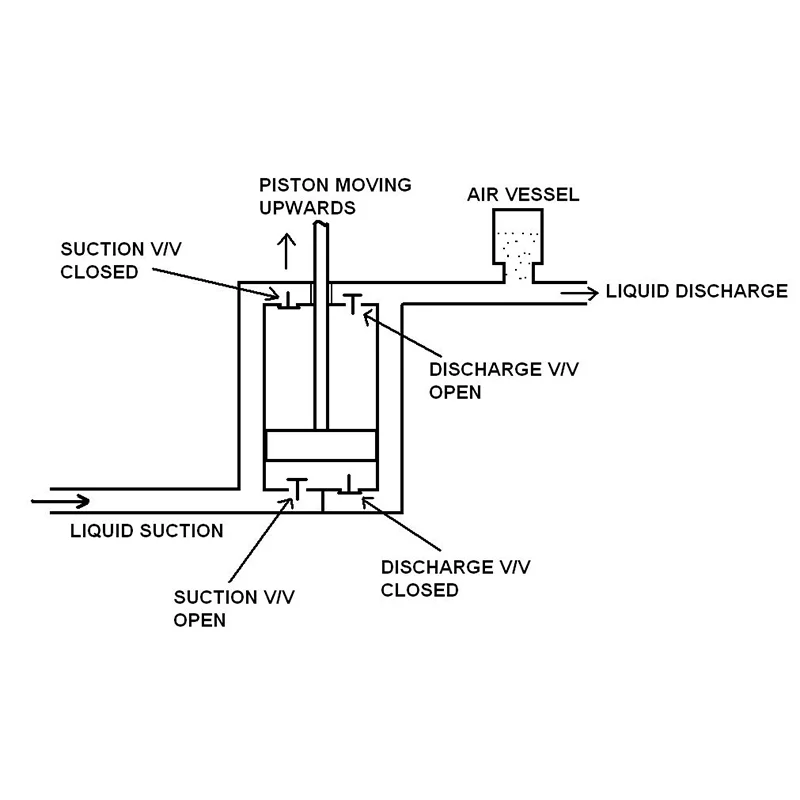

Piston Fillers (Volumetric)

Piston fillers deliver a fixed volume by drawing and discharging a product slug through a piston‑driven cylinder. The tabletop unit described (e.g., 316 SS wetted parts, foot activation) targets thick and semi‑viscous products, including those with large particulates. Typical features include 316 SS contact surfaces, stainless shell, simple operator interface, adjustable dispense volume, anti‑drip nozzle, and compact bench placement.

- Applications: Pastes, creams, lotions, gels, sauces with particulates, and products that require precise volumetrics.

- Pros: High accuracy and repeatability; robust for viscous/chunky products; sanitary materials; easy sanitization; straightforward operation with minimal training.

- Cons: Product shear/gentle blending sensitivity; volume change requires adjustment or change parts; foot switch vs. automatic cycle affects throughput.

Peristaltic Pumps

Peristaltic pumps move product via a rotating roller that compresses a tube, creating flow without exposing the product to valves or rotors. The wetted path is only the tube, which simplifies sanitation and changeover.

- Applications: Low to high viscosity liquids, sterile or shear‑sensitive products, abrasive slurries where pump internals would wear (e.g., certain lotions, gels, light pastes, specialty coatings).

- Pros: Gentle handling; quick, tool‑free tube change; cleanable; closed product path; fast recipe changeover.

- Cons: Tube wear requires replacement; accuracy can lag piston systems at higher viscosities; tube material compatibility must be verified.

Gear Pumps (Positive Displacement)

Gear pumps use intermeshing gears to pull and push viscous products through the pump chamber. Mechanical seals can be specified to handle abrasive or sticky materials, and 316 SS contact parts are common.

- Applications: Sauces with medium particulates, peanut butter, syrups, adhesives, and similar viscous, pumpable products.

- Pros: Strong suction and positive displacement up to high viscosity; good throughput; can handle thicker products than many pumps.

- Cons: Higher shear; limited size for large particulates; wear with abrasive fills; careful design to avoid dead legs and ensure sanitization.

Time‑Pressure Filling (for viscous streams)

Time‑pressure systems rely on timed pressurization of a supply vessel to push product through a nozzle into open containers. While often applied to low‑viscosity liquids, they can suit viscous streams with adequate flow.

- Applications: Low to mid viscosity liquids that flow consistently and contain no particulates (e.g., thinner lotions, syrups, light gels).

- Pros: Low capital cost; high speed; simple setup.

- Cons: Accuracy sensitive to temperature, viscosity, and head pressure; unsuitable for products with chunks or high variability.

Diaphragm Valve Systems

Diaphragm valves provide a hygienic, sanitizable sandwich design that controls flow with a moving diaphragm. Hygienic standards and cleanability are strong advantages.

- Applications: Viscous liquids in hygienic or sterile environments, particularly in food, beverage, and life‑science adjacencies.

- Pros: Hygienic design, good cleanability, reduced product residue; suitable for more viscous liquids.

- Cons: Larger footprint vs. peristaltic; more complex setup; may require more engineering effort to optimize for specific viscous products.

Selecting a Viscosity Filling Machine

Use the following practical criteria to narrow choices:

– Product rheology: Viscosity range, shear sensitivity, particle size.

– Accuracy needs: Required tolerances and repeatability.

– Sanitation level: Food‑grade, CIP/SIP readiness, materials of construction (e.g., 316 SS contact parts).

– Changeover and uptime: Tool‑free sanitation, tube/piston adjustments, time to switch SKUs.

– Throughput and controls: Foot pedal, auto cycle, volumetric adjustment, anti‑drip features.

– Maintenance: Tube life, seals, and availability of spare parts and support in USA/EU.

Illustrative Image (Source: Google Search)

For thick/chunky pastes and creams where accuracy and sanitized stainless contact matter, a piston filler with 316 SS wetted parts is the baseline. For shear‑sensitive or sterile products, peristaltic or diaphragm configurations are often better. For pumpable viscous streams without particulates, gear pumps or time‑pressure can provide cost‑effective throughput. Align machine selection with product characteristics and operational requirements to achieve stable fills and sustainable total cost of ownership.

Key Industrial Applications of viscosity filling machine

Key Industrial Applications of Viscosity Filling Machines

Use cases where viscous, semi-viscous, and chunky products demand accurate, clean, and repeatable filling. This section highlights application fit and selection criteria for piston-style viscosity fillers in US/EU B2B environments.

Industry-to-Application Mapping and Spec Notes

| Industry | Typical Applications | Example Products | Recommended Fill Range | Required/Preferred Features | Notes for USA/EU Buyers |

|---|---|---|---|---|---|

| Food & Beverage | Sauces, condiments, syrups, honey, caramel, batters, dressings | Tomato sauce, BBQ sauce, ketchup, honey, chocolate syrup, peanut butter | 10–500 ml | 316 SS contact parts; anti-drip nozzle; foot pedal; adjustable volume | Supports batch portability and small-run production; 316 SS supports CIP/SIP |

| Cosmetics & Personal Care | Creams, lotions, gels, serums, toothpaste, masks | Face cream, hand lotion, shampoo, aloe gel, toothpaste | 10–500 ml | 316 SS contact parts; non-drip nozzle; compact benchtop; adjustable volume | Suitable for compliant cosmetic filling; easy sanitation between SKUs |

| Pharmaceuticals & Nutraceuticals | Ointments, gels, syrups, topical creams | Wound ointment, medicated gel, syrup | 10–500 ml | 316 SS contact parts; foot activation; adjustable volume; easy cleaning | Verify regulatory compliance of materials and downstream validation |

| Chemicals & Household | Paste cleaners, lubricants, detergents, gap fillers, sealants, caulks | Tile adhesive, caulking paste, liquid detergent, thick cleaner | 10–500 ml | 316 SS contact parts; anti-leak nozzle; pneumatic actuation (if available); adjustable volume | Pneumatic options common for chemical environments; ensure nozzle/no-drip for viscosity |

| Automotive | Greases, lubricants, protective coatings, gasket makers | Motor oil paste, brake grease, undercoating paste | 10–500 ml | Heavy-duty construction; anti-drip nozzle; adjustable volume | Benchtop units useful for service filling; ensure material compatibility |

| Adhesives & Sealants | Epoxy pastes, RTV sealants, construction adhesives | Silicone sealant, epoxy paste | 10–500 ml | 316 SS contact parts; anti-drip nozzle; compact size | Accurate volumetric dosing critical for cure consistency |

Detailed Benefits by Use Case

- High-viscosity and chunky products: 316 SS piston and contact parts handle thick pastes, creams, lotions, gels, and products with large particulates without degradation.

- Accuracy and repeatability: Volumetric piston design delivers exact measurements batch-to-batch, reducing giveaways and rework.

