White Pvc Skirting Board: The Ultimate 2025 Sourcing Guide

Introduction: Navigating the Global Market for white PVC skirting board

Distributors, contractors, and facility managers in the USA and Europe seek base finishes that deliver speed, consistency, and low lifecycle cost. White PVC skirting board has become the default choice for projects ranging from commercial interiors to multi-unit residential programs where time-to-completion and minimal upkeep drive decisions.

Buyers face a recurring set of challenges: installers must achieve a uniform finish under tight schedules; maintenance teams need durable profiles that resist bumps and moisture; specifiers must balance lifecycle cost against upfront price; and procurement must ensure color consistency and technical compliance across regions.

This guide provides a structured, vendor-neutral framework to select, specify, and source white PVC skirting boards. It covers technical selection (core composition, thickness, and color matching), adhesives and installation methods, durability and maintenance, compliance and standards, and sourcing strategies for North American and European markets. We also incorporate practical guidance from professional-grade products—such as adhesive installation for fast fit-out, minimal post-installation care, and robust 16 mm profiles with skin-wrapped cores—so you can make confident decisions that reduce time, protect interiors, and deliver a clean, long-lasting finish.

Top 10 White Pvc Skirting Board Manufacturers & Suppliers List

1. Skirting Board Self-Adhesive PVC 100x25mm White

Domain: questprofile.com

Registered: 2017 (8 years)

Introduction: In stockFlexible self-adhesive PVC skirting board for surface finishing. Made of soft PVC. Available in pre-cut sections. Max roll length (m): 25…

2. PVC Skirting Boards – Raitto’s

Domain: raittoplastic.com

Registered: 2023 (2 years)

Introduction: Our company is one of the leading PVC skirting board manufacturers/suppliers. Our PVC skirting board has high quality and competitive price….

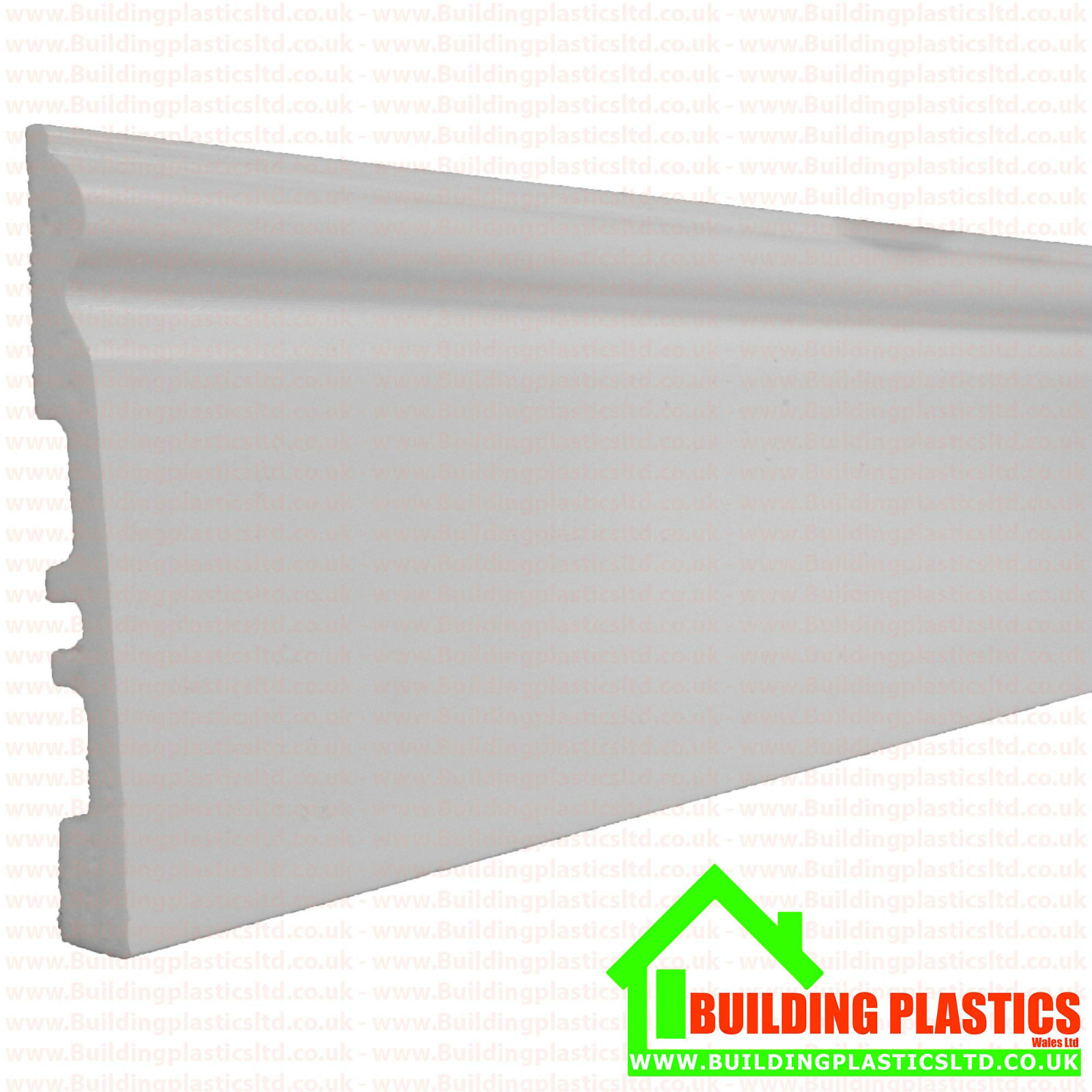

Illustrative Image (Source: Google Search)

3. PVC baseboard, PVC skirting – All architecture and design …

Domain: archiexpo.com

Registered: 2005 (20 years)

Introduction: Find your pvc baseboard easily amongst the 89 products from the leading brands (EMAC, profilpas, Tarkett, …) on ArchiExpo, the architecture and design ……

4. PVC Skirtings | Gerflor Professional

Domain: gerflorme.com

Registered: 2013 (12 years)

Introduction: Vinyl design skirting for a perfect finish of Gerflor floorcoverings. … Also available in paintable white; Extra thin (10mm); 100 % waterproof ……

5. pvc skirting board online manufacture

Domain: pvc-skirting.com

Registered: 2023 (2 years)

Introduction: Good quality pvc skirting board from pvc skirting board manufacturers, We sell pvc skirting board online from China….

6. PVC skirting board – Luxury vinyl flooring – VOX ceiling

Domain: voxindia.co

Registered: 2018 (7 years)

Introduction: Discover exquisite luxury vinyl flooring and PVC skirting board designs of unparalleled quality at VOX India. Elevate your space with our premium selection ……

Illustrative Image (Source: Google Search)

7. Custom Plastic White Skirting Boards Suppliers, Manufacturers

Domain: tiletrim.com

Registered: 2004 (21 years)

Introduction: As one of the most professional plastic white skirting boards manufacturers and suppliers in China, we’re featured by quality products and good service….

8. Skirting Board Manufacturer | PVC Tile Trim Supplier | Cheng Feng

Domain: plastic321.com

Registered: 2009 (16 years)

Introduction: We are a skirting board manufacturer and PVC tile trim supplier for more than 20 years. We produce a wide range of high quality vinyl tile edge trim….

Understanding white pvc skirting board Types and Variations

Understanding White PVC Skirting Board Types and Variations

White PVC skirting boards are available in distinct profile geometries, finishes, and installation methods. For USA and Europe-based B2B readers, the most relevant types align with common architectural detailing and practical installation workflows:

- Ogee (decorative double-bead) — a classic, high-detail profile.

- Chamfer/flat — a simple, modern edge with minimal detailing.

- Torus/ovolo — a convex, rounded profile that softens transitions.

- Bullnose — fully rounded face, often used for safety and minimalist detailing.

- Adhesive-only installation — surface-mounted, no mechanical fixing.

The table below summarises the key differences across type, features, common applications, and practical pros/cons. Specifications are based on Freefoam Building Products’ white PVC skirting boards, including their FOS range (ogee-shaped) and related white finishes.

