Precision Cemented Carbide

Solutions for Industry

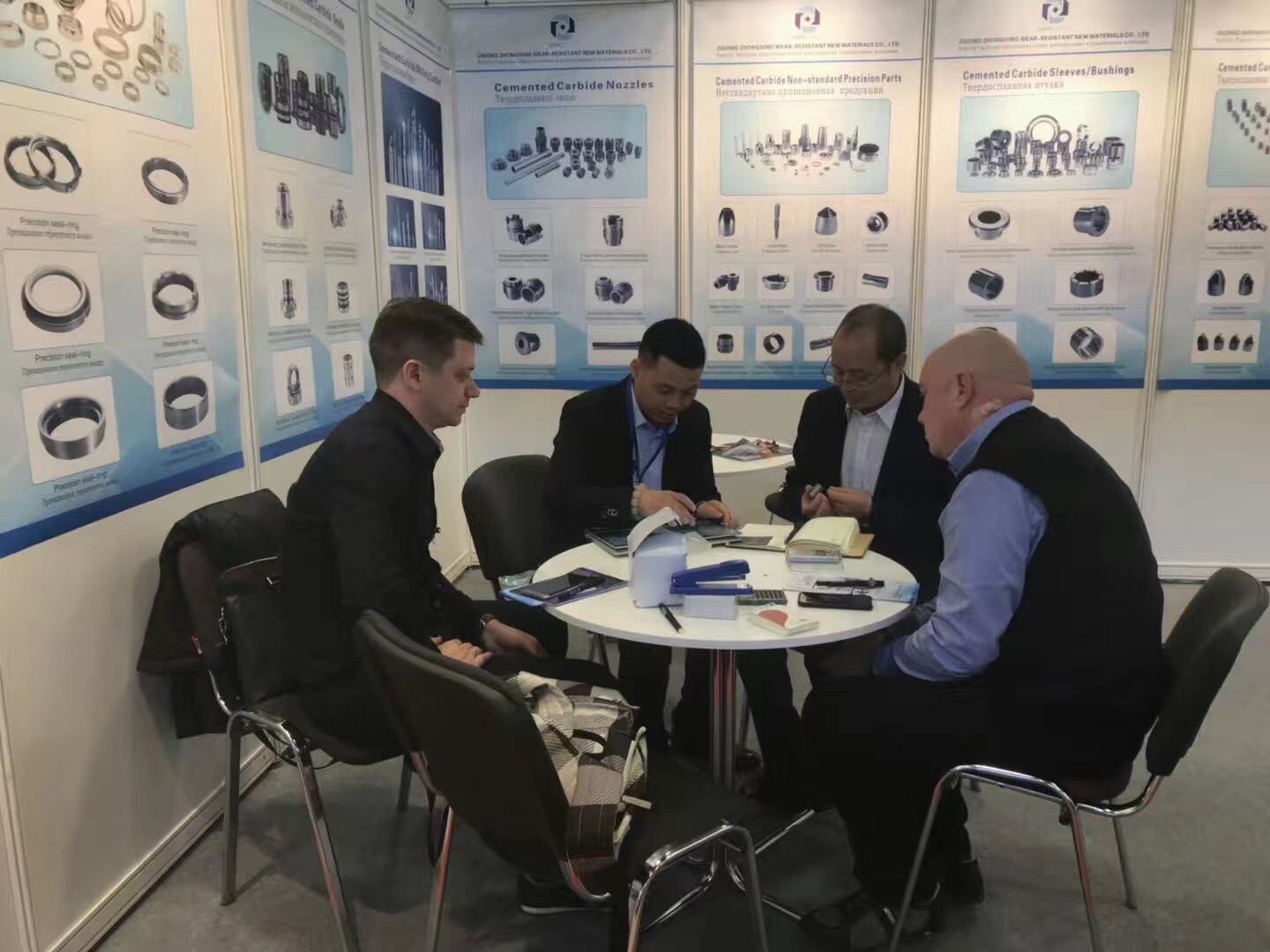

12+ years of expertise in manufacturing high-performance cemented tungsten carbide products — from axle sleeves and bushings to nozzles, seal rings, and custom precision parts for oil & gas, mining, construction, and industrial applications.