- Clean, mess-free production: Anti-leak/no-drip nozzle minimizes product waste and work area contamination, sustaining cGMP hygiene.

- Faster throughput with hands-free operation: Foot activation accelerates cycle time while freeing operator hands for container handling.

- Easy sanitation: Smooth 316 SS surfaces, tool-free disassembly, and simple cleaning reduce changeover time between SKUs and support CIP/SIP practices.

- Versatility on limited floorspace: Compact benchtop footprint fits any workbench or table, enabling scalability without retooling the entire line.

- Durable build for industrial use: 304 SS shell and heavy-duty construction provide long-term reliability and reduced maintenance overhead.

Spec-to-Application Quick Selector

| Viscosity/Particle | Typical Product Types | Suggested Nozzle ID | Fill Range | Activation | Notes |

|---|---|---|---|---|---|

| Semi-viscous (syrups, lotions) | Syrups, honey, lotions, gels | 6–12 mm | 10–500 ml | Foot pedal | Precision fills with non-drip control |

| High-viscosity (creams, sauces) | Creams, sauces, peanut butter | 12–19 mm | 10–500 ml | Foot pedal | Handles higher solids; prevents nozzle clogging |

| Chunky/particulate | Tomato sauce with chunks, cleaners with grit | 15.5–19 mm | 10–500 ml | Foot pedal | Larger passages maintain flow and accuracy |

Compliance and Safety Notes

- Materials: 316 SS contact parts align with FDA/EU food-contact expectations; confirm gasket materials for product-specific compliance.

- Pneumatics and labeling: Units may be pneumatic-actuated in some models; review EU/US pressure equipment and safety labeling requirements as applicable to your configuration.

- Proposition 65: Certain products and packaging materials may trigger CA Prop 65 requirements; perform supplier disclosure and risk assessment for your specific use case.

Why Choose a Piston-Style Viscosity Filler

For viscous, semi-viscous, and particulate-laden products, piston fillers offer robust volumetric control, fast cycle times, and superior cleanability versus peristaltic or gravity systems. In regulated and hygiene-sensitive environments, the combination of 316 SS contact parts, anti-drip dispensing, and tool-free sanitation translates to less rework, lower scrap, and quicker SKU changeovers.

3 Common User Pain Points for ‘viscosity filling machine’ & Their Solutions

3 Common B2B Pain Points for Viscosity Filling Machines & Their Solutions

Pain Point 1 — Nozzle Dripping and Stringing (mess, waste, slow throughput)

- Scenario: Handling thick pastes, creams, gels, or products with large particulates causes stringing or dripping at the nozzle, contaminating containers and the work area.

- Problem: Product waste, inconsistent net weight, and extra cleanup time.

- Solution:

- Use a non-drip, anti-leak nozzle; pair it with a proper orifice size to match the product’s viscosity and particle size.

- Select a volume stroke that balances speed and control; for very viscous fills, shorten stroke or reduce pressure to minimize stringing.

- Adopt a foot-activation workflow so operators can time cycles precisely, reducing post-fill drip at the nozzle.

- Relevant machine features:

- Anti-leak nozzle (Type B), adjustable dispensing measurements, foot activation.

Pain Point 2 — Inconsistent Fill Volumes (weight/accuracy issues)

- Scenario: Same product and setup, yet batches show overfill/underfill or drift over time.

- Problem: Rework, scrap, customer complaints, and unstable OEE.

- Solution:

- Rely on a volumetric piston filler with accurate, repeatable volume control and easy micro-adjustability.

- Standardize cycle triggers using foot pedal operation to minimize operator-to-operator variation.

- Maintain consistent material temperature and pre-shearing to reduce viscosity fluctuations that cause weight variance.

- Relevant machine features:

- Exact volumetric measurements, adjustable dispensing measurements, foot activation for repeatability.

Pain Point 3 — Difficult Sanitation and Slow Changeover

- Scenario: Product residue on wetted parts and long turnaround between SKUs or between runs of different materials.

- Problem: Downtime, risk of cross-contamination, and increased cleaning effort.

- Solution:

- Choose a tabletop filler with all product-contact parts in 316 stainless steel for durability and cleanability, and a 304 SS shell for structural strength.

- Prioritize a tool-less disassembly design and smooth, polished surfaces that resist trapped residue and are easy to sanitize.

- Use food-grade elastomer seals and maintain a standard gasket set to simplify replacements during changeovers.

- Standardize cleaning procedures and define CIP-compatible wetted materials where applicable.

- Relevant machine features:

- 316 SS contact parts; 304 SS shell; stainless steel construction; simple, tool-free cleaning.

Quick comparison table

| Pain Point | Symptoms | Root Cause | Recommended Solution |

|---|---|---|---|

| Nozzle drip/stringing | Mess, waste, slow lines | Nozzle design mismatch to product | Non-drip, anti-leak nozzle sized to product; foot trigger |

| Inconsistent fill volumes | Over/underfill, drift | Repeatability and viscosity variability | Volumetric piston; precise, adjustable controls |

| Difficult sanitation/slow changeover | Long downtime, cross-contamination risk | Complex disassembly; non-food-grade parts | 316 SS contact parts; 304 SS shell; tool-free cleaning |

Summary:

– Match nozzle design and stroke settings to the product’s viscosity and particle size.

– Use volumetric piston control with precise adjustment and foot activation to stabilize accuracy.

– Favor 316 SS wetted parts and 304 SS enclosure with tool-less cleaning to reduce sanitation time and risk.

Strategic Material Selection Guide for viscosity filling machine

Strategic Material Selection Guide for Viscosity Filling Machines

This guide translates a representative, high‑viscosity tabletop piston filler (JORES TECHNOLOGIES model E-FP-500-D) into practical material decisions that align with USA and EU regulatory expectations and production realities. Where specifications are model‑specific, typical industry practices are noted.

Representative configuration

– Product-contact: 316 stainless steel (316 SS)

– Non-contact frame: 304 stainless steel (304 SS)

– Elastomer gaskets: Silicone (VMQ), D8 rubber (typically NBR), Type B spider gasket in nozzle (NBR/EPDM)

– Nozzle tip: Non-drip 15.5 mm

– Sensor/controls: Magnetic switch (no product contact)

– Sanitation: Tool‑free disassembly, designed for easy wipe-down/CIP compatibility

Why materials matter for viscous fills

– Accuracy: Positive displacement (piston) depends on volumetric repeatability. Smooth, clean surfaces and verified gasket compression prevent backflow and inconsistent volumes.

– Cleanliness: Viscosity and particulates trap debris. Open, drainable design and compatible elastomers are essential to avoid residue buildup and product contamination.

– Chemical resistance: Elastomers must resist the product’s oils, acids/bases, and cleaning chemistries (alkaline CIP, alcohol sanitizers).

– Mechanical integrity: For chunky or high-viscosity materials, nozzle and valve materials need abrasion resistance and robust seals to prevent “stringing,” dripping, and wear.

Illustrative Image (Source: Google Search)

Model‑confirmed material set (E-FP-500-D)

– 316 SS product-contact parts: Durable, corrosion-resistant, easy to sanitize; suitable for acidic and aqueous products and compatible with common CIP agents. Non‑porous, supports fine finishes.

– 304 SS non‑contact shell/structure: Cost-effective structural stainless; supports the 316 SS contact zone and overall rigidity.

– Silicone gaskets (1.5″, 2″, 2.5″, 3″): Flexible, food‑grade, resilient sealing with broad temperature tolerance; good for dairy, confectionery, and neutral foods. Not ideal for high‑aromatic oils.

– D8 Rubber Seal (Buna‑N/NBR): Cost-effective oil/grease seal; suitable for hydrocarbon‑containing pastes; not recommended for ketones, strong oxidizers, or hot steam SIP.

– Type B Spider Gasket for nozzle (NBR/EPDM typical): Ensures positive shutoff at the nozzle tip; selection depends on product chemistry (see matrix).

– Non‑drip nozzle tips (15.5 mm and 19 mm available): Designed to minimize dripping; reduces rework and contamination risk.

– Magnetic switch sensor: Sensing component, non-contact, mounted away from product path.

– Sanitation: Tool‑free dismantling and smooth SS surfaces reduce cleaning downtime; compatible with CIP and alcohol-based sanitizers.

Regulatory alignment (USA/EU)

– FDA 21 CFR 177.2600 for rubber articles intended for repeated contact with food (D8 rubber).

– EU 1935/2004 and EU 10/2011 for food‑contact materials and plastics (silicone gaskets typically evaluated under Good Manufacturing Practice with migration-specific testing).

– Stainless steel 316/304: Generally recognized as safe and suitable for food-contact when properly finished and maintained.

Material-to-application matrix for viscous fills

– 316 SS (product-contact)

– Strengths: Excellent corrosion resistance; smooth finishing; compatible with CIP; abrasion-resistant.