Illustrative Image (Source: Google Search)

Type vs. Features vs. Applications vs. Pros/Cons

| Type | Core Features | Typical Applications | Pros / Cons |

|---|---|---|---|

| Ogee (FOS, 16 mm) | Decorative double-bead profile; solid PVC core and skin; White (RAL No. 9003); adhesive-only install (no nails/screws); low maintenance; suitable for repairs | Residential living spaces; hospitality corridors; commercial interiors requiring a classical detailing | Pro: high visual impact, easy post-fit wipe-clean finish, fast install (up to 50% time savings). Con: more complex profile may collect dust in high-traffic settings; typically 16 mm thickness (check site-specific tolerances). |

| Chamfer / Flat | Minimalist bevelled/flat face; solid PVC core and skin; White (RAL No. 9003); adhesive-only; low maintenance | Modern offices; retail; healthcare corridors; clean aesthetic zones | Pro: clean lines, easy to wipe; simple profile reduces dust build-up. Con: less decorative detailing; may feel plain in heritage/traditional projects. |

| Torus / Ovolo | Rounded convex bead; solid PVC core and skin; White (RAL No. 9003); adhesive-only; low maintenance | Schools; healthcare; hospitality; residential living areas with rounded edge preference | Pro: softened transition reduces chipping and improves safety; durable in frequent-use areas. Con: slightly more complex profiling than flat/chamfer; standard thickness typically 16 mm (verify per range). |

| Bullnose | Fully rounded face; solid PVC core and skin; White (RAL No. 9003); adhesive-only; low maintenance | Childcare facilities; hospitality; residential; areas where sharp edges are undesirable | Pro: safe, chip-resistant edge; fast wipe-clean maintenance. Con: minimal visual detailing; less contrast with walls; standard thickness typically 16 mm (verify per range). |

| Adhesive-Only Installation | Surfaces bonded with widely accessible adhesives; no nails/screws; paint-free finish; solid PVC core and skin; White (RAL No. 9003) | Fast-turn fit-outs; refurbishment; occupied spaces where drilling/noise is limited; retail and healthcare upgrades | Pro: up to 50% fitting time savings; reduced preparation and finishing; fit-and-forget material. Con: surface preparation quality drives performance; not ideal for very uneven substrates without rectification. |

Notes:

– Thickness: The Freefoam PVC skirting boards referenced are 16 mm thick (FOS range).

– Finish: White options are offered in RAL No. 9003. Freefoam notes that all RAL numbers are the nearest equivalent.

– Colours: Additional white-related finishes are available on related product lines (e.g., Matte Foil White, Agate Grey, and various woodgrain options). Confirm colour matching across skirting and adjacent trims on a project basis.

Detailed Type Descriptions

Ogee (FOS, 16 mm)

– Profile: Decorative ogee (double-bead) detailing commonly used to balance classical interiors with contemporary materials.

– Material: Solid PVC core and skin, 16 mm thickness; durable and impact-resistant; White (RAL No. 9003).

– Installation: Adhesive-only; no nails or screws; widely accessible adhesives reduce time and mess. Freefoam indicates up to 50% time savings compared to traditional mechanical fixing and finishing workflows.

– Maintenance: No sanding or painting; wipe-clean with a damp cloth; repainting is not necessary.

– Typical applications: Residential living rooms, hallways; hospitality corridors; commercial interiors where decorative profiles are specified.

– Considerations: Rich detailing can trap dust in very busy spaces; ensure adhesive compatibility with substrate and follow preparation guidance.

Chamfer / Flat

– Profile: Simple bevelled or flat face that delivers a clean, modern junction between wall and floor.

– Material: Solid PVC core and skin; 16 mm thickness (typical for Freefoam PVC skirting boards).

– Installation: Adhesive-only; quick to fit and finish.

– Maintenance: Minimal upkeep; easy to clean.

– Typical applications: Modern offices, retail back-of-house, healthcare corridors, and any environment where crisp, unobtrusive detailing is preferred.

– Considerations: Best suited to contemporary interiors; may look plain where detailing is expected.

Torus / Ovolo

– Profile: Convex, rounded bead; softens edges and reduces visible impact points.

– Material: Solid PVC core and skin; 16 mm thickness; White (RAL No. 9003).

– Installation: Adhesive-only; standard wipe-clean maintenance.

– Typical applications: Schools, hospitals, hospitality, and residential spaces where rounded detailing improves durability and safety.

– Considerations: Rounded faces can be advantageous in high-traffic areas; standard 16 mm thickness (confirm per product).

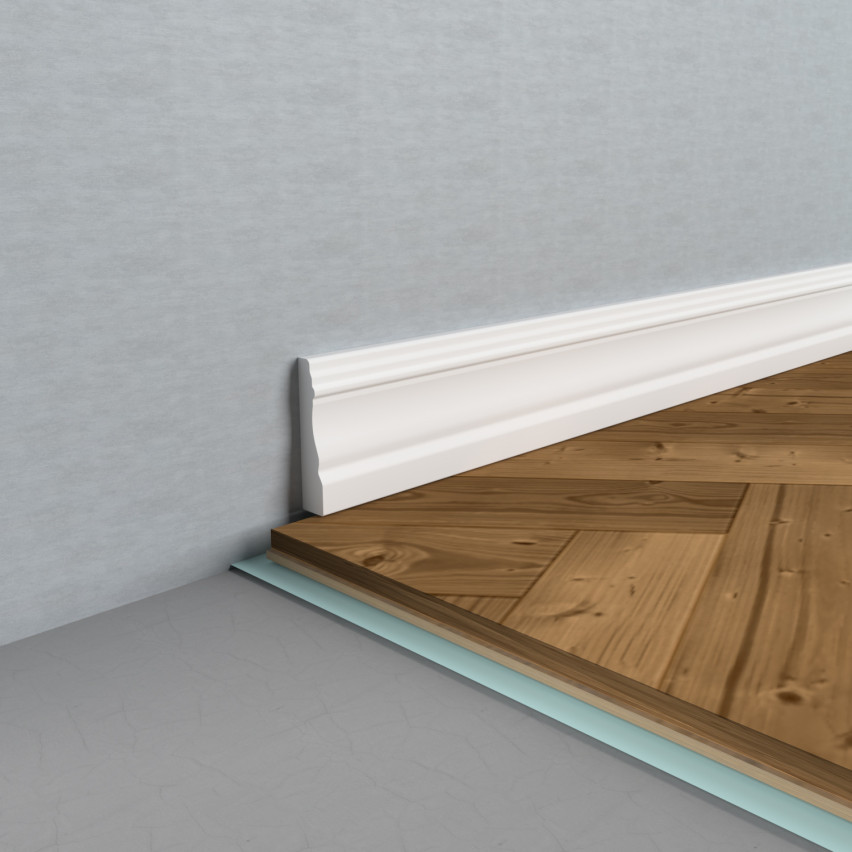

Illustrative Image (Source: Google Search)

Bullnose

– Profile: Fully rounded face for maximum edge safety and minimal chipping risk.

– Material: Solid PVC core and skin; 16 mm thickness; White (RAL No. 9003).

– Installation: Adhesive-only; minimal cleaning requirements.

– Typical applications: Childcare facilities, hospitality, residential, and any project prioritising safety and a simple, tactile profile.

– Considerations: Offers a restrained aesthetic; consider colour contrast and lighting to maintain visual definition.

Adhesive-Only Installation

– Method: Boards are bonded with widely accessible adhesives; no nails or screws.

– Workflow advantage: Eliminates preparation (sanding/painting) and reduces fixing steps, with Freefoam indicating up to 50% time savings.

– Surface suitability: Requires sound, clean, and appropriately prepared substrates; very uneven surfaces should be rectified to ensure full adhesive contact and long-term performance.

– B2B relevance: Ideal for occupied buildings, fast-turn refurbishments, and projects aiming to minimise disruption.

Colour and Finish Matching

– White: Freefoam references White (RAL No. 9003) for the skirting boards covered here; they note RAL numbers are nearest equivalents.

– Adjacent finishes: Related product ranges include Agate Grey (RAL 7038), Matte Foil Anthracite Grey (RAL 7016), Matte Foil Black (RAL 9011), and woodgrain options (e.g., Light Oak nearest RAL 8001). Confirm compatibility with specified skirting type and batch consistency on a per-project basis.

Selection Guidance

– When a classical look is needed, choose ogee; when clean, modern lines are required, choose chamfer/flat; for safer edges in busy environments, choose torus or bullnose.

– For refurbishments and occupied spaces, adhesive-only installation reduces time and mess.

– Always verify the exact colour RAL across skirting and adjacent trims and confirm any project-specific tolerances beyond the standard 16 mm thickness.

Illustrative Image (Source: Google Search)

Key Industrial Applications of white pvc skirting board

Key Industrial Applications of White PVC Skirting Board

Use the matrix below to identify where white PVC skirting is typically specified and why it supports faster turnover, lower maintenance, and longer service life in demanding environments.

