Precision Welding Automation for Heavy Industry

High-capacity welding rotators, positioners, and manipulators engineered for wind towers, pipelines, pressure vessels, and offshore structures.

This page is not the official website. Generated by AI, does not constitute any advice. If needed, please click here to visit the corresponding official website.

High-capacity welding rotators, positioners, and manipulators engineered for wind towers, pipelines, pressure vessels, and offshore structures.

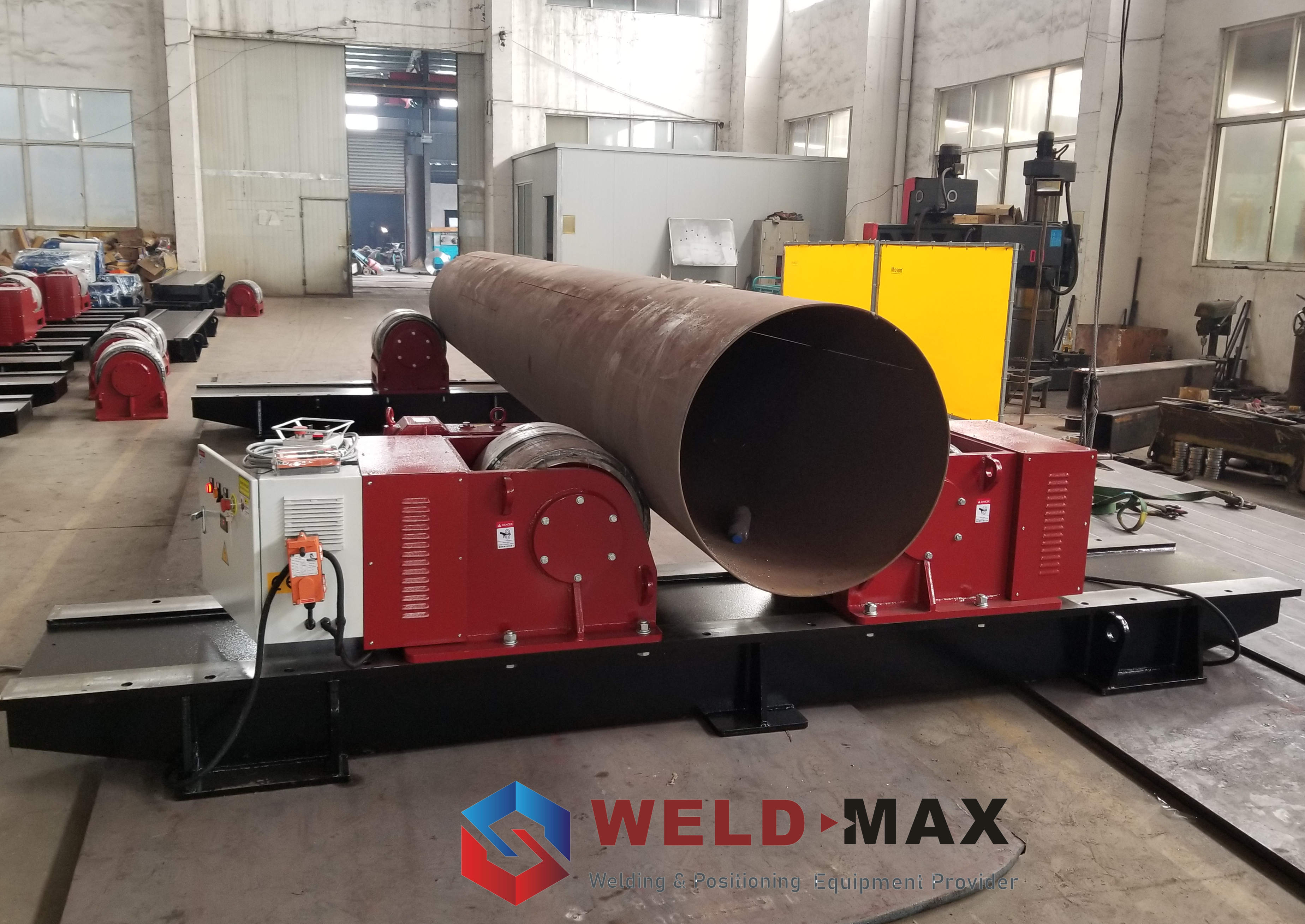

Sanlian, operating as Weld-Max, is a leading manufacturer of advanced welding automation equipment based in Wuxi, China. With decades of engineering expertise, we specialize in high-load welding rotators, positioners, and manipulators designed for the most demanding industrial environments.

Our products are trusted globally in sectors such as wind energy, oil & gas, shipbuilding, and heavy fabrication. From self-aligning rotators with 80-ton capacity to hydraulic lifting positioners, every machine is built for precision, durability, and seamless integration into automated production lines.

Max Load Capacity

Average Delivery Time

Engineered for reliability and performance in heavy fabrication, our welding automation systems enhance productivity and weld quality.

80-ton load capacity with PU wheels for smooth rotation and automatic alignment of cylindrical workpieces.

Headstock with hydraulic elevation for precise positioning of heavy workpieces during welding.

Tilting table design for accurate positioning of pipe fittings, elbows, and flanges.

Precision-guided welding head movement for longitudinal and circumferential seams on large structures.

Automated system for assembling and welding large-diameter pipes and wind tower sections.

Automated submerged arc welding system for H-beams and structural profiles.

High-precision cutting of steel plates for wind towers, pressure vessels, and structural components.

Complete automated solution for manufacturing wind turbine towers with integrated cutting, rolling, welding, and testing.

Our engineering excellence and global support network ensure maximum uptime and productivity.

ISO-certified manufacturing with rigorous testing at every stage.

Average 45-day delivery time with global sea and land logistics.

Installed in USA, Canada, Australia, Russia, Turkey, and more.

On-site installation, training, and 24/7 remote support available.

Our equipment is engineered for the most challenging industrial environments.

Complete production lines for tower sections with automated welding and handling.

High-precision rotators and positioners for ASME-certified vessel fabrication.

Fit-up growing lines and rotators for large-diameter pipe welding.

Heavy-duty systems for offshore platforms, subsea structures, and shipbuilding.

Request product brochures, pricing, or technical specifications directly from the manufacturer.

Weld-Max (Sanlian)

No.76 Liulv Rd, Binhu Dist, Wuxi, P.R. China 214000

Email: info@weld-max.com

Phone: 86-510-87052757

Fax: 86-510-87057518

Notice for Buyers: If you are a buyer, the above information is generated by AI collection and does not constitute any advice. If necessary, please visit the corresponding official website.

For Domain Owners: If you are the domain owner and do not want to be included by fobcompany.info, please contact support@fobcompany.info via your corporate email to cancel. We will cancel your inclusion within 3 business days.

如果您是域名所有者 不想被fobcompany.info收录 请用企业邮箱联系support@fobcompany.info 取消收录 我们将在3个工作日取消您的收录

Service Request: If you are other domain and want to be included, please contact support@fobcompany.info

如果您是其他域名合作 也请联系support@fobcompany.info