– Considerations: Avoid chloride pitting above ~60 °C or with heavy salt; select appropriate finishing to support cleanability.

– Best for: Pastes, creams, lotions, gels, and products with particulates; mild acid/alkaline; CIP environment.

– 304 SS (non-contact)

– Strengths: Structural rigidity; cost-effective; good general corrosion resistance in ambient conditions.

– Considerations: Avoid prolonged exposure to aggressive chloride media; non-product-contact.

– Silicone (VMQ) gaskets

– Strengths: Wide temperature window (~−60 to +200 °C), food‑grade, flexible, cleanable; resists aqueous and dairy products.

– Limitations: Swells with oils/solvents; may compress set under high torque; use with compatible nozzles/clamps.

– NBR (D8 rubber; nozzle spider)

– Strengths: Excellent for hydrocarbon oils/fats/greases; low cost.

– Limitations: Not for ketones, strong oxidizers, hot steam SIP; limited high‑temp service.

– EPDM (typical Type B nozzle spider substitute)

– Strengths: Steam resistance; good for detergents, caustic/acid solutions; broad temperature range.

– Limitations: Poor with hydrocarbon oils.

– FKM (Viton, optional upgrade)

– Strengths: Superior solvent/oil resistance; high temperature.

– Limitations: Higher cost; compression set; check flavor/aroma compatibility (swelling risk).

– Electropolish (upgrade)

– Strengths: Improved cleanability and corrosion resistance by reducing micro‑crevices and roughness; preferred in hygienic/harsh environments.

USA vs EU considerations

– Compliance: Align with FDA and EU 1935/2004 (and 10/2011 for plastics). Obtain material certificates and compliance declarations from suppliers where required.

– Thread/connector standards: Tri‑clamp gasket sizes typically use imperial imperial dimensions in the USA (e.g., 1.5″, 2″, 2.5″, 3″) and are widely accepted in EU food processing. Verify torque and gasket orientation per hygienic clamp standards.

– Cleaning regimes: CIP/SIP is common in both regions. Confirm gasket compatibility with hot steam (EPDM) vs steam‑limited elastomers (NBR, silicone).

– Environmental: Elastomer waste is non-recyclable in most regions; plan for replacement intervals. Stainless steel and aluminum housings are highly recyclable.

Illustrative Image (Source: Google Search)

Recommended selections by viscosity/use case

– High‑viscosity pastes with oil/fat content (lotions, creams, nut butters, sauces with oil)

– Product-contact: 316 SS

– Gaskets: NBR for oil zones; EPDM in steam/external interfaces; consider FKM for solvent resistance and high-temp lines.

– Nozzle tip: 316 SS non‑drip tip; Type B spider gasket in NBR or FKM

– Aqueous gels and shampoos

– Product-contact: 316 SS

– Gaskets: Silicone (e.g., 2″, 2.5″) for flexibility and temperature range; EPDM for steam lines

– Nozzle tip: 316 SS non‑drip; silicone tip or spider where feasible

– Products with particulates/chunky solids (salsas, relishes, cosmetic creams with beads)

– Product-contact: 316 SS with abrasion‑resistant finish

– Gaskets: NBR/EPDM spider; verify particulate passage; ensure nozzle tip minimizes stringing

– Acidic or caustic products

– Product-contact: 316 SS

– Gaskets: EPDM (alkaline/acidic CIP) or FKM for solvent/acid; avoid NBR for strong oxidizers/acids

– Dairy/confectionery (sugar/butterfat) with high temp cleaning

– Product-contact: 316 SS

– Gaskets: EPDM or silicone for sealing; confirm thermal cycles and fat migration; specify compliant elastomers for dairy if required

Material comparison table

| Material / Component | Primary use in machine (E-FP-500-D) | Key strengths | Limitations / notes | Typical temp range (contact) | Regulatory considerations | Recommended by viscosity/use case |

|---|---|---|---|---|---|---|

| 316 SS (product-contact) | Cylinder, nozzle body, wetted surfaces | High corrosion resistance; cleanable; CIP-compatible; abrasion‑resistant | Chloride pitting > ~60 °C; verify finish for hygienic service | Up to ~260 °C (static) | FDA‑safe, EU‑compliant w/ proper finishing | All high‑viscosity pastes/creams; chunky particulates; acidic/alkaline |

| 304 SS (non-contact) | Frame/shell | Structural rigidity; cost-effective; general corrosion resistance | Lower chloride tolerance than 316; avoid aggressive environments | Ambient to ~800 °C (structure) | — | Structural support for all models |

| Silicone (VMQ) gaskets | Tri‑clamp seals (1.5″, 2″, 2.5″, 3″) | Flexible; food‑grade; broad temp range; easy to sanitize | Swells with hydrocarbon oils/solvents; possible compression set | ~−60 to +200 °C | FDA 21 CFR 177.2600; EU 1935/2004 | Aqueous gels, shampoos, dairy/confectionery; avoid high oil content |

| NBR (D8 rubber) | Dynamic seals in piston/nozzle areas | Excellent oil/grease resistance; cost-effective | Poor with ketones/strong oxidizers; limited steam SIP | ~−40 to +110 °C | FDA 21 CFR 177.2600 | Oil/fat‑containing pastes; creams; avoid steam and ketone‑based chemistries |

| EPDM (typical for spider) | Nozzle spider (typical Type B) | Steam/caustic/acid resistant; good detergent compatibility | Poor with hydrocarbon oils | ~−50 to +150 °C | FDA 21 CFR 177.2600; EU 1935/2004 | CIP/SIP lines; caustic/acid; steam‑sterilized areas; avoid oil‑dominant products |

| FKM (Viton, optional) | Nozzle spider/valve seals (optional upgrade) | Superior solvent/oil resistance; high temperature | Higher cost; compression set; flavor/aroma migration risk; verify compliance | ~−20 to +200 °C | Check supplier compliance declarations | Aromatic oils, solvent‑containing products, high‑temp viscous fills |

| 316 SS non‑drip tip | Nozzle tip (15.5 mm; 19 mm option) | Clean cut‑off; reduces dripping; robust | Select spider/gasket to suit tip; verify clearance for particulates | As per SS | — | All viscous/chunky fills |

| Magnetic switch sensor | Control/sensing (no product contact) | Reliable position sensing; non‑wetted | Verify materials for environment (humidity); no product contact | Ambient | — | All models; confirm electrical/IP ratings |

| Electropolish (upgrade) | Surface finish upgrade | Improved cleanability; reduced micro‑crevices; enhanced corrosion resistance | Additional cost; confirm supplier certs and process | — | Supports hygienic requirements | Hygienic, chemical, or high‑frequency cleaning environments |

Notes and assumptions

– Elastomer temperature ranges are typical values; actual service limits depend on compound grade and compression. Always consult elastomer data sheets and validate with your product and cleaning chemistries.

– D8 rubber and Type B spider gasket materials follow common industry elastomer selections (NBR/EPDM); confirm grade with your supplier to match product and cleaning agents.

– For models without explicit finish specification, assume standard machine finish; upgrade to electropolish or RA specifications for stringent hygienic applications.

Action checklist

– Match elastomers to product chemistry and cleaning regime (oils vs steam vs solvents).

– Specify 316 SS for all product-contact wetted parts; use 304 SS for non-contact structure.

– Select non-drip nozzle tips sized for your particulates; validate spider gasket type.

– Request compliance documents (FDA/EU) for all elastomers used in product-contact service.

– If available, choose electropolish for aggressive CIP/SIP or high particulate abrasion environments.

– Document sanitation SOPs (CIP/SIP) and gasket inspection/replacement intervals.

Illustrative Image (Source: Google Search)

In-depth Look: Manufacturing Processes and Quality Assurance for viscosity filling machine

In-depth Look: Manufacturing Processes and Quality Assurance for Viscosity Filling Machines

This section examines how high-viscosity tabletop piston fillers, such as the E-FP-500-D (500 ml, 316 SS contact parts, 304 SS shell) are manufactured and controlled to meet industrial performance, hygiene, and regulatory expectations across the USA and Europe.

Manufacturing Process Overview

A typical production flow combines precision machining, hygienic finishing, pneumatic and electronic assembly, rigorous testing, and full traceability. The emphasis on stainless steel construction (316 for product-contact; 304 for non-contact) and food-grade materials supports durability and sanitation.

- Preparation and Sourcing

- Material traceability and certification (heat-lot traceability for stainless steel).

- Pneumatic components rated for industrial environments; food-grade tubing for air and product lines.

- Nozzle designs optimized for anti-drip performance and large particulates.

- Electrical/control subassemblies selected to comply with USA/EU standards.

- Gaskets and seals (e.g., silicone, rubber) chosen for compatibility with viscous pastes, creams, and gels.

-

Compliance checks such as Proposition 65 labeling when required.