| Industry | Typical applications | Fast install (fit & forget) | Low maintenance (no finish) | Moisture & impact resistance | Hygiene & cleanability |

|---|---|---|---|---|---|

| Healthcare (hospitals, clinics, care homes) | Corridors, patient rooms, nurses’ stations, dayrooms | 16 mm solid core, direct adhesive installation; no nails/screws; quick turnkey fit-outs; up to 50% faster fitting | No painting or sanding; wipe clean with a moist cloth | Withstands trolley/bump traffic; solid PVC core and skin; resists scuffs | Smooth, non-porous surface aids sanitation between handovers |

| Food & beverage (production, storage, retail kitchens) | Cold rooms, prep areas, aisles, checkout zones | Adhesive application accelerates busy-floor installs; minimal downtime | Resilient finish avoids repainting cycles; easy post-shift clean | 16 mm profile resists impact; moisture wipe-down suited to frequent sanitation | Non-wood surface simplifies hygiene protocols |

| Retail & hospitality (stores, restaurants, hotels, cafes) | Shop floors, back-of-house, hotel corridors and lobbies | Install without sanding/painting; rapid brand-standard rollouts | Maintains white finish with regular wipe-down | 16 mm thickness endures frequent footfall and cart contact | Clean, uniform appearance supports brand hygiene standards |

| Education (schools, colleges, universities) | Classrooms, corridors, labs, school kitchens | Efficient adhesive fit-outs minimize classroom disruption | Minimal upkeep reduces maintenance windows | Withstands corridor bumps; durable PVC construction | Easy to keep tidy between terms |

| Commercial offices (HQs, business parks) | Open-plan floors, breakout areas, stairwells | Fast adhesive installation supports agile refurbs | No repainting; simple custodial cleaning | Resists daily knocks from chairs/carts | Keeps public-facing areas presentable |

| Transport hubs (airports, rail stations, bus terminals) | Concourses, retail shells, service corridors | Install without nails/screws; low disruption to traffic flow | Easy to clean in multi-shift operations | 16 mm profile handles heavy pedestrian and trolley traffic | Supports clean passenger environment |

| Industrial & logistics (warehouses, factories, garages) | Aisles, pick/pack zones, workshops | Adhesive method reduces downtime | Wipeable finish avoids repaint cycles | Solid core/skin construction stands up to impact | Practical surface for multi-use zones |

| Sports & leisure (gyms, pools, clubhouses) | Gym floors, changing rooms, pool surrounds | Quick-fit upgrades during off-season closures | Wipe-clean surface simplifies recurring maintenance | Durable with everyday use; wipeable finish | Helps maintain hygienic, bright interiors |

| Public sector & community facilities (town halls, libraries, civic centres) | Public corridors, meeting rooms, office lobbies | Efficient installation without sanding or painting | Ongoing care limited to a quick wipe | Withstands public traffic and chair/scuff contact | Presents a uniform, clean finish |

| Veterinary & animal care (clinics, kennels, catteries) | Waiting rooms, treatment areas, corridors | Fast adhesive install with minimal disruption | Easy decontamination after procedures | Resists impacts common in handling areas | Wipe-down compatibility supports infection control |

Notes for specification

– Adhesive installation: Standard commercial adhesives can be used for direct bonding, eliminating the need for nails or screws and speeding up fitting by up to 50%.

– Low maintenance: Requires no sanding or painting; routine cleaning with a moist cloth maintains appearance.

– Durability: 16 mm thickness with solid PVC core and skin provides impact resistance for busy commercial applications.

– Colour availability: White RAL 9003 is typically stocked to complement institutional finishes and brand palettes.

3 Common User Pain Points for ‘white pvc skirting board’ & Their Solutions

3 Common User Pain Points for White PVC Skirting Board & Their Solutions

| Pain Point | Scenario / Problem | Solution |

|---|---|---|

| Time-consuming installation and finishing | Traditional materials require sanding/priming, nailing/screwing, and site finishing to achieve a tidy result. | Use white PVC skirting boards; adhere with widely accessible adhesives for a low-maintenance, fast fix. No nails/screws and no finishing steps can save up to 50% of fitting time. |

| Ongoing maintenance and appearance stability | Painted wood or MDF skirting chips, scuffs, and fades, needing regular repainting. | Choose white PVC skirting boards; they deliver the look of wood without the work. Post‑installation upkeep is minimal—wipe with a damp cloth; repainting is not necessary. |

| Durability in high‑traffic environments | Frequent bumps and knocks damage standard skirting, leading to dents and repairs. | Specify 16mm white PVC skirting boards with a solid PVC core and skin for strong, long‑lasting performance in commercial and residential spaces. |

1) Install Speed & Finishing

- Scenario: Projects using timber/MDF skirting face extended installation time due to sanding, priming, and finishing; visible fixings complicate a clean aesthetic.

- Solution: White PVC skirting boards install quickly using widely available adhesives; no nails/screws are required and the material needs no finishing/preparation. This method consistently delivers a tidy, expert finish while reducing fitting time by up to 50%.

2) Maintenance & Appearance Stability

- Scenario: Painted skirting chips and fades, especially in high‑traffic areas, prompting recurring touch‑ups or repainting.

- Solution: White PVC skirting boards provide the look of wood without ongoing refinishing. After installation, upkeep is minimal—wipe with a damp cloth; repainting is not necessary.

3) Durability & Longevity

- Scenario: Standard boards dent or scuff from routine contact in busy spaces, increasing maintenance and replacement costs.

- Solution: Freefoam’s 16mm white PVC skirting boards feature a solid PVC core and skin, delivering durable performance that withstands frequent impacts—ideal for home and workplace use.

Notes:

– Nearest RAL equivalent for White: RAL 9003 (Freefoam FOS125).

– The system is described for fast fixes; adhesive selection should follow project requirements and substrate conditions.

Strategic Material Selection Guide for white pvc skirting board

Strategic Material Selection Guide for White PVC Skirting Board

Executive summary

White PVC skirting boards offer a fast, low-maintenance, and durable finish compared with traditional materials. For professional B2B buyers specifying across USA and European projects, the primary advantages are rapid adhesive-only installation (up to 50% time savings), no finishing/painting, a consistent RAL 9003 white appearance, and a solid PVC core/skin construction with 16 mm thickness to withstand everyday knocks. This makes PVC skirting particularly suitable for commercial interiors, healthcare, education, residential retrofits, and any site where installation speed, hygiene, and lifecycle simplicity are priorities.

Illustrative Image (Source: Google Search)

Material analysis

- Core and skin: Solid PVC core and skin; structural stability without fiber exposure.

- Thickness: 16 mm for robust resistance to bumps in high-traffic interiors.

- Profile: Ogee-shaped, providing a classical aesthetic with good scuff concealment.

- Finish: High-quality white surface; RAL 9003 equivalent; no painting required.

- Color availability: White (RAL 9003) is available; RAL numbers provided are the nearest equivalents.

- Installation method: Adhesive-ready, enabling bond-and-fix methods without nails or screws (can save up to 50% of fitting time).

- Post-install upkeep: Minimal; routine cleaning with a damp cloth; no repainting needed.

Performance attributes

- Durability and impact resistance: 16 mm solid PVC construction resists scuffs and knocks typical of occupied spaces, reducing callbacks and maintenance.

- Humidity stability: Closed-cell PVC core minimizes swelling; avoids moisture-driven movement associated with wood/MDF.

- Aesthetic consistency: Uniform RAL 9003 finish and low-gloss surface; compatible with standard white door surrounds for systemized look.

- Chemical and stain resistance: Closed surface resists common cleaning agents; suited for daily wipe-down regimes.

- Thermal behaviour: PVC is dimensionally stable across typical interior climates; follow expansion joint guidance in larger runs.

- VOC and indoor air quality: No finishing/painting reduces on-site VOC sources; inherent cleanliness supports low-dust sites.

- Sustainability: PVC is recyclable in many locales; low-rework and no paint waste reduce lifecycle impact.

- Fit-and-forget: Eliminating finishing steps improves schedule reliability and reduces on-site coordination risks.

Decision criteria by project type

- Residential retrofits (fast track): Adhesive-only install saves time; low maintenance benefits occupancy turnover speed and tenant satisfaction.

- Commercial interiors (offices, retail): Durability, stain resistance, and paint-free finish reduce downtime, janitorial burden, and lifecycle costs.

- Healthcare and education: Hygienic, easy-to-clean surfaces support infection control regimes and frequent sanitization.

- Hospitality and high-traffic zones: Resistance to scuffs and knocks maintains aesthetic continuity; white RAL 9003 harmonizes with common finishes.

- New-build and OEM: RAL 9003, consistent stock, and adhesive-ready format improve procurement and site logistics.

Specification and procurement guidance

- Specify: White PVC skirting boards, 16 mm thickness, RAL 9003 finish, ogee profile; include adhesive-only installation method and no painting/finishing requirements.

- Standards and compliance: Reference applicable interior finish and VOC standards (e.g., EN, ASTM classifications). Verify fire performance where required by local code.

- Jointing: Use compatible PVC adhesives and fillers for seamless joints; observe adhesive open times. Allow for controlled expansion joints in long runs per manufacturer guidance.

- Substrate preparation: Ensure surfaces are clean, dry, and structurally sound to maximize adhesive bond; avoid dusty or friable substrates.

- Warranty and stock: Align to regional inventory and lead times; confirm RAL equivalent acceptance where white is tied to project palette.

- Tools and consumables: Adhesives, finishing knives, and wiping cloths; eliminate nail/screw inventories on fast-track packages.

Risk and compliance notes

- Fire performance: Confirm reaction-to-fire classification for project compliance; do not rely on general material claims without documentation.

- VOCs/indoor air: Validate low-emission profiles against regional standards and procurement policies; painting eliminations typically reduce on-site emissions.

- Adhesive compatibility: Use solvent-free or low-VOC adhesives rated for PVC; avoid aggressive plasticizers that may migrate and stain.

- Tolerances and finishes: Standardize jointing and corner treatments to avoid visible color/finish discrepancies; maintain RAL consistency across packages.

- Dimensional stability: Observe expansion joint spacing and allowance in HVAC environments with wide diurnal swings.

Quick checklist for specifiers

- Thickness: 16 mm, solid PVC core/skin.

- Color: White RAL 9003; accept nearest equivalent note.

- Installation: Adhesive-only; no finishing/painting.

- Maintenance: Damp cloth wipe-down; no repainting required.

