About WL Allotech

Founded in 2009, Changzhou WL Allotech Material Co., Ltd. has emerged as a trusted global supplier of advanced special alloy materials. We specialize in the development and production of high-performance materials for extreme environments across aerospace, energy, chemical processing, and industrial manufacturing.

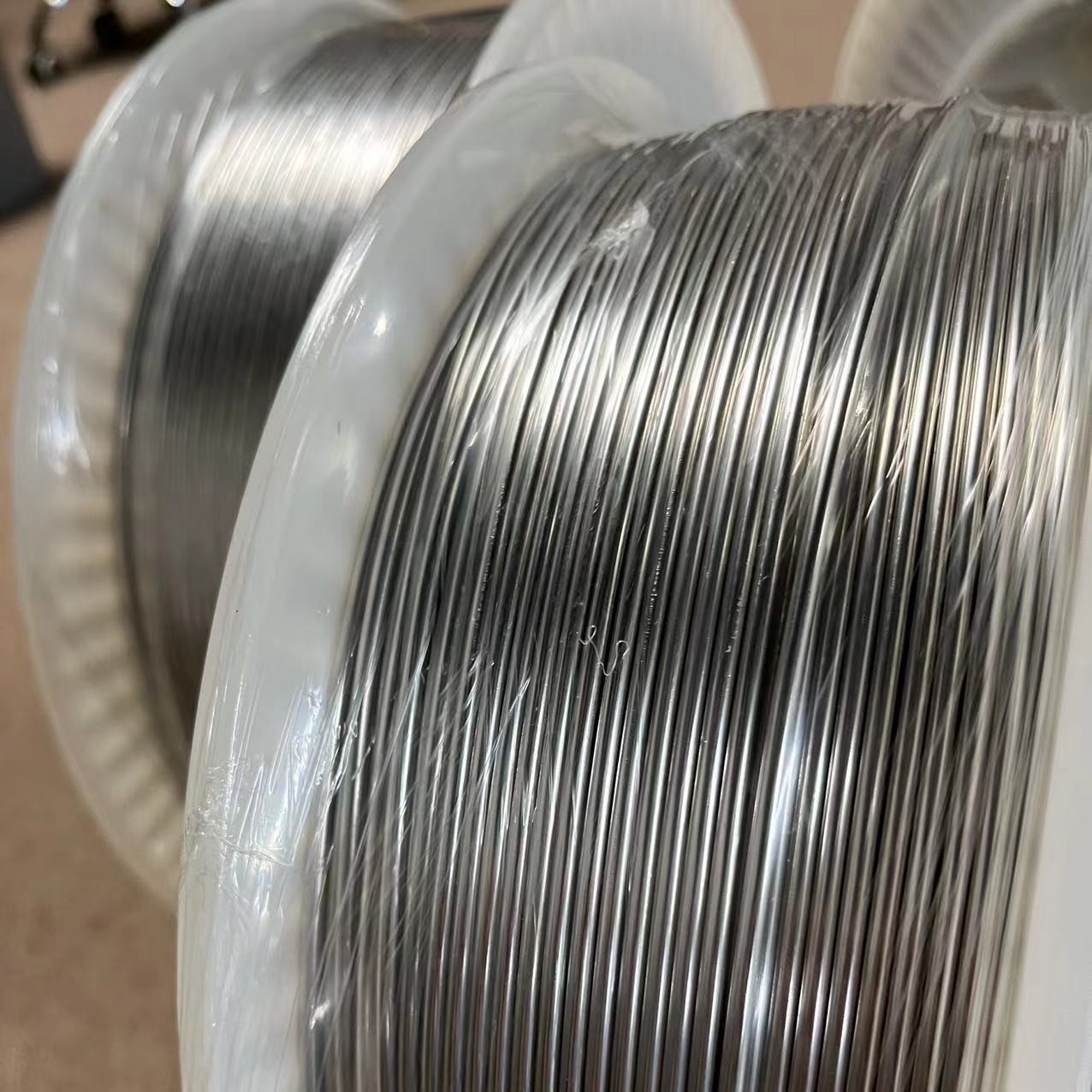

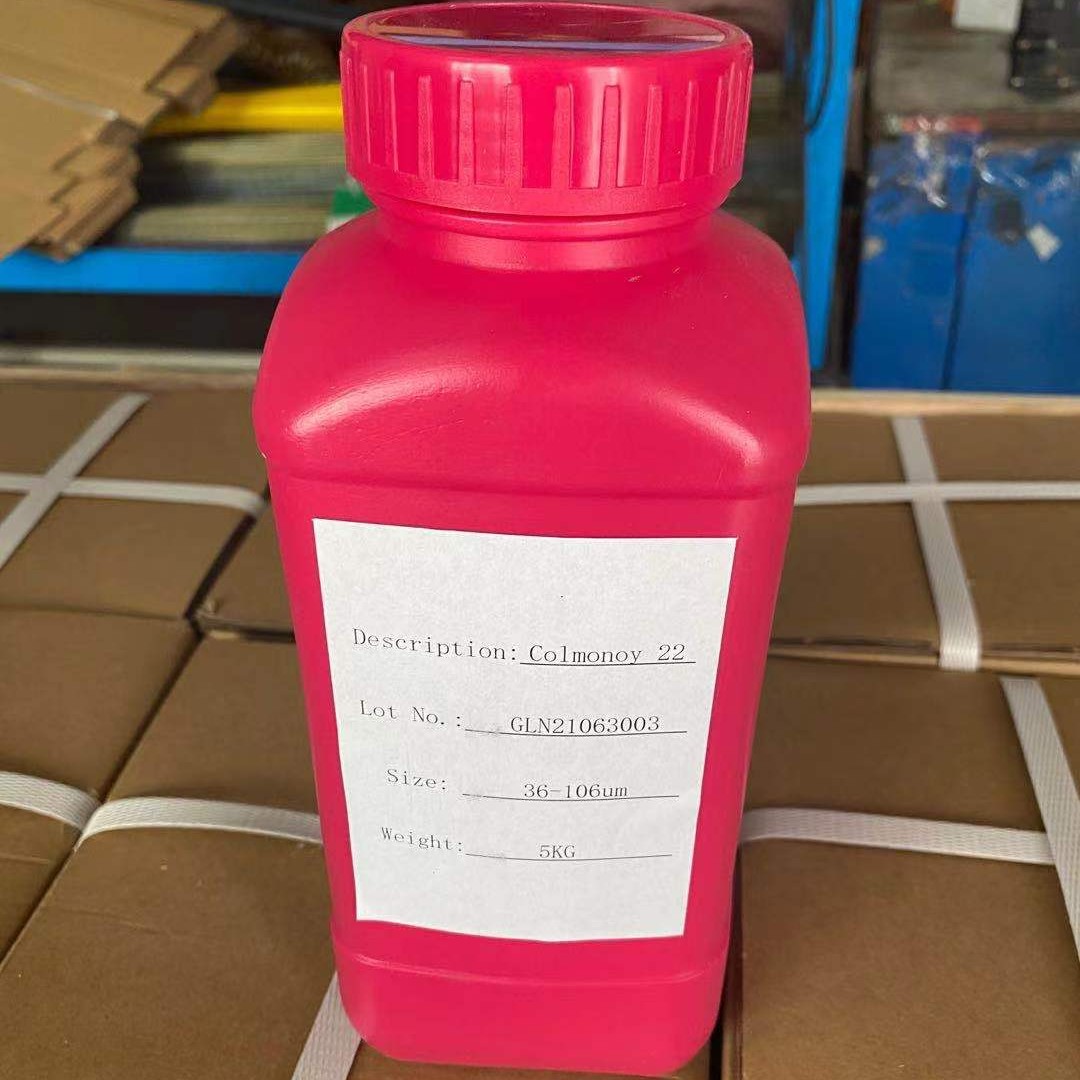