-

Forming and Machining

- CNC machining of piston/cylinder assemblies, manifold blocks, nozzle bodies.

- Deburring, cleaning, and passivation of stainless steel components for corrosion resistance.

- Hygienic surface finishes: 316 SS contact surfaces typically finished to Ra ≤ 0.8 µm; non-contact surfaces to Ra ≤ 3.2 µm.

-

Inspection of critical dimensions and sealing interfaces prior to assembly.

-

Assembly

- Staged assembly: drive and transmission units; product-contact block; nozzle and drip-tip; pneumatic valves and lines.

- Integration of foot-activation circuitry and sensor (e.g., magnetic switch) for cycle feedback.

- Installation of gaskets/seals (silicone, rubber) and alignment verification of the piston/cylinder interface.

- Routing and secure mounting of tubing and fittings; check for strain relief and leak-free joints.

-

Application of labels and safety markings consistent with regional regulations.

-

Verification and QC

- Leak testing of pneumatic lines and seals; verification of anti-drip nozzle performance with viscous products.

- Volumetric accuracy and repeatability testing over target fill ranges.

- Electrical/functional testing of foot-pedal actuation and safety interlocks.

-

Documentation of calibration and inspection results; release to packaging/shipment.

-

Packaging and Documentation

- Protective packaging for transport and bench placement; inclusion of user instructions, maintenance/sanitation guidance, and parts listings.

- Traceability records and certificates for shipment.

Quality Assurance Standards and Practices

Manufacturing quality is governed by international standards that cover process control, safety, and hygiene. A concise framework aligns common requirements between USA and Europe.

Standards matrix: Scope and regional alignment

| Standard | Scope | USA/EU Applicability |

|---|---|---|

| ISO 9001 | Quality management systems; process control, documentation, traceability. | Widely adopted; used by equipment manufacturers globally. |

| ISO 14001 | Environmental management systems; resource use, waste, emissions control. | Common requirement for industrial OEMs; aligns with EU sustainability objectives. |

| ISO 45001 | Occupational health and safety; risk assessment and controls. | Adopted by manufacturers serving USA/EU; supports OSHA/HSWA compliance. |

| ISO 12100 | Machinery safety; hazard analysis, risk reduction, guard design. | Harmonized in Europe via EN ISO 12100; widely referenced in the USA for machinery safety. |

| ISO 13849-1 | Safety-related parts of control systems; performance levels (PL). | Harmonized in Europe; referenced in USA for functional safety design verification. |

| ISO 13485 | Quality management for medical devices (where applicable). | EU MDR compliance; USA manufacturers supplying medical markets. |

| EHEDG | Hygienic design for equipment; cleaning-in-place (CIP) suitability. | Widely referenced in Europe; increasingly adopted in USA for food/pharma processing. |

| ISO 14644 | Cleanliness classification for controlled environments; when relevant to contamination control. | Used globally; aligns with EU cleanroom requirements and many USA operations. |

| NIST SRM | Calibration traceability; metrological references. | USA standard; global relevance for calibration integrity. |

How quality controls apply to the tabletop piston filler

- Material control and sanitation

- 316 SS contact parts ensure corrosion resistance for viscous and particulate products; 304 SS shell provides structural strength.

-

Finish and passivation meet hygienic requirements; design supports easy sanitation with minimal tooling.

Illustrative Image (Source: Google Search)

-

Pneumatic integrity and anti-drip performance

- Leak testing and seal integrity checks ensure consistent actuation and prevent product waste.

-

Anti-leak nozzle and drip tip reduce mess, supporting clean bench environments.

-

Volumetric accuracy and measurement control

- Highly accurate volumetric filling supported by precision piston/cylinder design; measurement systems traced to calibration standards.

-

Repeatability validated across targeted viscosity and product ranges.

Illustrative Image (Source: Google Search)

-

Foot-activation and electrical safety

-

Interlock and sensor integration verified per functional safety practices; labels and warnings include Proposition 65 notices when required.

-

Documentation and traceability

- Datasheets, drawings, parts lists, inspection records, and calibration certificates support audits and customer requirements in both regions.

Manufacturing and QA Table: Steps, controls, and standards

| Manufacturing Step | Key QC Controls | Standards / References |

|---|---|---|

| Material sourcing and certification | Heat-lot traceability; stainless steel grade verification; gasket/seal compatibility | ISO 9001; SRM traceability (USA) |

| Machining and passivation | Dimensional inspection; surface finish and passivation verification | ISO 9001; EHEDG for hygienic surfaces |

| Assembly | Seal installation; pneumatic line integrity; nozzle anti-drip test; alignment checks | ISO 9001; ISO 12100 (hazard analysis) |

| Functional testing | Foot-pedal actuation; sensor response; leak checks; cycle timing verification | ISO 9001; ISO 13849-1 (functional safety) |

| Performance testing | Volumetric accuracy; repeatability; speed vs. consistency validation | ISO 9001; SRM calibration traceability |

| Documentation and release | Inspection/test reports; calibration certificates; labeling (Prop 65) | ISO 9001; regional labeling requirements |

| Packaging and shipment | Protective packaging; transport protection; parts list and manuals | ISO 9001; customer-specific requirements |

Regional considerations

- USA

- Calibration traceability commonly references NIST SRM; OSHA alignment supports occupational safety.

-

Proposition 65 warnings included on product documentation when applicable.

Illustrative Image (Source: Google Search)

-

Europe

- Machinery safety harmonized under EN ISO 12100; CE-marking practices for equipment safety.

- Hygienic design expectations strongly influenced by EHEDG guidance; environmental management per ISO 14001 is common.

Sanitation and maintenance compatibility

- Food-grade contact parts (316 SS), combined with smooth, polished surfaces, facilitate sanitation and reduce downtime.

- Foot activation minimizes operator contact with moving components; clean design supports routine sanitation cycles without tools.

- Anti-leak nozzle and drip tip help maintain clean work surfaces, supporting compliance with hygiene protocols.

What this means for buyers

- High-viscosity tabletop piston fillers, when manufactured to these processes and quality standards, deliver repeatable accuracy, robust hygiene, and dependable operation for viscous pastes, creams, lotions, gels, and products with large particulates.

- Documentation and traceability enable efficient validation, audits, and regulatory alignment in both the USA and Europe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘viscosity filling machine’

Practical Sourcing Guide: A Step-by-Step Checklist for a Viscosity Filling Machine

Key takeaways:

– Define your process upfront (product rheology, container/closure, throughput, cleanliness) before evaluating machines.

– Match technology to viscosity and particulates: piston, peristaltic, or gear pump; pressure/weight filling for thin liquids.

– Confirm materials of construction, sanitary design, and certification path (e.g., FDA, CE/UKCA) based on your use case.

– Verify accuracy, repeatability, nozzle/no-drip features, and clean-in-place/clean-out-of-place compatibility.

– Check utilities, integration needs, training, documentation, and spare parts support.

– Use a structured RFQ and evaluate TCO, not just upfront price.

Step 1: Define Your Process and Use Case

- Product profile:

- Viscosity range (mPa·s or cP), shear-thinning behavior, particle size/max particle.

- Temperature during filling; thixotropy/backpressure sensitivity.

- Abrasiveness or chemical aggressiveness (pH, solvents).

- Sanitary classification: food/beverage, pharma/cosmetics, industrial; cleaning requirements (CIP/SIP/COP).

- Packaging profile:

- Container type/material (HDPE, glass), neck finish, stability, fill volume range, changeover range, drip/trickle risk.

- Closure type (screw cap, snap-on), application timing and method.

- Performance targets:

- Target throughput (units/min), acceptable fill cycle time and yield/accuracy specs.

- Production uptime target (OEE), changeover time (SPC/quick nozzles).

- Environment:

- Power/air availability, floor space, washdown environment, ambient temperature.

- Regulatory context (USA/EU/UK): FDA 21 CFR, EHEDG/3-A optional for hygienic lines; CE/UKCA marking for EU/UK.

- Budget and timeline:

- Purchase price range, desired delivery and acceptance timeline.

- Service coverage (USA/Europe), spare parts stock, local support.

Step 2: Choose the Right Filling Technology

- High-viscosity/with particulates:

- Piston (per-stroke volume): best for paste/cream/chunky products; adjustable, repeatable volumes; handles larger particulates.

- Gear pump: smooth output with fine particulates; good for long hoses; check wear on abrasive products.

- Moderate viscosity, sterile/frequent cleaning:

- Peristaltic: sterile path, easy to clean, no valves; limited to lower viscosity and limited particulates.

- Low-to-medium viscosity:

- Pressure/time-pressure: precise for bottles using fill level probes or time; great for clean liquids.

- Weight/dynamic gravimetric: highest accuracy for sensitive formulas; slower and more expensive.