- Complementary items: Door surround system in matching white for a cohesive finish.

Comparative material selection

The table below summarizes key material selection factors for skirting in commercial and residential interiors. Values reflect typical behaviors and project needs; confirm specific product data for compliance-critical parameters.

| Material | Thickness (typical) | Finish required | Installation speed | Maintenance | Moisture performance | Impact resistance | Dimensional stability | VOC profile | Fire rating compliance | Color consistency | Typical use cases |

|---|---|---|---|---|---|---|---|---|---|---|---|

| White PVC (solid core/skin) | 16 mm | None; paint-free | Fast: adhesive-only (up to ~50% faster) | Very low; wipe-down | Excellent (no swelling) | High; resists scuffs/knocks | High; minimal expansion | Low (no paint) | Specify product-specific rating | Very high; RAL 9003 | Commercial interiors; healthcare; education; hospitality; retrofits |

| MDF (primed) | 12–18 mm | Primed; painting expected on-site | Moderate; nails/screws + filling/sanding | Medium; paint can scuff | Sensitive to humidity | Medium; can chip/splinter | Medium; can move with RH changes | Medium–high (primers/paints) | Must verify | Medium (paint batch variation) | Residential painted interiors; budget projects |

| Painted timber (softwood) | 12–20 mm | Priming + painting | Moderate; nails/screws + sanding/painting | Medium–high | Sensitive; can swell/stain | Medium | Medium; can warp/check | Medium–high (finish materials) | Must verify | Medium (paint variation) | Traditional/rustic aesthetics; renovation |

| HDF/PU foam skirting | 10–16 mm | Painted to match decor | Fast | Medium | Medium; foam can degrade if exposed | Medium | Medium | Medium–high (if painted) | Must verify | Medium–high (paint dependent) | Budget decorative profiles; light-duty |

| Polystyrene (PS) foamed | 10–16 mm | Often painted; sometimes unpainted | Fast | Low–medium | Medium | Low–medium (brittle) | Medium | Medium–high if painted | Must verify | Medium (paint dependency) | Light-duty, low-impact areas |

| Gypsum plaster coving/skirting | 10–20 mm | Priming + painting | Slow; install + finish/feather | Medium | Medium; can craze with moisture | Low–medium | Medium | Medium | Must verify | Medium (paint variation) | High-end detailing; low-impact environments |

Recommendation

Select white PVC skirting boards (16 mm, RAL 9003, ogee) for schedules where installation speed, consistent appearance, and low lifecycle upkeep are decisive. Retain traditional materials (timber/MDF/gypsum) where specified architectural intent or localized code requirements demand them; otherwise, PVC’s adhesive-only, paint-free, and durable profile will reduce time-to-close and total cost of ownership across USA and European projects.

In-depth Look: Manufacturing Processes and Quality Assurance for white pvc skirting board

In‑depth Look: Manufacturing Processes and Quality Assurance for White PVC Skirting Boards

1) Manufacturing Overview

- 16 mm white PVC skirting boards are typically produced via co‑extrusion. This combines a solid PVC core with a white PVC skin to deliver consistency in surface finish, dimensional stability, and color uniformity.

- The white skin is formulated with high-purity PVC, titanium dioxide (TiO2), and colorants to achieve White RAL 9003.

- The process is “fit-and-forget”: no sanding or painting is required post-installation, which reduces labor on site and minimizes maintenance.

2) Process Flow

Prep (Raw Materials and Formulation)

- Raw materials: PVC resin, stabilizers, impact modifiers, lubricants, TiO2 (white), pigments; consistent lot-to-lot control.

- Drying and blending: hygroscopic compounds dried to a defined moisture spec; dry-mixed under inert conditions to minimize degradation and color variation.

- Color matching: white is target-matched to RAL 9003 under D65 illuminant; batch-to-batch color monitoring with defined ΔE tolerances.

- Material handling: FIFO, moisture barriers, sealed storage to protect TiO2 and prevent fines contamination.

Forming (Extrusion and Cooling)

- Screw design and barrel zone controls: throughput and shear tailored for PVC-U to achieve melt homogenization without degrading stabilizer package.

- Die and calibrator: precision tooling yields stable dimensions and surface finish; co-extruded skin/core flowlines calibrated for adhesion and integrity.

- Line speed and melt temperature: controlled to balance surface gloss, dimensional accuracy, and extrusion stability.

- Vacuum calibration and water cooling: multi-zone cooling to lock-in profile geometry and minimize internal stress or warpage.

- In-line controls: continuous dimensional gauging, defect detection, and automatic cut-to-length to hold tolerance.

Assembly/Finishing

- Cutting: precision cutting to standard lengths, mitres for internal/external corners, and pre-drilled profiles if specified.

- Optional surface finishing: lightweight sanding only if minor edges require it; no paint required.

- Adhesive suitability: profiles are designed to accept commonly available construction adhesives for rapid installation (no need for nails/screws); optional mechanical fixings available for specific substrates and load cases.

- Packaging: corner protection, stackable bundles, labeling with code, dimensions, and color.

Packaging and Logistics

- Handling: soft-touch spacers to prevent scuffing of white skin.

- Stack height and palletization: designed to avoid deformation; orientation preserved for transport.

- Identification: batch traceability on pack labels and technical documents.

3) Quality Assurance and Quality Standards

3.1 Incoming Materials

- PVC, TiO2, additives verified for purity and specification compliance.

- Certification package available to purchasers on request (e.g., master batch certifications, stabilizers certificates).

- Batch color samples retained and logged for traceability.

3.2 In‑process Controls

- Extrusion parameters: melt temperature, screw speed, and line speed monitored in real time; alarms set for defined excursions.

- Calibration: dimensional checks across height, thickness, leg width, and face angle; sampling rates per lot defined by the QMS.

- Surface checks: visual inspection for haze, pinholes, flow lines, and die lines; gloss measured where applicable.

- UV/color stability: TiO2 levels and stabilizer packages verified to target Whiteness Index; periodic exposure tests to monitor color consistency.

3.3 Dimensional and Performance Verification

- Thickness verification: 16 mm target maintained across the profile.

- Impact resistance: check for resilience against frequent bumps in commercial and domestic environments.

- Installation fit: checks for flatness/straightness and corner/mitre accuracy to ensure tidy, professional finishes on site.

- Adhesive compatibility: periodic pull/creep tests with common construction adhesives; acceptance criteria defined in supplier specifications.

3.4 Documentation and Traceability

- Batch logs: mix codes, extrusion parameters, calibration records, QC test results.

- Shipment documentation: technical datasheets, product codes (e.g., FOS series), color mapping (RAL 9003), and installation notes provided with shipment.

4) Quality System Standards

| Area | Standard | Relevance |

|---|---|---|

| Quality Management | ISO 9001 | Process control, continuous improvement, documented procedures, and traceability. |

| Environmental Management | ISO 14001 | Environmental policy, resource and waste management for PVC processing. |

| Occupational Health & Safety | ISO 45001 | Site safety and operator protection across extrusion, handling, and packaging. |

| Fire and Flammability | ISO 4589 (Oxygen Index) / ISO 1210 (UL 94) | Classifying burning behavior of plastics; used by EU Member States and North America as part of fire classification frameworks. |

| Building Codes | EU: Construction Products Regulation (CPR) | Performance documentation required for placing products on the EU market; EN 13501-1 classification for fire reaction. |

| Local Codes | USA: IBC/IFC; ASTM test methods (e.g., ASTM D2863, E84) | Classification and verification of fire performance in commercial and residential construction. |

| Emissions (Optional) | REACH; Low VOC programs (e.g., GREENGUARD) | Supports Indoor Air Quality claims; relevant for sensitive environments. |

5) Performance and Maintenance Summary

- Material: Solid PVC core and white PVC skin; 16 mm thickness.

- Finish: White RAL 9003; ready-to-install; no sanding/painting required.

- Installation: Compatible with commonly available adhesives; optional mechanical fixings where needed.

- Maintenance: Low; routine cleaning with a damp cloth; repainting not necessary.

- Durability: Designed to tolerate frequent impacts in workplaces and homes.

6) Installation Notes for Specifiers

- Substrate: Verify adhesion compatibility and suitability of chosen adhesive with substrate and environmental conditions.

- Thermal movement: Consider substrate movement and provide allowances per project requirements.

- Fastening option: Where mechanical fixing is preferred, pre-drilling and appropriate anchors are available.

7) Commercial Considerations

- Lead time: Standard production with batch QA; batch traceability enables consistent deliveries and easy recalls if required.

- Warranty coverage: Refer to product-specific warranty statements (where available) and installation conditions.

- Compliance: Ensure local/state/province regulations are met, including fire performance classifications and any building permit requirements.

This process framework aligns with recognized international quality system standards and addresses fire performance documentation standards applicable to North America and the EU. Where compliance demands exceed general PVC-U product data, provide project-specific test reports or certifications prior to tendering and procurement.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘white pvc skirting board’

Practical Sourcing Guide: A Step-by-Step Checklist for White PVC Skirting Board

Use the following checklist to specify, evaluate, and place orders with confidence. It is designed for USA and Europe, drawing on widely adopted Freefoam specifications (16 mm solid core and skin; White RAL 9003 equivalent) and adhesive-fixed installation practices.

