Your Trusted Partner in High-Quality Mold Making

Since 2005, Zetar Mold has been delivering precision plastic injection molds and production solutions from our state-of-the-art facility in Shanghai, China. As an ISO 9001, ISO 13485, ISO 14001, and ISO 45001 certified manufacturer, we combine advanced engineering with rigorous quality control to bring your designs to life.

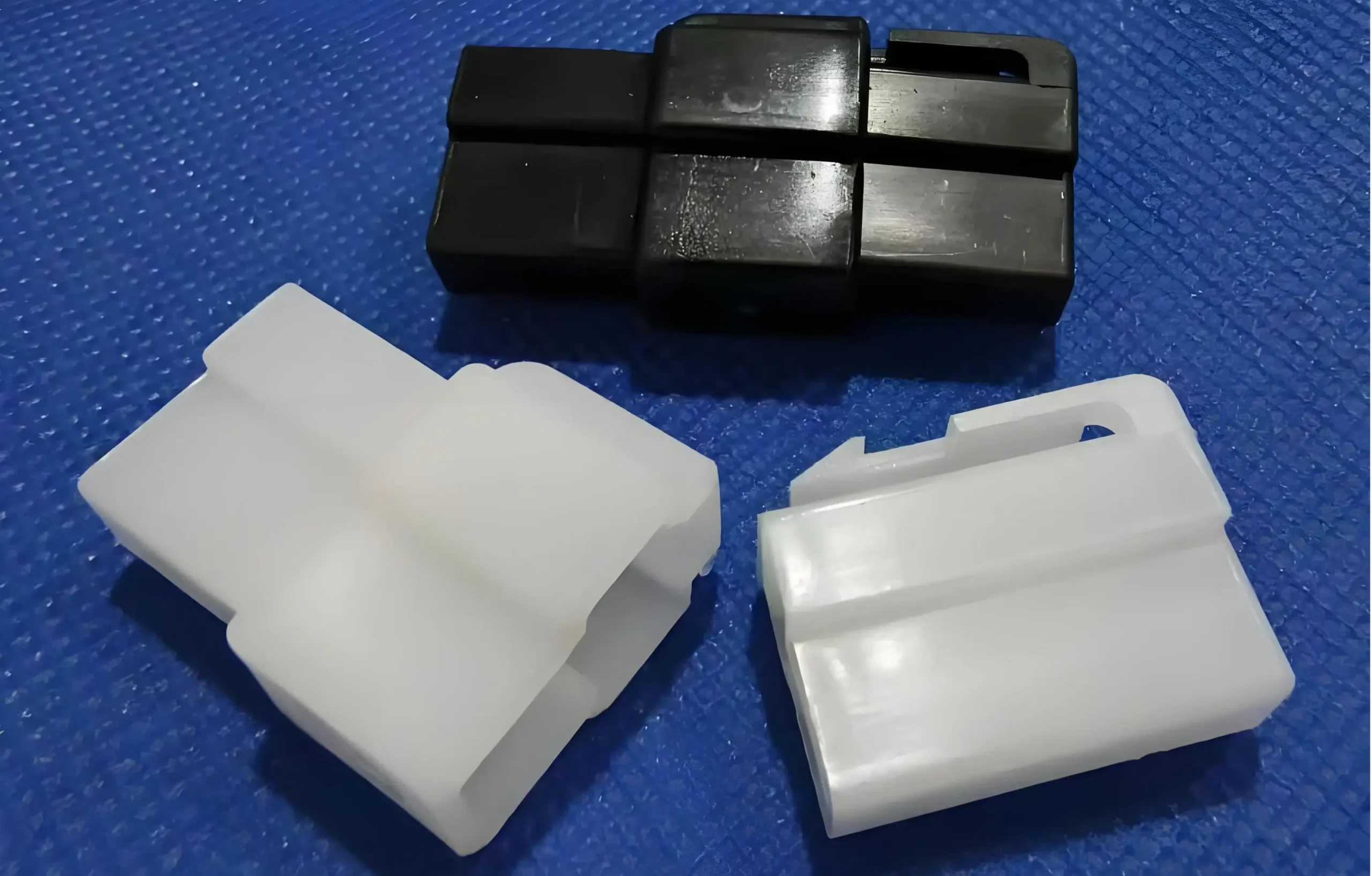

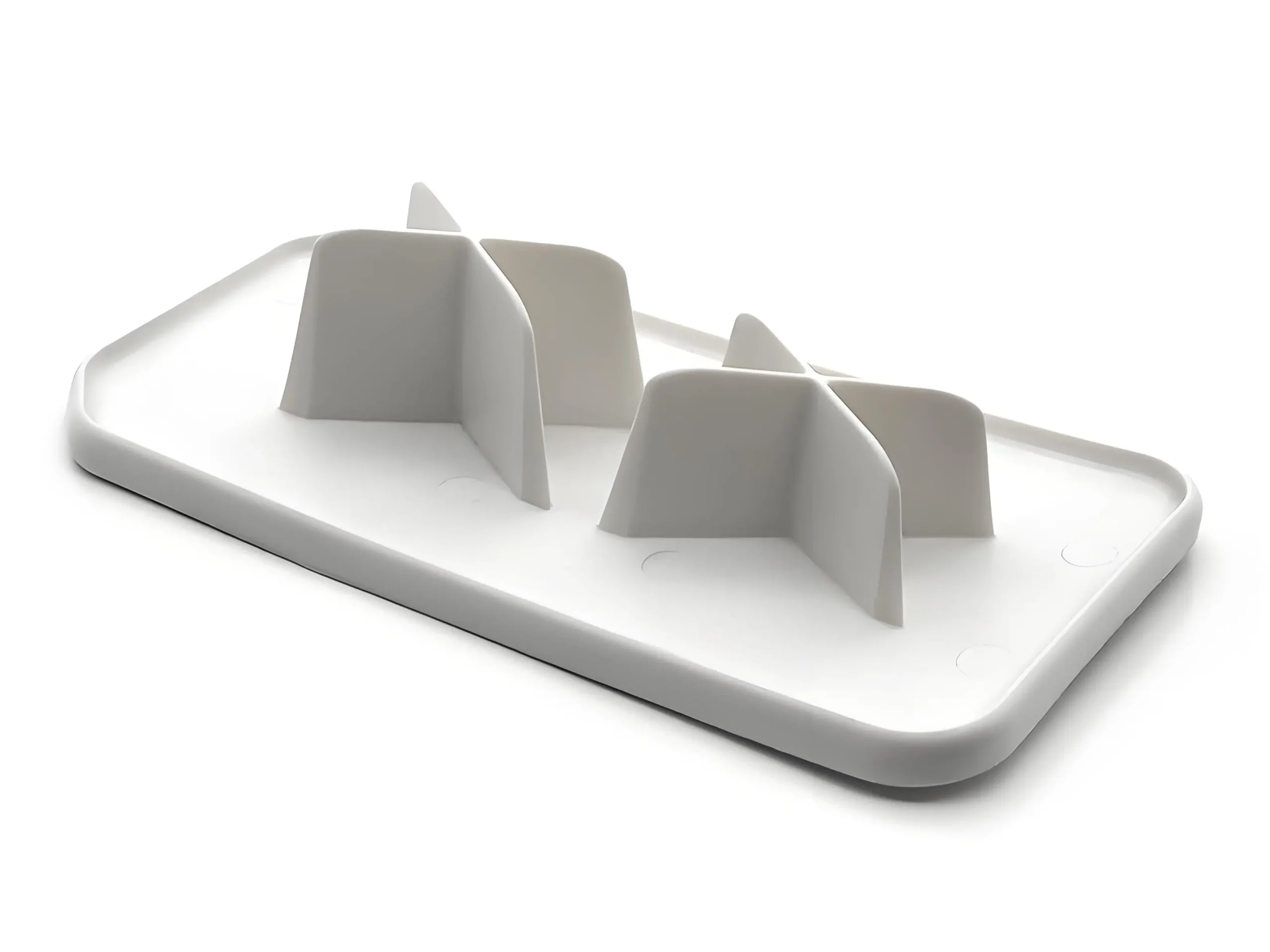

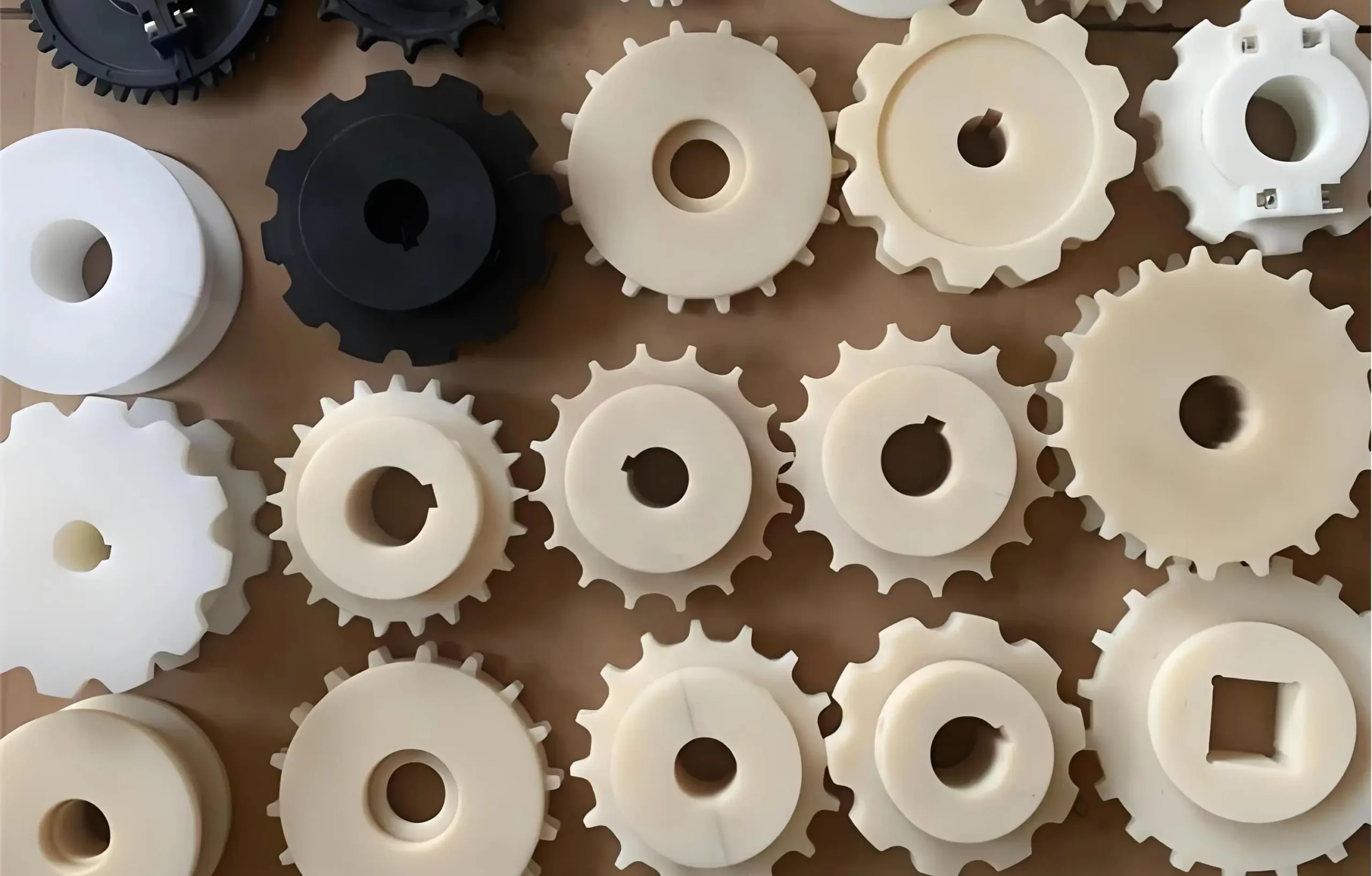

We specialize in full-service production — from concept and design to rapid prototyping, mold flow analysis, and high-volume manufacturing. Our team of 8 expert mold engineers ensures every project meets the highest standards of performance, durability, and cost-efficiency.

- Design for Manufacturing (DFM) & 3D Modeling

- Material Selection Guidance for Optimal Performance

- Rapid Prototyping with SLA, SLS, FDM & CNC

- End-to-End Production & Post-Processing