- Semi-viscous (lotion/gel):

- Piston or gear pump; consider nozzle drip control and anti-suck-back to avoid stringing.

Technology-to-material matrix (quick guide):

| Viscosity range | Particulates | Recommended technology | Why | Notes |

|---|---|---|---|---|

| High (paste/cream) | Small–medium | Piston | High accuracy, adjustable stroke, handles chunks | Strong CIP/SIP if hygienic; nozzle drip control critical |

| High with abrasives | Small–medium | Gear pump (hardened) | Smooth flow; less cavitation | Hardened shafts/seals to reduce wear |

| Moderate | None–minimal | Peristaltic | Sterile path, minimal contamination risk | Limited viscosity; verify hose material compatibility |

| Low–medium | None | Pressure/time-pressure | Fast, precise, bottle-oriented | Ideal for clean-room/beverage lines |

| Any | — | Gravimetric (weight) | Highest accuracy | Longer cycle time; larger footprint |

Step 3: Pre-Selection: Machine Specs and Features to Validate

- Materials and sanitary design:

- Product contact: 316 stainless steel; enclosure: 304 SS. Polished surfaces (≤32 Ra typical for food contact), crevice-free components.

- Connection standards: sanitary clamps (e.g., Tri-Clamp sizes), gasket materials (silicone, EPDM, Viton), compliance with FDA/EU food-contact regs.

- Filling control:

- Volumetric piston stroke adjustment; accurate fill repeatability (e.g., ±1% typical target, verify in RFQ).

- Anti-drip/no-drip nozzle, adjustable nozzle height, anti-suck-back valve, pre-compression control for paste products.

- Gentle start/stop controls to prevent splatter/air entrainment.

- Safety and hygiene:

- Interlocked guards, emergency stops, stainless construction, food-safe lubricants.

- Washdown-rated IP/chemical-resistant finish for hygienic cleaning.

- Usability:

- Foot pedal activation or automatic cycle; recipe recall/operator interface; quick-change nozzles; tool-less disassembly.

- Training and documentation: operator manual, maintenance procedures, spare parts list, wiring/P&IDs, CE/UKCA/Declaration of Conformity (DoC).

- Utilities:

- Compressed air (CFM, pressure) requirements for pneumatic units; electrical (VAC/Hz, amps) for automation; grounding.

- Portability and footprint:

- Compact tabletop design (e.g., 500ml tabletop piston filler) vs floor-mounted; wheels/leveling; height adjusters for different containers.

Checklist (spec verification):

| Spec | Required/Preferred | Target/Acceptance criteria | Notes |

|---|---|---|---|

| Contact materials | Required | 316 SS product contact; 304 SS enclosure | Confirm gasket/seal materials for chemical compatibility |

| Accuracy/repeatability | Preferred | ±1% or better on target volume | Ask for sample test results or demo |

| Viscosity capacity | Required | Confirmed for your product | Include temperature and shear conditions |

| Nozzle type | Preferred | Anti-drip/no-drip, adjustable | Consider quick-change kits |

| Sanitary design | Required | 3-A/EHEDG or equivalent where applicable | Otherwise meet hygienic design practices |

| CIP/SIP/COP | Preferred | Cleanable with standard procedures | Confirm seal/gasket compatibility |

| Control type | Preferred | Foot pedal/auto; recipes | Operator training implications |

| Air/electrical | Required | Verified to site conditions | Include CFM and load profiles |

| Documentation | Required | Manual, DoC, schematics | For QA/regulatory audits |

| Spare parts | Preferred | Stocked consumables and seals | Regional support in USA/EU |

Step 4: Sanitation and Compliance Alignment

- Food/beverage/pharma:

- FDA 21 CFR for food contact surfaces; 3-A/EHEDG optional for hygienic systems.

- EU: 1935/2004 (food contact materials) and 10/2011 (plastic materials) for applicable materials; CE/UKCA marking for machinery.

- Cleaning and validation:

- CIP/SIP feasibility: verify gasket/valve and diaphragm materials; confirm dead-leg minimization and crevice-free design.

- COP: tool-less disassembly; surface finish appropriate for cleaning.

- Chemical resistance:

- Select gasket/nozzle materials compatible with your product and sanitizers (e.g., EPDM, Viton, PTFE).

- Risk and warnings:

- Some products may carry Proposition 65 warnings (USA) based on materials or environment; verify product contact surfaces and any coatings.

- Safety: stainless construction, guards, E-stop, clear lubrication points (food-safe where applicable).

Step 5: Pilot, Trial, and Sample Verification

- Sample runs:

- Run your product through the candidate machine; evaluate fill accuracy, repeatability, drip, foam, and stringing.

- Record cycle time, changeover speed, and cleaning time. Capture defects and scrap rates.

- Acceptance criteria (define before testing):

- Fill accuracy: within tolerance (e.g., ±1%) across full volume range.

- Throughput: meets target cycle time and units/min.

- Product integrity: no aeration, chunk integrity preserved, nozzle clogging-free.

- Cleaning: achieves defined cleanliness level within expected CIP/COP time.

- Scale-up:

- Test with representative containers and closures; confirm nozzle height/anti-drip settings at different line speeds.

Step 6: Request for Quotation (RFQ) Template and Evaluation

RFQ essentials:

– Product properties (viscosity, temperature, particulates), target volumes and tolerances, changeover ranges.

– Container specs (type, neck finish, stability) and closure approach.

– Environment (utilities, washdown), compliance (FDA/EU standards), cleaning method (CIP/SIP/COP).

– Performance requirements (units/min, uptime), documentation (DoC, manuals), warranty and service.

– Optional items (quick-change nozzles, spare seals/gaskets, spare parts kit, training).

– Delivery and installation expectations.

Example (illustrative): “500ml tabletop piston filler (316 SS contact), 304 SS enclosure; foot pedal control; adjustable stroke; nozzle for paste/cream; ≥±1% accuracy; CIP-compatible; DoC/CE/UKCA documentation; includes basic spare seals/gaskets; onsite training.”

TCO evaluation:

| Cost component | Example considerations | Action |

|---|---|---|

| Machine | Purchase price; options and accessories | Compare like-for-like; include nozzle kits |

| Spare parts | Seals/gaskets, sensors, tubing | Ensure local stocking and pricing |

| Consumables | Lubricants, filter elements, O-rings | Verify food-safe materials |

| Service | Startup, training, preventive maintenance | Confirm USA/EU coverage; response times |

| Utilities | Air compressor capacity, electricity | Model to line load; potential upgrades |

| Labor | Operator time, changeover | Estimate based on trial results |

| Downtime | Failure modes; spares at risk | Add contingency spares to proposal |

| Cleaning | CIP media/time; downtime cost | Include impact on OEE |

| Compliance | Certification fees; documentation | Verify DoC, manuals, schematics |

Step 7: Installation, Commissioning, and Start-Up

- Pre-installation:

- Confirm utilities, floor space, and access for maintenance.

- Review manuals and DoC; verify spare parts kit and training schedule.

- Commissioning:

- Functional test; calibration and recipe setup; safety checks (guards, E-stop).

- Run product validation; adjust nozzle drip and stroke; document settings.

- Acceptance:

- Formal acceptance per agreed criteria; sign-off on documentation and warranty terms.

Step 8: Operation, Maintenance, and Continuous Improvement

- Preventive maintenance:

- Daily: nozzle inspection, seal condition, air/electrical connections, drip checks.

- Weekly: lubrication (food-safe if applicable), tubing integrity, sensor/pedal function.

- Quarterly/annual: seal/gasket replacement, check calibration, inspect for wear (piston seals, pump gears).

- Spare parts planning:

- Keep critical seals/gaskets (e.g., 1.5″, 2″, 2.5″ sanitary gaskets, D8 rubber seals, Type B spider gaskets, non-drip tips) and tubing on hand.

- Sensor/magnetic switch spares; pneumatic fittings; O-rings; quick-disconnect fittings.

- Continuous improvement:

- Monitor cycle time and accuracy; optimize nozzle size and stroke for throughput.

- Track changeover speed; implement quick-change kits where beneficial.

Step 9: Practical Notes from the Field

- Piston fillers excel with chunky/pasty products but can cavitate with very long hoses; position product hopper close to cylinder.

- Anti-suck-back/no-drip features reduce waste and rework; verify at different fill heights.

- For products that string, reduce stroke speed and use nozzle designs with back-pressure control.

- CIP success depends on gasket materials and component geometry; validate cleaning times on your product and cleaning media.

Quick RFQ Prompt You Can Use

“Please quote a sanitary volumetric filler suitable for [product description: viscosity, particulates, temperature]. Target fill volume [range] with ±[X]% accuracy at [units/min]. Contact parts 316 SS, enclosure 304 SS. Include anti-drip nozzle, adjustable stroke, foot pedal or automatic control, CIP-compatible design. Provide DoC (CE/UKCA), manuals, wiring/P&IDs, recommended spare parts list (seals/gaskets), USA/EU service coverage, and training. Include delivery lead time and options: quick-change nozzles, spare parts kit, extended warranty.”