1) Define the Technical Specification

- Material and structure: uPVC with solid core and skin; 16 mm thickness recommended for impact resistance and stable handling.

- Finish: High-gloss white (equivalent to RAL 9003).

- Profile: Ogee (recommended for new builds/refurb) or square leg if matching adjacent profiles.

- Dimensions: Height and wall coverage from the chosen profile; standard stock length (e.g., 2.4 m or 3.0 m; confirm per supplier).

- Color consistency: Ensure single batch and confirm RAL equivalence statement on technical documentation.

- Reference example: Freefoam White PVC Skirting Board (Code: FOS; 16 mm thickness; White RAL No. 9003).

Table: Specification inputs

| Parameter | What to capture | Notes |

|—|—|—|

| Thickness | 16 mm (recommended) | Common in Freefoam range for impact resistance. |

| Profile | Ogee or square leg | Choose based on design and adjacent fascias/cladding. |

| Finish | White RAL 9003 | Verify “nearest equivalent” note if stated. |

| Length | Standard stock lengths | Confirm per supplier; plan cut strategy. |

| Wall coverage | Height + projection | Allow for wall irregularities. |

2) Select the Installation Method

- Adhesive-bonded: Reduces prep and finishing; can cut installation time significantly compared to mechanical fixing, per Freefoam guidance. Confirm surface condition and curing schedule.

- Mechanical fixing (optional): Screws/nails suitable where adhesives are not preferred; verify wall type (drywall, plaster, masonry) and appropriate fasteners.

Table: Installation methods

| Method | Pros | Cons | Typical use cases |

|—|—|—|—|

| Adhesive (PVC-compatible) | Fast fit; minimal prep; paint-free finish | Surface must be clean/flat; curing time | Refurbishments; low-maintenance projects |

| Screws/anchors | High fixing certainty | More prep; visible fixings if not covered | Heavy-duty environments; contractor preference |

3) Set Dimensional and Packaging Requirements

- Stock length vs. cut-to-length; consider waste allowances and joins.

- Protection: Protective film, edge guards, and palletization for transport and site storage.

- Pack quantity: Confirm units/pack (e.g., Freefoam: 5 Units/Pack; verify per item).

- Delivery formats: Single packs or palletized shipments, shrink-wrapped.

Table: Packaging & delivery summary

| Factor | USA | Europe | Verification |

|—|—|—|—|

| Pack quantity | Confirm per supplier SKU | Confirm per supplier SKU | Check catalog/packing list |

| Palleting | 5 Units/Pack; palletized deliveries | 5 Units/Pack; palletized deliveries | Supplier shipping docs |

| Protection | Film + edge guards | Film + edge guards | Visual inspection on receipt |

| Length | Stock (confirm); cut-to-length | Stock (confirm); cut-to-length | Purchase order & delivery note |

4) Pre-Order QA and Document Checks

- Product information: SKU, code, and description (e.g., FOS).

- Batch traceability: Delivery note must show batch/lot for color matching.

- Finish and dimensions: Visual check for gloss, uniformity, and 16 mm thickness.

- Datasheets: Confirm RAL 9003 equivalent and any finishing notes.

- Accessories: Confirm compatible adhesives, primers, fillers, trims, and expansion joints if needed.

5) Adhesive System Selection (if adhesive-bonded)

- Adhesive: Use PVC-compatible construction adhesives suitable for interior walls.

- Surface prep: Clean, dry, dust-free; lightweight sanding of glossy substrates if required by adhesive manufacturer.

- Application: Follow bead pattern, contact time, and curing guidance on adhesive packaging.

- Ventilation: Ensure adequate airflow during curing; observe local VOC/safety requirements.

Table: Adhesive selection checklist

| Criterion | What to check | Why it matters |

|—|—|—|

| Substrate compatibility | Drywall/plaster/masonry | Affects bond strength |

| Adhesive type | PVC-compatible | Prevents edge lift, discoloration |

| Curing & contact time | As per manufacturer | Ensures reliable adhesion |

| VOC/safety | Local compliance | Safe installation and site use |

Illustrative Image (Source: Google Search)

6) Quantity Takeoff and Ordering

- Measurement: Perimeter minus openings; add percentage for waste (usually 10–15%, depending on layout).

- Delivery windows: Confirm lead times and site delivery access for pallets.

- MOQs: Verify pack-level minimums; order whole packs to avoid shortfalls.

- Purchase order: Include SKU, code, profile, thickness, finish, lengths, pack qty, delivery address, delivery window, and RAL equivalence statement.

Table: Order planning inputs

| Input | Example or guidance |

|—|—|

| Perimeter measurement | Sum of wall runs minus doorways |

| Waste factor | 10–15% typical; site-specific |

| Pack qty | Order whole packs (e.g., 5 Units/Pack) |

| Delivery | Date, access, contact, unloading |

7) Delivery and Site Handling

- Inspection at dock: Check packs, SKUs, batch/lot, and visible damage.

- Storage: Dry, flat, protected from sunlight/heat; remove film only after installation to avoid marks.

- Handling: Use edge guards; avoid dragging across floors; stack safely.

8) On-Site Installation Notes (Adhesive Fixed)

- Cut and dry-fit: Measure, cut 45° internal corners; square cut at returns and ends.

- Adhesive application: Apply beads per adhesive guidance; press and hold; maintain clean-up of squeeze-out.

- Alignment: Check uniform height; use temporary spacers if needed.

- Finish and cleaning: Wipe with a damp cloth; no painting required per Freefoam guidance (time savings and low maintenance).

9) Quality Assurance and Defect Handling

- Visual inspection: Color consistency within batch; correct profile; no damage or warp.

- Fit and finish: Straight lines, tight corners, clean cut edges.

- Action on issues: Document defects, isolate batch, and contact supplier with batch references for resolution.

10) Final Walkthrough and Handover

- Verify all sections installed; check adhesion points for continuity.

- Confirm low-maintenance care: Routine wipe cleaning; no repainting.

- Project documentation: Deliverable checklist, batch logs, warranty/claims process.

Table: Project acceptance checklist

| Check | Pass/Fail | Notes |

|—|—|—|

| Color batch match | | |

| Profile dimensions (16 mm) | | |

| Adhesive bond quality | | |

| Corner cuts and joins | | |

| Visual finish | | |

This checklist aligns with Freefoam’s guidance on white PVC skirting boards (16 mm, solid core and skin; White RAL 9003 equivalent; adhesive-fixed installation can save significant fitting time), while enabling USA/Europe procurement teams to specify, order, and execute with professional rigor.

Comprehensive Cost and Pricing Analysis for white pvc skirting board Sourcing

Comprehensive Cost and Pricing Analysis for White PVC Skirting Board Sourcing

How to read this analysis

- Price in USD is a nominal proxy for international buyers. Adjust for local taxes and currency.

- Cost ranges reflect typical supplier quotes and installation norms across USA and Europe. Your actual prices may vary due to project location, supplier tier, and installation method.

Methodology

- Use linear meters (lm) as the primary unit.

- Base installation on 16 mm, foamed/PVC-cored skirting (profile similar to Freefoam FOS series).

- Labor times include on-site handling, measurement, cutting, bonding, and finishing.

- Logistics cost uses freight weight ~1.0–1.4 kg/lm for solid profiles, ~0.5–0.8 kg/lm for hollow profiles.

Unit economics: materials, labor, logistics (per linear meter)

| Line item | Unit | Typical cost range (USD) | Typical cost range (EUR) | Notes |

|---|---|---|---|---|

| Material: white PVC skirting 16 mm (RAL 9003), Foamed core (hollow) | $/lm / €/lm | 5.0–8.0 | 4.5–7.0 | Wide, high-impact profiles trend higher |

| Material: white PVC skirting 16 mm (RAL 9003), Solid core | $/lm / €/lm | 7.5–12.0 | 6.5–10.0 | Solid PVC for high-traffic and renovation durability |

| Adhesive bonding (Hybrid/MS polymer) | $/lm / €/lm | 0.15–0.40 | 0.12–0.35 | One cartridge ~200–300 lm coverage (typical bead). Reduces installation time and substrate damage |

| Fasteners (mechanical option) | $/lm / €/lm | 0.10–0.25 | 0.09–0.22 | Plugs/screws, plus pilot holes and filling |

| Sealant (if finished joints required) | $/lm / €/lm | 0.05–0.15 | 0.04–0.12 | Optional; not always needed with adhesion-only methods |

| Labor (adhesive bonding) | $/lm / €/lm | 2.0–5.0 | 1.5–4.0 | Clean wall line; bead; hold/clip-in; wipe-down; up to ~50% faster vs nailing/drilling |

| Labor (mechanical fixing) | $/lm / €/lm | 3.5–8.0 | 3.0–6.5 | Drill, plug, screw; optional fill/finish |

| Logistics: inland truck | $/kg / €/kg | 0.05–0.15 | 0.04–0.12 | Typical LTL |

| Logistics: international sea | $/kg / €/kg | 0.02–0.06 | 0.02–0.05 | Minimum 1–2 CBM per SKU typical |

| Logistics: air (urgent) | $/kg / €/kg | 2.0–6.0 | 1.8–5.0 | Use only for time-critical replacements |

| Landed duty & fees (illustrative) | % of CIF | 3.0–8.0 | 3.0–8.0 | Varies by HS code, origin, and trade terms |

| VAT/Sales tax (USA) | % of landed | 0–9.0 | — | State/local varies (e.g., EU VAT typically 19–27%) |

| Packaging/waste | $/lm / €/lm | 0.10–0.30 | 0.08–0.25 | Includes pallets, wrap, and cut-off removal |

| QA/Returns/waste | $/lm / €/lm | 0.05–0.25 | 0.04–0.20 | Allow for minor damage/mix-ups |

Notes:

– Material savings from adhesives vs nails/screws come from speed, reduced tooling, and avoiding wall damage; Freefoam cites “fit-and-forget” with adhesives and up to 50% saving in fitting time.