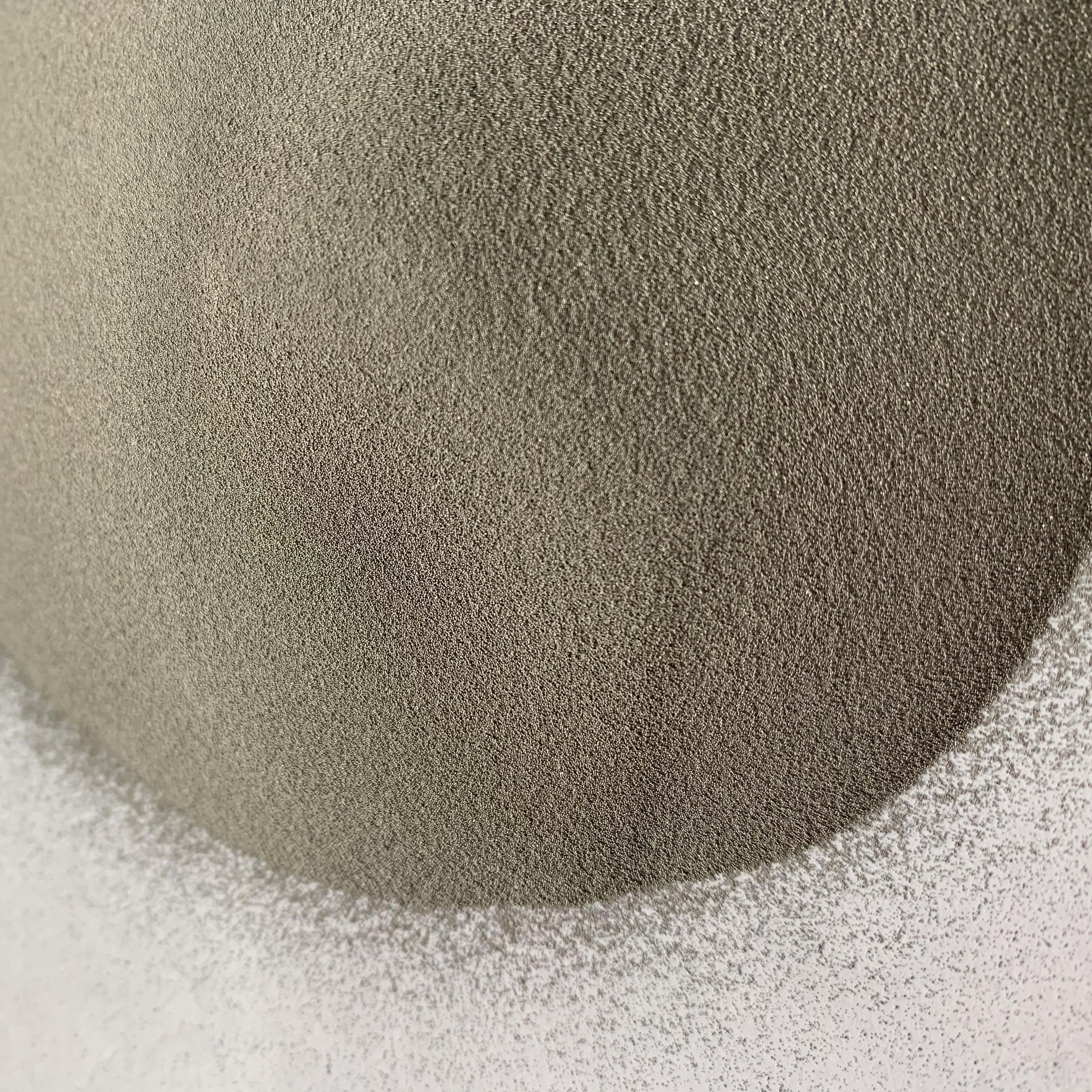

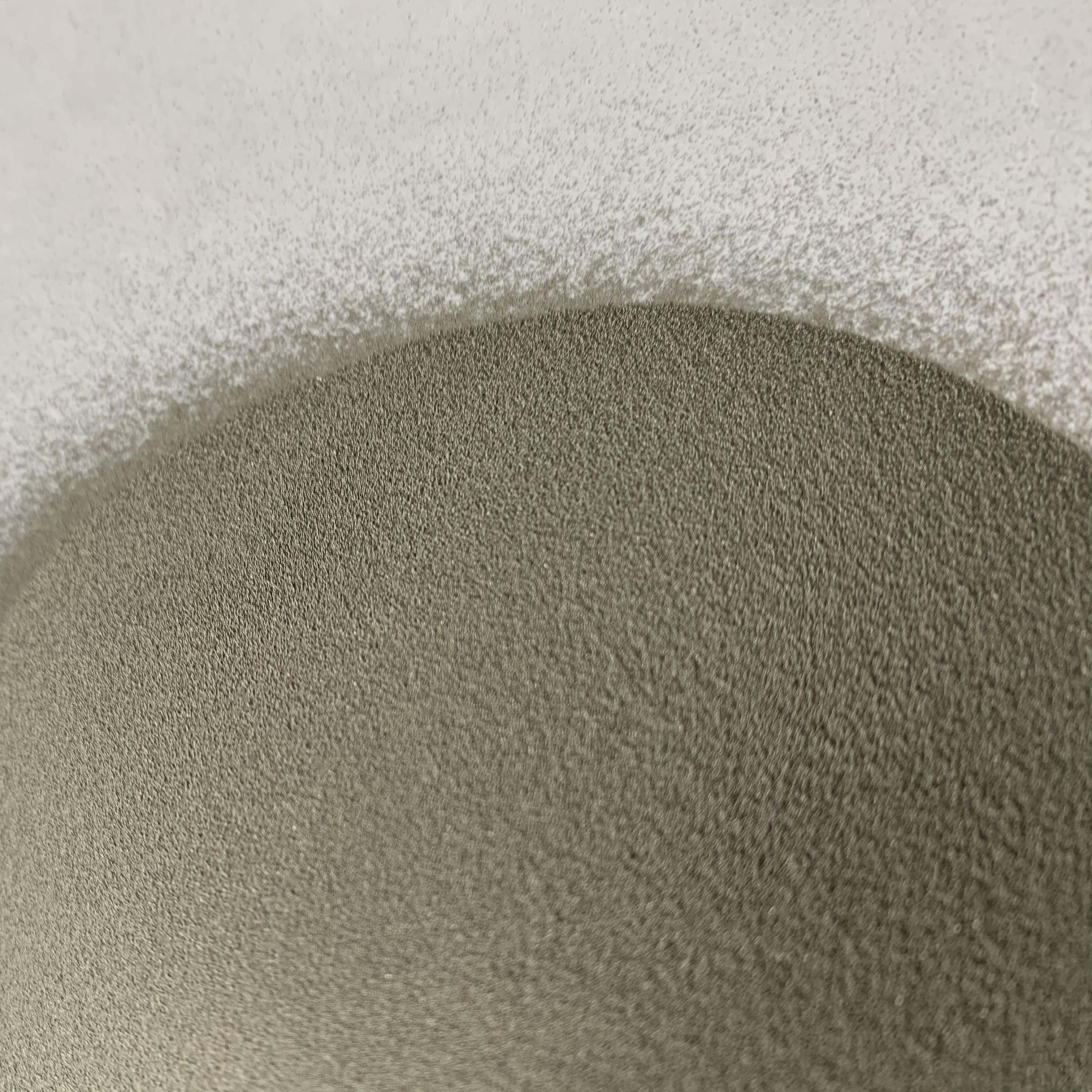

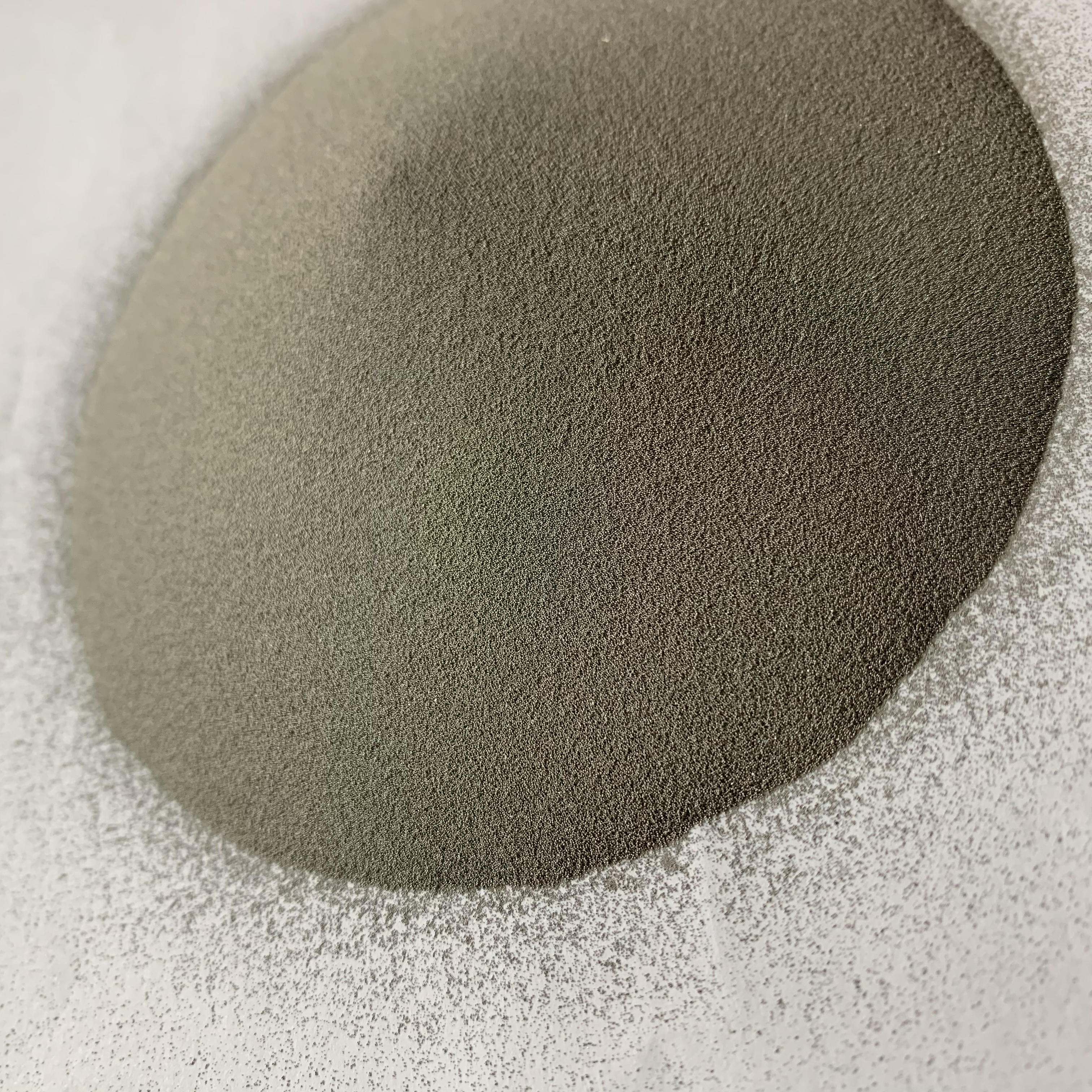

Our product portfolio includes precision alloys, high-temperature alloys, corrosion-resistant materials, hardfacing welding products, thermal spray materials, and additive manufacturing powders. With a commitment to innovation and quality, we deliver materials in various forms — wire, powder, rod, bar, plate, strip, tube, fittings, forgings, and mesh — tailored to meet the evolving needs of our clients.

2009

Founded

50+

Global Markets

_%E5%89%AF%E6%9C%AC.jpg)