Illustrative Image (Source: Google Search)

Example Reference (for spec benchmarking)

500ml high-viscosity tabletop piston filler (316 SS product contact; 304 SS shell; compact; foot pedal actuation; adjustable stroke; anti-drip nozzle; CIP-friendly sanitary design; suitable for pastes/creams/gels with large particulates). Price, lead time, and certification details to be confirmed with supplier (include DoC/CE/UKCA, spare seals/gaskets, and service terms in proposal).

Bottom Line

Choose the filling technology that matches your product’s viscosity and particulate profile. Validate with on-site samples, confirm materials and sanitary compliance, and evaluate TCO—then lock in service and spare parts support. A disciplined, step-by-step approach reduces risk and ensures a smooth, compliant, and efficient operation.

Comprehensive Cost and Pricing Analysis for viscosity filling machine Sourcing

Comprehensive Cost and Pricing Analysis for Viscosity Filling Machine Sourcing

Use this framework to translate manufacturer list prices into true landed costs in the USA and Europe, and to position your commercial offer with confidence. The example below anchors the analysis to a High Viscosity Tabletop Paste Piston Filler (316 SS, 500 ml) at a representative list price of £2,874.

1) Reference Product and Pricing Snapshot

- Model: High Viscosity Tabletop Paste Piston Filler – 316 SS, 500 ml (Technopack, via JORES TECHNOLOGIES)

- Representative list price: £2,874.00

- Typical accessory note: 19 mm Dispensing Nozzle Assembly ~£385 (sold-out indicated in listing)

Use the total landed cost (TLC) framework to align quotes and pricing across vendors.

Illustrative Image (Source: Google Search)

2) Total Landed Cost Framework (USD)

For budget planning, treat £2,874 ≈ $3,700 (indicative spot-equivalent). A pragmatic split for a stainless steel piston filler:

| Cost Element | Estimated USD | Notes |

|---|---|---|

| Manufacturer materials (316 SS contact, 304 SS shell, valves, pistons, seals) | 1,100–1,500 | Material index can swing ±20% with nickel alloy prices. |

| Mechanical fabrication | 450–700 | Includes CNC machining and hardware. |

| Assembly and calibration | 250–400 | Manual setup + leak/no-load tests. |

| QA, documentation, and electrical/pneumatic components | 150–300 | Safety switches, tubing, fittings. |

| Packaging and crating | 70–120 | Foam and wood crate for transit. |

| Factory overhead and margin | 800–1,100 | Covers SG&A and profit. |

| Freight (USA domestic) | 50–120 | Parcel/LTL based on mass/dimensions. |

| Typical Range: Total Landed (USA) | 2,870–4,360 | Central estimate ≈ $3,700 |

- Optional: Add $50–150 for USA safety markings/labels if required.

3) Import to Europe: Duties, VAT, and Logistics

For imports from the USA (HS 8422.30.0000, trade agreement-dependent):

| Item | Typical Range | Notes |

|---|---|---|

| Import duty | 1.7–3.7% | Dependent on country, HS classification, and country-of-origin. |

| VAT (destination) | 19–27% | Levied on CIF + duty + VAT + fees. |

| Brokerage and customs entry | $150–300 | Includes brokerage, storage if any, and admin fees. |

| EU shipping | $100–250 | Cross-border distribution and last-mile to site. |

| Compliance costs (CE/UKCA as applicable) | $50–200 | Labels, documentation, and electrical compliance where relevant. |

| Contingency (exchange/variation) | 2–4% | FX volatility and cost deviations. |

Indicative Landed Cost (EU):

– Central estimate: $3,700 list + $100 freight + $120 duty + $1,100 VAT + $200 brokerage = ~$5,220

– Reasonable band: $4,900–$6,100 depending on destination, VAT rate, and freight mode

4) Labor Cost to Operate and Maintain

Labor typically dwarfs CapEx over multi-year ownership:

| Labor Element | Hourly Wage (USD, indicative) | Annual Hours (1-shift) | Annual Cost (USD) |

|---|---|---|---|

| Operator (floor operator) | $18–22 | 2,080 | $37,440–$45,760 |

| Maintenance tech (general) | $28–38 | 260 | $7,280–$9,880 |

| Sanitation labor (CIP/SIP or manual) | $20–25 | 260 | $5,200–$6,500 |

Takeaway: A $3,700 tabletop filler can equate to a single operator’s 1–2 months of cost. Even small improvements in uptime and changeover time reduce total cost of ownership (TCO).

5) Spares and Consumables Forecast (Year 1–3)

For stainless piston fillers with 316 SS product contact:

| Part/Gasket | Approx. Price | Typical Frequency | Annualized Cost |

|---|---|---|---|

| D8 Rubber Seal | £8 | 1–2/year | $10–20 |

| Type B Spider Gasket for nozzle | £13 | 1/year | $16 |

| Magnetic Switch Sensor AL-20R | £34 | Replace on failure | $0–35 |

| 1.5″ Silicone Gasket | £10 | 1/year | $12 |

| 3″ Silicone Sanitary Gasket | £10 | 1/year | $12 |

| 15.5 mm Non-Drip Tip | £11 | 1/year | $13 |

| 2″ Silicone Sanitary Gasket | £13 | 1/year | $16 |

| 2.5” Silicone Sanitary Gasket | £10 | 1/year | $12 |

| PU Pneumatic Tubing Roll (6×4 mm, 5 m) | £12 | Every 2–3 years | $4–6 |

| Adjustable Pneumatic Elbow Connector | £13 | Replace on wear | $0–13 |

| 19 mm Dispensing Nozzle Assembly | £385 | Consider as option if needed | $0–385 |

Practical approach: Establish a spares kit and inventory gasket sizes to avoid line stops. Where 316 SS contact parts are mandatory (dairy, specialty chemicals), prefer 316 SS hardware over elastomers where compatible.

6) Practical Cost Levers (Immediate Savings)

- Buy bundle, not piecemeal: A compact tabletop like the reference model eliminates the need for conveyors, hoppers, or integrated controls, which reduces CapEx and space.

- Optimize nozzle strategy: Choose a single nozzle size for a family of SKUs and tune via stroke/time. Larger diameter nozzles (e.g., 19 mm assemblies) reduce cycle time but raise part cost and risk splash/drip.

- Specify materials up-front: 316 SS for product contact often costs 10–20% more than 304 SS; clarify whether non-contact parts can be 304 SS to balance hygiene and cost.

- Foot-activation and simplicity: Manual actuation models need little training and minimal electrical certification overhead—lowering both CapEx and commissioning costs.

- Sanitation mode: Favor CIP/SIP-compatible wetted parts where cleaning time is high; otherwise, use simple disassembly with tool-free parts for low-CIP lines.

- Logistics optimization: Ship via domestic freight in the USA to avoid import duties/VAT and brokerage. For EU imports, combine shipments and ensure HS classification and country-of-origin documentation is complete to avoid storage fees.

- Spare parts kit: Pre-buy critical seals/gaskets to reduce downtime costs. Consider dual-size gasket kits if product portfolio spans orifice sizes.

7) Sourcing and Negotiation Tactics

- Quote comparability: Normalize to total landed cost (USA) or CIF + duty + VAT + brokerage (EU). Do not compare list prices alone.

- Warranty and lead-time: Request warranty terms, replacement lead times, and field service availability in-region. Faster service reduces lost production.

- Multi-quote sampling: Secure two to three quotes that match materials, nozzle count, cycle time, and sanitation standard. Ask for spares pricing explicitly to avoid “post-sale pricing” surprises.

8) How to Use This Framework

- Use the USA table to benchmark quotes and build your offer structure with realistic margins.

- Apply the EU table to land price offers in EUR or USD and quote ex-works vs delivered per Incoterms.

- Maintain a rolling labor utilization and downtime log to quantify payback from cycle-time or sanitation improvements.

Notes and assumptions:

– £–$ parity assumed for budgeting; final FX rate at time of quotation applies.

– Weight/dimensions affect freight bands; actual TLC varies by geography, HS duty, and VAT rate.

– Example product: High Viscosity Tabletop Paste Piston Filler – 316 SS, 500 ml, list £2,874; optional 19 mm nozzle assembly ~£385.

– California Proposition 65 warnings may require labeling changes or material substitutions if sold into that market.

Illustrative Image (Source: Google Search)

Alternatives Analysis: Comparing viscosity filling machine With Other Solutions

Alternatives Analysis: Comparing viscosity filling machines with other solutions

Executive summary: For thick pastes, creams, gels, and products with large particulates, piston-based viscosity fillers deliver the best balance of accuracy, cleanability, and sanitary design. Peristaltic fillers excel for shear‑sensitive and abrasive products but often struggle with very high viscosities and large particles. Progressive cavity fillers handle the highest viscosities and abrasives but are more complex to CIP/SIP, heavier, and costlier.