– Hollow profiles are lighter and cheaper to ship; solid profiles trade off weight/cost for higher impact resistance.

Illustrative Image (Source: Google Search)

Example: landed cost comparison (illustrative)

Assumptions:

– 1,000 lm order

– Profile weight: hollow ~0.65 kg/lm; solid ~1.2 kg/lm

– Logistics (sea LCL + inland): hollow ~$0.08/kg; solid ~$0.10/kg

– Duty and fees ~5% of CIF

– Labor: adhesive bonding

– Installation speed: adhesive ~50% faster than mechanical

| Profile | Product cost | Logistics | Duty/fees | Labor | Total installed (range) |

|---|---|---|---|---|---|

| Hollow 16 mm white | $5,500 | $52 (1000×0.65×0.08) | ~$280 | $2,500–$4,000 | $8,300–$10,300 |

| Solid 16 mm white | $8,000 | $120 (1000×1.2×0.10) | ~$400 | $2,500–$4,000 | $11,000–$12,500 |

Simple example:

– Hollow: $9/m (material) + $0.08/kg logistics (≈0.65 kg/lm → $0.05) + duty/fees (≈$0.03–$0.06/lm) + adhesive (≤$0.40/lm) + labor (adhesive, $2.5–$4.0/lm). Total ≈ $11.7–$14.2/lm.

– Solid: similar adders lead to ≈ $14.5–$17.5/lm.

Labor productivity: adhesive vs mechanical

| Activity | Adhesive bonding | Mechanical fixing |

|---|---|---|

| Surface prep | Light dust-off and test adhesion | Light prep + pilot drill |

| On-site time | Faster cure and no plugs | Plug/screw, then fill/sand |

| Finish passes | Minimal wipe-down | Optional fill/sand/finish |

| Typical time (per 30 lm day) | Full coverage within a working day | 1.5–2.0 days |

| Upfit/renovation risk | Low wall damage | Wall plugs and patching |

The adhesive route is a practical fit-for-purpose approach in many projects and can save up to 50% of fitting time when properly specified.

Pricing levers to reduce landed cost

- Prefer larger runs to unlock supplier tiers; ask for MOQ discounts and early payment terms.

- Use hollow profiles where impact resistance is sufficient; weight savings translate directly to logistics.

- Bundle SKUs (e.g., profiles + corner joints + adhesives) for a single freight linehaul and negotiate all-in pricing.

- Ship at schedule-optimized volume (avoid air freight unless unavoidable).

- Coordinate packaging: uniform palletisation reduces handling fees.

- Specify RAL 9003 white in advance to avoid color surcharges and rework.

- Match adhesive to substrate chemistry; perform onsite adhesion checks to avoid failures and call-backs.

- For USA: leverage domestic carriers and regional DCs; for EU: exploit intra-EU customs optimization (e.g., FTZ, bonded warehousing).

Risk and mitigation (cost implications)

- Color batching: order with a single production lot to avoid “white” shade drift. Small deviations can trigger rework and replacements.

- Substrate mismatch: test adhesive on painted/rendered walls and Gyprock; avoid solvent adhesives on sensitive paints.

- Profile deflection: tall/flat profiles with hollow cores can dent; use solid or limit exposure in high-traffic corridors.

- Compliance: verify REACH/ROHS for EU and US compliance; ensure adhesives/sealants meet VOC/indoor air limits.

Where the cost lives (USA vs Europe)

- USA: labor rate volatility by state/city; longer trucking lanes; lower VAT but localized sales tax.

- Europe: often tighter color/finish standards; VAT adds to consumer prices; shorter intra-EU logistics enable multi-drop routes.

Procurement checklist (quick reference)

- Material: White PVC 16 mm, RAL 9003 (hollow vs solid), profile width, pack length, impact class if specified.

- Logistics: freight mode, weight per lm, INCOTERMS (e.g., EXW vs DAP), customs broker support.

- Labor: adhesive brand and substrate list; method; install speed targets; waste allowance.

- Compliance: REACH/ROHS, VOC/CA Section 01350 where applicable, fire class (EN 13501) if required.

- Terms: warranty, MOQ, payment, lead time, packaging, certification evidence.

Bottom line

- Material choice (hollow vs solid) is the largest cost driver, followed by logistics and labor.

- Adhesive-based installation usually lowers total installed cost by cutting labor time and eliminating plugs/fillers, and it aligns with “low-maintenance” fit-and-forget performance.

- Weight optimization and freight planning (kg/lm, mode, batching) compound savings on larger projects.

Simple example:

– If adhesive installation cuts 2 hours per 100 lm off a job at $40/h, you save $80/100 lm; at $0.25/lm adhesive cost, net savings ~$80/100 lm. Over 5,000 lm, that’s ~$4,000—often enough to switch from air to sea freight.

Illustrative Image (Source: Google Search)

Alternatives Analysis: Comparing white pvc skirting board With Other Solutions

Alternatives Analysis: Comparing white PVC skirting board with other solutions

For interior fit-out projects in the USA and Europe, white PVC skirting boards are increasingly chosen over traditional MDF and solid wood where moisture, speed of installation, and lifecycle costs are critical.

Comparative overview

| Criteria | White PVC skirting board | MDF skirting | Solid wood skirting |

|---|---|---|---|

| Composition & appearance | Extruded rigid PVC, solid PVC core and skin; white (RAL 9003) option typical | Medium-density fiberboard; primed or paint-grade; often veneer/paint | Natural timber (e.g., pine, oak); natural grain, paintable |

| Typical thickness | ~16 mm (e.g., Freefoam white PVC) | 14–18 mm (varies by supplier) | 12–20 mm (varies by species/cut) |

| Moisture & water exposure | Closed-cell PVC resists water; suitable for damp areas | Swells/delaminates if edges/faces exposed to water | Movement (cupping/expansion) with humidity changes; higher risk when wet |

| Finish requirement | None; clean-install finish; no sanding/painting | Needs sanding and painting (often multiple coats) for full protection | Sanding and painting or staining/varnish; ongoing touch-ups |

| Installation | Adhesive-only (no nails/screws) can achieve up to ~50% time saving on fit-out (Freefoam claim) | Glue + nails/screws; caulk/seal edges for paint-grade finish | Glue + nails/screws; sand and finish; caulk as needed |

| Maintenance | Low: wipe-clean; repainting not required | Moderate: paint touch-ups; moisture-sensitive edges may need resealing | High: periodic painting/staining; scratch/wood damage repairs |

| Impact resistance | Good dent/bump tolerance due to thickness/core | Moderate; MDF can chip/soften under impact | Varies; hard species resist impact better, but finish can chip |

| VOCs/fumes | Low VOC; factory finish | Primers/paints add VOC during finishing | Primers/paints/varnishes add VOC; natural wood emissions are minimal |

| Reformability (scirting, arches) | Flexible for gentle curves; not structural | Good for routed profiles; limited flex for curves | Excellent for bespoke profiles; time-intensive on-site |

| Code/regulatory notes | Standard interior finishing; product compliance varies by country (e.g., CE where applicable in EU) | Standard interior finishing; formaldehyde emissions must meet local limits | Standard interior finishing; ensure sourced wood meets sustainability/ certification requirements |

Where each option fits

- White PVC

- Use cases: moisture-prone zones (bathrooms/kitchens), commercial interiors needing quick turnover, low-upkeep environments, renovations with tight timelines.

- Compliance: ensure VOC declarations, EU declarations/UK DoP and CE marking (where applicable) for procurement in Europe; confirm certifications for USA markets.

-

Notes: relies on adhesives; check substrate quality, temperature, and moisture at install; 16 mm thickness improves durability.

-

MDF skirting

- Use cases: cost-sensitive projects where a painted finish and moderate moisture exposure are acceptable.

- Compliance: confirm formaldehyde emission class and VOC content per regional standards; ensure primer and paint meet local limits.

-

Notes: protect edges (especially in damp areas); installation requires mechanical fastening and finishing.

Illustrative Image (Source: Google Search)

-

Solid wood skirting

- Use cases: premium interiors, staining to match natural wood finishes, high custom detailing and profiles.

- Compliance: verify wood certification and finish product VOC emissions.

- Notes: higher material and finishing labor; best in climate-controlled interiors or pre-finished environments.

Key takeaways

- Speed-to-install: White PVC’s adhesive-only approach and factory finish can save substantial labor versus MDF/wood, especially in rapid fit-out programs.

- Moisture performance: PVC outperforms MDF and wood in wet-prone areas due to water resistance and stability.

- Maintenance load: PVC typically requires only periodic cleaning; MDF and wood need ongoing finish upkeep to preserve appearance and edges.

- Lifecycle cost: PVC often delivers lower total cost when labor, finishing, and maintenance are considered across the project life.

- Compliance: Buyers should confirm declarations (EU CE/UK DoP), VOC/chemical content, and fire-class claims as required by local regulations before specification.

In many commercial and residential interiors, white PVC offers the best balance of installation efficiency, moisture resilience, and lifecycle cost, with MDF and wood remaining suitable where aesthetic priorities (e.g., natural wood appearance) or bespoke detailing dictate their selection.

Essential Technical Properties and Trade Terminology for white pvc skirting board

Essential Technical Properties and Trade Terminology for White PVC Skirting Board

Product overview (example: Freefoam FOS125)

- Product family: White PVC skirting board with ogee profile

- Thickness: 16 mm (durable, solid PVC core and skin)

- Typical finish: High-gloss white; color matched to RAL No. 9003 (referenced by manufacturer)

- Installation: Adhesive bonding—no nails or screws required

- Time savings: Up to 50% vs. traditional mechanical fixing/finishing

- Maintenance: Wipe clean; repainting not required

- Unit/Pack: Code FOS125; 5 units/pack

- Notes: “Nearest equivalent” RAL references are provided by the manufacturer; exact color match may vary by batch and viewing conditions

Key technical properties

| Property | Typical range/specification (for 16 mm white PVC skirting board) | Notes |

|---|---|---|

| Profile/section | Ogee; other profiles exist (see manufacturer range) | Check available profiles for alignment with doors/architraves |

| Thickness | 16 mm | 16 mm is the referenced thickness (Freefoam) |

| Finish | High-gloss white | RAL 9003 reference provided by manufacturer |

| Material | Solid PVC core and skin | Low absorption; no sanding or painting required |

| Density | 0.40–0.60 g/cm³ (typical for rigid PVC profiles) | Confirm with manufacturer if required |

| Vicat softening temperature (VST) | ~70–78°C (typical for rigid PVC profiles) | Provides upper use temp guidance; avoid heat sources |

| Linear thermal expansion | ~5–7 × 10⁻⁵/°C | Include allowance gaps; fix at centers per manufacturer guidance |

| Water absorption | Low; <0.1% (typical for rigid PVC) | Suitable for humid interiors; wipe away standing water |

| Flammability classification | Typically Class D (UL 94HB) for rigid PVC | Confirm local building code (US/EU) acceptance |

| VOC/emissions | PVC can emit VOCs initially; verify with lowVOC/REACH-tested products | For interiors, request EPD/EUROFINS IAQ data if needed |

| UV resistance | Good surface stability; color retention varies by finish | Check gloss retention and yellowing thresholds for white |

| Abrasion/scratch | Durable for normal wear | Avoid abrasive cleaners; test finish after adhesive contact |

Installation and handling notes

– Use manufacturer-recommended adhesives (e.g., MS polymer/solvent-free/contact adhesives per Freefoam guidance).

– Prepare substrate: dry, clean, sound, and at ambient temperature.

– Allow for movement: include expansion/allowance gaps at ends and joints (follow installer guide).

– Tools: fine-tooth saw, mitre box, and PVC-compatible adhesive/cleaners.

– Risk: some adhesives can cause stress whitening if applied incorrectly or cured under stress—follow product instructions.

Trade terminology (B2B essentials)

| Term | Definition | Typical values for white PVC skirting boards | Documentation needed |

|---|---|---|---|

| MOQ (Minimum Order Quantity) | Smallest purchasable quantity per SKU | 1 pack (example: FOS125 = 5 units/pack); may be 1 pallet for bulk | Order policy; SKU availability |

| Lead Time | Time from PO to shipment | In stock or 1–2 weeks; extended if bespoke | Stock confirmation; forecast lead time |

| Cut length | Custom cutting to size | Typical lengths 2.4 m; confirm availability | Length matrix; saw capacity |

| OEM/ODM | Custom branding, packaging, or profiles | White base; OEM is feasible; ODM (profile tooling) requires NRE and MOQ | NDA; tooling lead time; NRE |

| Packaging | Outerwrap/palletization for shipment | Palletized; protective wrap; banding | Packaging spec; max units/pallet |

| Logistics | Shipping, Incoterms, HS code | DAP or CIF (common); HS 3925 20 (typical for PVC boards) | Commercial invoice; Incoterms; HS code |

| Pricing | Commercial structure | Net ex-factory or CIF; discounts on volume | Price list; discount tiers |

| Storage | Stocking requirements | Cool, dry; avoid sunlight and high heat | Storage and handling SOP |

| Warranty/claims | Quality guarantee policy | Manufacturer-specific; request written warranty | Warranty terms; claim window |

| Quality | Standards and tolerances | ISO 9001 factory preferred; batch traceability | QA plan; batch records |

| Certification | Compliance documents | REACH; RoHS;VOC/IAQ; FSC for packaging | Certificates on request |

| RAL/finish | Color reference and gloss | White RAL 9003; gloss white | RAL swatch; finish spec |

| Adhesives | Fixing recommendations | PVC-compatible adhesives; solvent-free | TDS; SDS; application guide |

| Dimensional tolerances | Acceptable deviation | Confirm with manufacturer (typically ± x mm) | Tolerance sheet |

| Color matching | Batch color control | “Nearest equivalent” RAL; delta E tolerance | Color master; QA method |

| Fire rating | Material flammability | Confirm local code acceptance; typical UL 94HB | Certificates; code compliance letters |

| After-sales | Technical support | Installation guides; troubleshooting | Tech data sheets; helpline |

Compliance (US/EU)

- Confirm acceptance for interior use with applicable codes and standards (e.g., ASTM E84 for flame spread/smoke developed in the US; EN 13501-1 classing in the EU). If unavailable for white PVC skirting boards, request an “equivalent product classification” letter from the manufacturer.

- Request REACH, RoHS, VOC/IAQ (e.g., CDPH/EUROFINS) documentation for healthcare/education projects.

- Ensure adhesives/cleaners are low-VOC and compatible with PVC; obtain SDS/TDS for site safety.

Ordering checklist

- SKU and profile (e.g., FOS125, 16 mm ogee).

- Finish and RAL reference (White RAL 9003).

- Required lengths and quantities (units/packs/pallets).

- Incoterms, shipping address, requested ship date.

- Installation adhesive/cleaner type and compatibility.

- Required certificates (REACH/RoHS/VOC/IAQ/fire rating).

- Warranty confirmation and claim procedure.

Navigating Market Dynamics and Sourcing Trends in the white pvc skirting board Sector

Navigating Market Dynamics and Sourcing Trends in the White PVC Skirting Board Sector

Market outlook

- White PVC skirting boards continue to win share across refurbishment and new-build programs due to lower lifecycle cost, simplified installation, and consistent finish. They are often preferred in multi-unit housing, commercial interiors, hospitality, healthcare, and education—segments where turnaround speed and facility downtime are critical.

- Installer productivity improvements are a primary driver. Adhesive-fix systems eliminate nails/screws and finishing steps (sanding/painting), shortening fitting times and enabling consistent appearance; Freefoam highlights adhesive-based methods that can reduce fitting times by up to 50%.

- Durability and low maintenance underpin total cost advantage. 16 mm white PVC skirting boards with a solid PVC core and skin resist impacts and handle routine wear, and routine care requires only a quick wipe; repainting is not necessary.

- Color and spec standardization matter for large projects. RAL 9003 is the nearest equivalent white in European procurement; specification packages and site QA should align to RAL references, dimensional tolerances, and color batch codes.

Procurement and sourcing trends by region

| Topic | United States | Europe |

|---|---|---|

| Performance standards | Specify ASTM test regimes (e.g., impact resistance, VOC emissions) and building code compliance by state/city. Confirm fire behavior for multi-unit and commercial interiors. | Align to applicable EN standards and country-specific building regulations. For public interiors, ensure fire behavior requirements are met. |

| Moisture and humidity | Coordinate with HVAC commissioning. Specify core integrity and dimensional stability in humid zones (e.g., hospitality bathrooms, basements). | Same considerations; include moisture movement allowances during design and installation. |

| Finish expectations | Semi-matte or satin whites in commercial interiors; specify gloss level and color consistency across batches. | RAL 9003 is common for white. Verify “nearest RAL equivalent” notes in supplier specs and confirm batch-to-batch color control. |

| Installation | Mechanical fix remains common for certain applications; adhesive-fix is acceptable for many interior projects where substrates and curing conditions allow. | Adhesive-fix widely used on clean, prepared substrates; no nails/screws improves speed and finish quality. |

| Packaging and logistics | Use millwork-grade packaging to prevent scuffing; ensure full-length protection for transit. Specify handling SOPs to avoid corner damage. | Similar requirements; add heat-seasonal protection (shrink-wrap, racks) to mitigate warping in transit. |

| Minimum order quantities | Suppliers typically offer size/color flexibility but require volume commitments for custom or multi-size ranges. | Volume commitments and advance scheduling for RAL finishes; confirm batch continuity for large schemes. |

| Lead times | 4–8+ weeks for project orders. Consider buffer for US holidays and coastal routes; validate production slots and finish capacity. | 4–8+ weeks typical for Europe. Coordinate summer plant maintenance windows and logistics for long-haul routes. |

Quality and specification indicators

- Thickness: 16 mm profiles for enhanced impact resistance and professional appearance (e.g., Freefoam).