Feature comparison: viscosity piston filler vs peristaltic vs progressive cavity

| Attribute | Viscosity Piston Filler (tabletop 316 SS, 500 ml example) | Peristaltic Pump Filler | Progressive Cavity Pump Filler |

|---|---|---|---|

| Typical viscosity range | High; pastes, creams, lotions, gels; handles products with large particulates | Low to medium‑high; not suited to very high viscosities or large particles | Very high to paste; excellent for abrasive, chunky products |

| Fill accuracy | High volumetric repeatability | Good, best in low‑to‑medium viscosity ranges | Good to fair; can vary with pressure and backflow |

| Cleanability (CIP/SIP) | Simple; 316 SS contact parts; tool‑free disassembly; easy to sanitize | Simple circuit; tube is disposable or quick to replace | Complex internals; cleaning is harder and耗时 |

| Particulate tolerance | Strong (nozzle designs available; anti‑drip) | Limited; soft tube may deform | Strong |

| Shear sensitivity | Low (direct displacement) | Good (gentle peristaltic action) | Moderate (pumping can generate shear) |

| Sanitary design | Food‑grade contact parts; stainless steel; foot activation options | Hygienic; tube as consumable; fewer dead legs | Sanitary options exist but more internals |

| Maintenance | Moderate; seals/gaskets common replacement items | Low to moderate; tube replacement; limited moving parts | Higher; rotor/stator wear; seals |

| Cost/footprint | Entry‑level: compact, smaller CAPEX footprint | Moderate CAPEX; compact | Higher CAPEX; larger footprint |

| Speed potential | Medium; improves product output; pedal actuation | Medium; speed limited by tubing and flow | High; efficient for heavy pastes, but setup complexity rises |

| Material of construction | 316 SS contact parts; 304 SS shell | 316 SS housing; tubing material defines contact | 316 SS; elastomers for stator/rotor |

| Use case fit | Entry‑level viscous filling; small/medium runs; easy to sanitize | Shear‑sensitive products, cleanroom/biotech, low‑viscosity pastes | Highly viscous, abrasive, chunky products; heavy‑duty lines |

Practical scenarios and decision guidance

- Choose viscosity piston filler when:

- You are filling thick pastes, creams, gels, or products with particulates up to large sizes.

- Accuracy and sanitation are top priorities, and you need quick changeover with minimal tooling.

- You prefer compact equipment with an easy-to-clean, 316 SS food‑grade design.

-

You want entry‑level, intuitive operation with repeatable results and anti‑drip dispensing.

-

Choose peristaltic filler when:

- The product is shear‑sensitive or sterile‑oriented and requires gentle handling.

- Fill volumes are small to medium with low or moderately viscous liquids, and tube replacement simplifies validation.

-

You need rapid changeovers with minimal equipment cleaning between products.

-

Choose progressive cavity filler when:

- The product is extremely viscous, abrasive, or includes large, hard particulates.

- Your process demands high throughput on continuous duty and can accommodate heavier equipment.

- You accept higher CAPEX and longer cleaning cycles for the capability to handle severe pastes.

Buying notes (US/EU audience)

- Sanitation and certification: Confirm 316 SS contact parts, hygienic clamp connections (Tri‑Clamp/ASME BPE), and CE/UL conformity as needed.

- Spare parts availability: Ensure seals/gaskets, gaskets, nozzles, and sensors (e.g., magnetic switch sensors) are locally supported.

- Pneumatics: Confirm valve sizing and air quality to match the chosen platform; plan for clean, dry air in GMP environments.

- Total cost of ownership: For piston fillers, typical spare items are seals, gaskets, and nozzles; for peristaltic, tubing is a consumable; for progressive cavity, rotor/stator wear parts drive higher maintenance cost.

Essential Technical Properties and Trade Terminology for viscosity filling machine

Essential Technical Properties and Trade Terminology for Viscosity Filling Machines

Key take-aways

– Target high-viscosity, paste and chunky products with 316 stainless steel contact parts and a 304 stainless shell; an anti-drip nozzle and foot activation simplify operations and sanitation.

– Choose a volumetric piston filler for precise, repeatable fill volumes; pay attention to viscosity range, particulate size compatibility, and batch-to-batch repeatability.

– Specify accuracy as volumetric repeatability at target viscosity; use fill-weight variance bands for QC and reject-rate control.

– Confirm sanitation standards (FDA/EU 1935/2004 for food contact), pneumatic safety (CE/UKCA/UL), sanitizing ease, and any Prop 65 labeling requirements for California deliveries.

– Negotiate trade terms: MOQ, lead time, packing/shipping (Incoterms), validation support (IQ/OQ/PQ), warranty, spare parts, and on-site commissioning.

Core technical properties that define a viscous filling machine

High-viscosity paste piston fillers are designed for accuracy, easy cleaning, and reliable performance with thick, non‑Newtonian materials. Representative models in this class, such as the E-FP-500-D (316 SS contact), use 316 stainless steel parts in contact with product, a 304 stainless steel shell, foot activation, and an anti-leak nozzle to reduce waste and improve consistency. Typical applications include pastes, creams, lotions, gels, and products with large particulates.

- Viscosity handling and materials: Piston fillers handle high viscosities effectively; 316 stainless steel (SS) product-contact parts improve corrosion resistance and support sanitary conditions, especially for acidic/salty formulations. 304 SS shells support durability.

- Nozzle and drip control: Anti-leak/no-drip nozzle technology helps minimize product waste and mess. Nozzle orifices must match particulate size; choose interchangeable assemblies to change tips without tools when possible.

- Accuracy and repeatability: Volumetric fillers are precise for highly viscous products, but batch-to-batch repeatability depends on viscosity fluctuations, piston/seal condition, and nozzle size. Specify “repeatability as % of target volume at target viscosity.”

- Dosing control and changeover: Adjustable dosing lets operators set fill volumes per stroke or per program. Fast, tool‑free changeover reduces downtime for product switches.

- Pneumatic operation and safety: Pneumatic systems are typical in paste fillers. Specify air pressure requirements and filtration; confirm compliance with applicable pneumatic safety standards (CE/UKCA/UL) and the Machinery Directive (EU).

- Sanitation and sealing: Food‑grade contact materials (e.g., 316 SS) and silicone/PTFE seals/gaskets support cleaning. Simple disassembly and tool‑free maintenance reduce cleaning time and contamination risk.

- Operator interface and actuation: Simple controls and foot pedals improve ergonomics and throughput; intuitive interfaces minimize training time.

- Mounting and footprint: Compact tabletop units fit standard benches; consider vibration isolation and height adjustments for containers.

Critical specifications and compliance

- Materials: Product-contact parts often use 316 SS; shells may be 304 SS. Acceptable seal/gasket elastomers include silicone and EPDM; PTFE for some seals. Confirm compatibility with formulation pH, salts, and cleaning agents.

- Food/chemical safety: For food-contact applications, ensure compliance with FDA (USA) and EU Regulation 1935/2004 (Europe) on materials in contact with food. Check Prop 65 requirements for shipments to California, as many suppliers include Prop 65 statements when applicable.

Property-to-impact summary

| Property | What to specify | Why it matters | Typical trade impact |

|---|---|---|---|

| Viscosity range | cP (or mPa·s), temperature at measurement | Determines suitability for product; accuracy at stated viscosity | Models outside range require different pump type |

| Particulate compatibility | Max particle size vs nozzle bore | Avoids clogging and breakage; controls shear | Dedicated nozzle set needed |

| Dosing range | ml/oz per stroke; min–max | Ensures usable fill envelope for containers | Tool changeovers impact setup time |

| Accuracy/repeatability | % of target at viscosity, RSD or Cpk | Controls giveaway/underfill and rejects | Tight specs can increase unit cost |

| Nozzle type | Anti‑drip/no‑drip, interchangeability | Reduces waste; faster changeovers | Specialized nozzles add spares cost |

| Materials | 316 SS contact; gasket type | Chemical resistance; cleanability | Higher‑grade SS may affect price |

| Pneumatics | Air pressure/filtration | Stable cycles; safety compliance | Additional FRL unit cost |

| Sanitation | Tool‑free disassembly | CIP/SIP compatibility, downtime | More parts to validate and stock |

| Foot activation | Yes/No; remote | Operator ergonomics | Safety circuits may be needed |

| Electrical/pneumatic safety | CE/UKCA/UL; Machinery Directive | Market acceptance; risk mitigation | Additional certification costs |

| Dimensions/weight | W x D x H; kg/lb | Fit to line; shipping class | Freight and install planning |