- Core construction: Solid PVC core with coextruded skin for dimensional stability and scuff resistance.

- Color: RAL 9003 white is the standard European equivalent; specify “nearest RAL 9003” if exact RAL matching is not available and request batch samples for approval.

- Accessory compatibility: Confirm availability of end caps, corners, and door surround systems to maintain consistent finish.

- Installation method: Adhesive-fix systems require clean substrates, approved adhesives, and correct curing; mechanical fix may be preferred where codes or conditions dictate.

- QA checks: Verify dimensional tolerances, surface uniformity, color consistency (ΔE tolerances by batch), and edge/scratch protection.

Sustainability considerations

- Lifecycle efficiency: Reduced time on-site and minimal finishing lowers fuel, labor, and waste. No repainting means ongoing maintenance resource savings.

- Durability: Impact-resistant, moisture-tolerant PVC extends service life, reducing replacement cycles.

- End-of-life: PVC skirting boards are widely recyclable. Where available, specify return-to-manufacturer or regional recycling streams for PVC profiles; confirm compatibility with local collection.

- Responsible sourcing: Request supplier statements on PVC feedstock sources, recycled content where available, and plant energy/management systems. Note that recycled content can affect surface finish and color consistency; qualify performance targets before committing.

- Regulatory interface: Expect increased attention to product environmental transparency (e.g., EPD-type disclosure) in public and large commercial tenders.

Historical evolution and product facts (from source)

- Installation advantages emerged with adhesive systems: widely accessible adhesives allow direct bonding to prepared surfaces, eliminating nails/screws and finishing steps (sanding/painting), saving significant fitting time while producing a tidy finish.

- Durability and maintenance: Modern white PVC skirting boards use 16 mm solid PVC cores with protective skins, resist bumps and scuffs, and require minimal upkeep—routine cleaning by wipe-down suffices; repainting is not necessary.

- Reference specification: 16 mm thickness; 5-unit packs (FOS125) commonly available; white color nearest RAL 9003.

Practical procurement playbook

- Define standards up front: US—ASTM and code requirements per project; Europe—ENs, fire behavior requirements, and RAL references (RAL 9003 for white).

- Lock accessories: Include corners, end caps, and door surrounds in the same batch to ensure color/finish uniformity.

- Manage finishes: Specify gloss and color tolerances; request and approve pre-installation samples from the intended production batch.

- Installation method: Choose adhesive-fix for speed and finish quality when substrates permit; include mechanical fix specifications where codes or conditions require.

- Logistics: Plan 4–8+ weeks lead time with buffers; protect millwork finishes with rack packaging and corner guards; account for seasonal temperature variations.

- Sustainability: Seek recycled-content options and end-of-life pathways; request supplier statements on materials, manufacturing practices, and energy/management systems.

Key takeaways

- White PVC skirting boards deliver measurable cost advantages through faster, cleaner installation, durable performance, and low ongoing maintenance.

- Specifiers should align performance standards (ASTM/EN), RAL references (white: RAL 9003), and installation methods to regional norms and building codes.

- Sustainability value is strongest when lifecycle efficiency, durability, and end-of-life recyclability are specified together and verified at sourcing.

Frequently Asked Questions (FAQs) for B2B Buyers of white pvc skirting board

Frequently Asked Questions (FAQs) for B2B Buyers of White PVC Skirting Board

1) What finishes and colors are available?

- Standard: White (RAL No.9003), a widely specified neutral white for B2B projects.

- Related finishes: White profiles are also offered on selected 10 mm square leg fascia SKUs (e.g., FW100, FW125, FW150, FW175) to support cohesive system detailing.

- Notes:

- Nearest RAL equivalents are provided for color matching; final tone should be verified against physical samples.

- Coordinate with adjacent products to minimize batch-to-batch color variation.

2) What are the key dimensions and packaging?

- Profile example: FOS (ogee shape) sold as individual units; information shows “Unit: 5” and “Units/Pack: 5,” which may indicate pricing/pack structure rather than length.

- Thickness: 16 mm solid PVC core and skin for impact resistance in commercial environments.

- Action: Request current length options, heights, and exact pack counts per SKU to align with project take-offs and logistics planning.

3) What installation method reduces time and rework?

- Adhesive-only installation is supported: widely available adhesives can be used to adhere PVC skirting and door surround systems, eliminating nails and screws.

- This method can reduce fitting time by up to 50% versus traditional mechanical fixing, and no sanding or painting is required.

- Action: Specify substrate condition (dry, dust-free, level) and confirm approved adhesive classes with the supplier’s technical data sheet.

4) How do the boards perform during use?

- Durable core: 16 mm thickness, solid PVC core and skin intended to withstand frequent bumps in commercial settings.

- Surface: Low-maintenance—clean with a damp cloth; repainting not required.

- Fit-and-forget material: Designed for long-lasting appearance with minimal upkeep.

5) What documentation and compliance details should be requested?

- Provide product data, installation guidance, and environmental statements.

- Ask for current performance characteristics such as:

- Impact resistance class or rating (e.g., IK rating)

- Reaction to fire classification

- VOC emissions or indoor air quality statements (e.g., AgBB, REACH, or equivalent)

- Lead-free declarations and safe-use guidance for adhesives

- Dimensional tolerances and compatibility with adjacencies (e.g., cladding, door surrounds, flooring transition heights)

- Where required, secure independent test reports or certifications (e.g., UKCA/CE or equivalent for target markets).

6) How do we ensure color consistency across batches and sites?

- Always order from a single production batch for each color; avoid mixed batches across zones.

- Request pre-delivery batch verification and keep one master reference sample on site.

- Note: All RAL numbers are nearest equivalents; visually confirm color match under the project’s lighting conditions.

7) What cleaning and maintenance program should we specify?

- Routine cleaning: wipe with a damp cloth or mild, pH-neutral detergent.

- Avoid abrasives and aggressive solvents that may damage the surface.

- Include cleaning notes in O&M manuals and establish a scheduled maintenance routine to preserve finish in high-traffic areas.

8) How should we structure a tender/specification submission for this product?

- Include: product SKU(s) (e.g., FOS), finish and RAL (e.g., White RAL No.9003), required thicknesses (e.g., 16 mm), installation method (adhesive-only, with substrate requirements), delivery format (lengths, pack counts), and requested documentation.

- Request: current technical data sheets, installation guides, performance test reports, and a batch/lead-time plan to align with the construction schedule.

- Add compliance clauses for safety (e.g., SDS for adhesives), environmental declarations (e.g., VOC/REACH), and fire performance.

- Consider pilot installations to verify fit, adhesion, and visual continuity before full roll-out.

If you need a ready-to-copy tender line-item or a consolidated technical request checklist, specify your target markets (USA/Europe) and procurement format (offtake, framework, or project-specific), and I’ll tailor the wording.

Illustrative Image (Source: Google Search)

Strategic Sourcing Conclusion and Outlook for white pvc skirting board

Strategic Sourcing Conclusion and Outlook for White PVC Skirting Boards

White PVC skirting boards deliver a clear B2B advantage: a fit‑and‑forget, professional finish that reduces time and lifecycle cost. Up to 50% faster installation is achievable with widely accessible adhesives—eliminating nails/screws and sanding/painting—while a 16 mm solid PVC core and skin provide durability for high‑traffic spaces. The pre‑finished, wipe‑clean surface stays RAL 9003 white without repainting, enabling predictable costs and consistent branding.

For USA and Europe distributors and installers, the product’s standardized thickness, stable core/skin, and minimal maintenance simplify specification and reduce rework risks. Buyers benefit from rapid turnaround and fewer consumables.

Strategic outlook:

– Adhesive‑based systems continue to replace mechanical fixing for speed and finish consistency.

– Specification for RAL 9003 white improves multi‑region color matching and batch control.

– Moisture‑stable, low‑VOC finishes support faster delivery and reduced on‑site QA issues.

Key specification snapshot:

| Attribute | Highlight |

| — | — |

| Profile | Ogee-shaped |

| Thickness | 16 mm |

| Finish | Pre‑finished, wipe‑clean |

| Color | White (RAL 9003) |

| Installation | Adhesive‑only, no nails/screws |

| Maintenance | Quick wipe; no repaint |

| Time savings | Up to 50% faster fitting |

Illustrative Image (Source: Google Search)

Recommendation: qualify suppliers on standardized thickness, core/skin consistency, adhesive compatibility, and color precision to RAL 9003. Lock in lead times and QA checks to sustain margins and reliable delivery across North America and Europe.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided is for informational purposes only. B2B buyers must conduct their own due diligence.