Trade terms and commercial definitions used in viscous filling machines

| Term | Definition | Notes for USA/Europe |

|---|---|---|

| MOQ (Minimum Order Quantity) | Lowest quantity a supplier will accept per order/model | Common for OEM and custom builds; confirm spares MOQs |

| OEM (Original Equipment Manufacturer) | Manufacturer provides machines branded by reseller | OEM models may differ slightly; confirm exact spec |

| Lead time | Time from PO to shipment | Paste fillers often 2–6 weeks depending on configuration |

| Incoterms (e.g., EXW, FOB, CIF, DDP) | Risk/cost split for shipping | USA: common FOB/FCA; Europe: often CIF or EXW |

| L/T (Lead Time) | See above | Used in production planning |

| T/T, L/C, Net terms | Payment methods | T/T common; Net 30 may require credit approval |

| FOB/FCA | Point where risk transfers from seller to buyer | Clarify port/airport; packaging/crating charges |

| Warranty | Coverage period and scope | Often 12–24 months; exclude wear items |

| IQ/OQ/PQ (Installation/Operational/Performance Qualification) | Validation protocol support | FDA/EU GMP compliance; request documentation |

| CIP/SIP | Clean‑in‑Place / Sterilize‑in‑Place | Validate gasket/seal compatibility and drains |

| Spare parts / consumables | Recommended spares, wear parts | Keep pistons, seals, gaskets in stock; confirm part numbers |

| On‑site commissioning | Engineer visit for setup | Useful for complex lines; budget travel costs |

| Training | Operator and maintenance training | Reduces downtime; may be included with commissioning |

| Documentation | Manuals, P&ID, BOM, electrical schematics | Supports maintenance, safety, and audits |

| Certifications | CE/UKCA/UL; food compliance | Required for market entry; attach to PO |

| Prop 65 | California labeling requirement | If applicable, include labels and warnings in shipment |

Practical selection notes

- Confirm viscosity at processing temperature and particle size; match nozzle bore accordingly.

- Set acceptance criteria as volumetric repeatability at target viscosity (e.g., ±0.5–1.0% for many pastes).

- Choose anti‑drip nozzles to reduce waste; specify materials compatible with formulation and cleaning agents.

- Ensure all product‑contact parts are food‑grade (e.g., 316 SS contact, silicone/EPDM gaskets).

- For pneumatic models, specify air quality and safety interlocks; confirm CE/UKCA/UL compliance.

- Ask for IQ/OQ/PQ protocols and sanitation schematics; plan tool‑free changeovers to minimize downtime.

Checklist to include in your RFQ

- Product viscosity (cP) and temperature; max particle size

- Target container range (min/max volume) and fill accuracy specification

- Nozzle requirements (anti‑drip; exchangeable tips; size range)

- Materials and seals (316 SS contact; gasket type)

- Sanitation requirements (CIP/SIP; cleaning agents; disassembly)

- Actuation and control (foot pedal; timer; cycle rate)

- Pneumatic/electrical specs; safety compliance (CE/UKCA/UL)

- Validation and documentation (IQ/OQ/PQ; manuals; BOM; schematics)

- Trade terms (MOQ; lead time; Incoterms; warranty; commissioning; spares; training)

Summary: For high‑viscosity filling, prioritize a volumetric piston filler with 316 SS contact parts, 304 SS shell, anti‑drip nozzle, and intuitive actuation. Specify accuracy, repeatability, particulate compatibility, and sanitation needs; confirm FDA/EU food compliance, pneumatic safety certifications, and any Prop 65 labeling. Secure clear trade terms—MOQ, lead time, Incoterms, warranty, spares, and commissioning support—to align expectations and ensure a smooth deployment across USA and Europe.

Illustrative Image (Source: Google Search)

Navigating Market Dynamics and Sourcing Trends in the viscosity filling machine Sector

Navigating Market Dynamics and Sourcing Trends in the Viscosity Filling Machine Sector

Drivers shaping demand

- Shortening of product lifecycles and SKU proliferation compress time-to-changeover; flexible tabletop piston fillers and modular platforms gain share.

- Line integration is accelerating: buyers expect plug-and-play control options (foot switch, digital presets, basic PLC integration) and hygienic designs that slot into CIP/SIP processes.

- Sustainability and total cost of ownership (TCO) are now core purchasing criteria; stainless steel contact parts, re-useable components, and service-friendly designs reduce waste and lifecycle cost.

- Supply chain volatility increases risk: longer lead times, component constraints (gaskets, sensors), and price pressure encourage vendor diversification and spare parts standardization.

Segment snapshot: tabletop piston fillers (entry to mid-volume)

- Typical applications: creams, lotions, pastes, gels, sauces, and products with large particulates.

- Core performance levers: volumetric accuracy, anti-drip/no-drip nozzle control, foot activation, adjustment range for volume and dwell, sanitary gaskets (FDA/EU 10/2011 compliant materials).

- Typical materials: 316L stainless steel for product contact, 304 stainless for non-contact; sanitary gaskets (e.g., silicone, EPDM) sized to sanitary standards (e.g., 1.5″, 2″, 2.5″, 3″).

- Controls/connectivity: common PLC protocols, IO-Link, Ethernet/IP; remote diagnostics increasingly requested in Europe.

- Compliance/regulatory: US buyers prioritize FDA contact materials and cUL/UL for electrical; EU buyers emphasize CE marking, conformity with EU Food Contact Material Regulation (EU 10/2011), and, in some cases, 3‑A SSI/EHEDG where sanitary design standards are mandated.

USA vs EU: sourcing differences and what to watch

| Topic | USA | EU |

|---|---|---|

| Regulatory posture | FDA for food-contact surfaces; cUL/UL for electrical; Proposition 65 labeling for certain states | CE mark; EU 10/2011 food-contact compliance; REACH restrictions; sanitation certifications valued in food/pharma |

| Supplier preference | Mix of domestic and imported lines; short installation windows; strong expectation for rapid service | EU/UK/EFTA plus imported lines; greater emphasis on sanitary standards and certification documentation |

| Service expectations | High availability of spares; fast on-site response; modular training for operators | Strong preference for remote support; strict documentation (EC Declaration of Conformity, technical files) |

| Integration | PLC connectivity and IO common; adoption of IIoT rising | Broad adoption of Industry 4.0 features; standardized IO-Link/Ethernet for diagnostics |

| Cost/TCO lens | Capex sensitivity, strong ROI focus; acceptance of remanufactured/refurb units | Total lifecycle and compliance bundled; longer-term service contracts more common |

| Sustainability emphasis | Increasing adoption of stainless platforms with repairable parts | Strong sustainability mandate; documentation and green certifications impact procurement scoring |

Sustainability practices that impact procurement decisions

- Hygienic stainless steel platforms (316L wetted parts, 304 non-wetted) reduce changeover risk and enable CIP/SIP.

- Standardized sanitary gaskets and spare parts minimize inventory and reduce waste from oversized stocking.

- Repairable assemblies (e.g., nozzle tip kits, gasket sets) extend service life and support OEM/aftermarket balance.

- Energy-efficient pneumatic actuation and optimized dosing reduce air consumption and cycle time.

- Documentation practices (compliance certificates, material traceability) shorten audits and mitigate risk for regulated markets.

Technology and application trends

| Trend | Implication for sourcing |

|---|---|

| Volumetric piston fillers for viscous and chunky products | Specify nozzle size, dwell profile, and anti-drip control to manage particulates without shear |

| Sanitary gaskets and 3‑piece nozzles | Support faster cleaning; choose FDA/EU-compliant materials for cross-region compliance |

| Compact tabletop footprint | Fit lines with limited floor space; consider bench-loading and ergonomic height |

| Foot activation and plug-and-play I/O | Improve operator throughput and reduce training time |

| Modular digital presets | Enable SKU switching with fewer changeovers; specify clear memory/recall and lockout features |

| Remote diagnostics (EU-leaning) | Plan for connectivity options and service contracts for faster issue resolution |

| Servo/gravity hybrid platforms (mid/high volume) | When throughput matters, specify servo dosing to improve accuracy and reduce waste |

Practical supplier questions and evaluation checklist

- Materials and compliance

- Confirm 316L stainless steel contact parts; request material traceability certificates.

- Verify FDA 21 CFR/EU 10/2011 compliance of elastomers; list gasket material variants (EPDM, silicone, FKM).

- Sanitary design and CIP/SIP

- Ask for hygienic nozzle design (sanitary tri-clamp options), dead-leg minimization, and optional CIP capability.

- Check sealing and nozzle tip kits; identify compatible gasket sizes (1.5″, 2″, 2.5″, 3″).

- Controls and connectivity

- Determine compatibility with your PLC and IO requirements; confirm foot switch support and safety interlocks.

- Evaluate digital presets and lockout settings; request communication protocol details (Ethernet/IP, PROFINET, IO-Link) if applicable.